Bayanin Samfurin

Ana amfani da bututun ruwa da bututun ruwa sosai wajen haƙa mai da iskar gas, kuma bututun ruwa suna da matuƙar muhimmanci a masana'antar mai da iskar gas da ake amfani da su wajen haƙowa da jigilar hydrocarbons (mai da iskar gas) daga ma'ajiyar ƙasa zuwa saman ruwa. Suna taka muhimmiyar rawa wajen tabbatar da aminci, inganci, da ingancin ayyukan haƙo mai da samar da shi.

Bututu wani nau'in bututu ne da ake amfani da shi don jigilar ɗanyen mai da iskar gas daga saman mai ko layin iskar gas zuwa ƙasa bayan an gama haƙa ramin. Bututun bututu yana ba da damar matsin lamba da ake samu yayin aikin haƙa bututun. Ana samar da bututun kamar yadda ake samar da shi, amma ana buƙatar tsarin da ake kira "mai tayar da hankali" don kauri bututun bututun.

Ana amfani da kaskon don kare ramukan rijiyoyin da aka haƙa a ƙasa don mai. Ana amfani da shi kamar bututun haƙa, bututun kaskon rijiyar mai kuma yana ba da damar matsin lamba na axial, don haka ana buƙatar ƙarfe mai ƙarfi mai inganci. Kaskon OCTG manyan bututu ne da aka haɗa su da siminti a cikin ramin.

Bayani dalla-dalla

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Jerin Kaya na Karfe na ISO/API

| Lakabia | A waje diamita D mm | Nau'i layi tarob, c Tsarin Shaida da Hulɗa kg/m | Bango kauri t mm | Nau'in ƙarshen ƙarshe | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Nau'i na 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Duba bayanin kula a ƙarshen tebur. | ||||||||||||

| Lakabia | A waje diamita D mm | Nau'i layi tarob, c Tsarin Shaida da Hulɗa kg/m | Bango kauri t mm | Nau'in ƙarshen ƙarshe | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Nau'i na 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Duba bayanin kula a ƙarshen tebur. | ||||||||||||

| Lakabia | A waje diamita D mm | Nau'i layi tarob, c Tsarin Shaida da Hulɗa kg/m | Bango kauri t mm | Nau'in ƙarshen ƙarshe | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Nau'i na 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Ƙarshen da ba a iya misaltawa ba, S = Zaren da aka yi da gajere, L = Zaren da aka yi da dogon zare, B = Zaren da aka yi da buttress, E = Layi mai tsauri. | ||||||||||||

| ♦ Lakabi ne don bayanai da taimako wajen yin oda. ♦ An nuna nau'ikan layi na yau da kullun, waɗanda aka zare da kuma haɗe (shafi na 2) don bayani kawai. ♦ Yawan ƙarfen martensitic chromium (nau'ikan L80 9Cr da 13Cr) ya bambanta da ƙarfen carbon. Saboda haka, yawan da aka nuna bai dace da ƙarfen martensitic chromium ba. Ana iya amfani da ma'aunin gyara taro na 0,989. | ||||||||||||

| Lakabi | Diamita na waje D mm | Layi mai layi-layi taro kg/m | Kauri a bango t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Jerin bututun ƙarfe na ISO/API

| Lakabi | A waje diamita D mm | Layi mai lamba taroa, b | Bango mai kauri- ness t mm | Nau'in ƙarewac | |||||||||||

| Ba- haushi Tsarin Shaida da Hulɗa kg/m | Tsawo. haushi Tsarin Shaida da Hulɗa kg/m | Integ. haɗin gwiwa kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Tsarin Shaida da Hulɗa | EU Tsarin Shaida da Hulɗa | IJ | H40 | J55 | L80 | N80 Nau'i na 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1,900 1,900 1,900 1,900 1,900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Ƙarshen da ba a taɓa gani ba, N = Zare mara matsala da haɗewa, U = Zare mai ɓacin rai da haɗewa na waje, I = Haɗin gwiwa mai haɗaka. | |||||||||||||||

| ♦ An nuna jerin layi na yau da kullun, zare da haɗin kai (shafi na 2, 3, 4) don bayani kawai. ♦ Yawan ƙarfen martensitic chromium (nau'ikan L80 9Cr da 13Cr) ya bambanta da ƙarfen carbon. Saboda haka, yawan da aka nuna bai dace da ƙarfen martensitic chromium ba. Ana iya amfani da ma'aunin gyara taro na 0,989. ♦ Ana samun bututun da ba ya fashewa tare da haɗin kai na yau da kullun ko haɗin bevel na musamman. Ana samun bututun da ke fashewa na waje tare da haɗin kai na yau da kullun, na musamman, ko na musamman. | |||||||||||||||

Daidaitacce & Matsayi

Tubali da bututun ƙarfe Ma'auni na yau da kullun:

API 5CT J55,K55,L80,N80,P110,C90,T95,H40

Ƙarfin bututun API 5CT da bututun bututu:

(STC)Zare mai zagaye mai gajeren zango

(LC) Dogon zare mai zagaye

(BC)Maƙallin zaren maƙalli

Katin (XC)Mai layi mai tsauri

(NU) Bututun da ba ya tayar da hankali

(EU)Bututun da ke fitowa daga waje

(IJ)Bangon haɗin gwiwa mai haɗaka

Ya kamata a isar da kashin da bututun bisa ga haɗin da ke sama tare da ƙa'idodin API5CT / API.

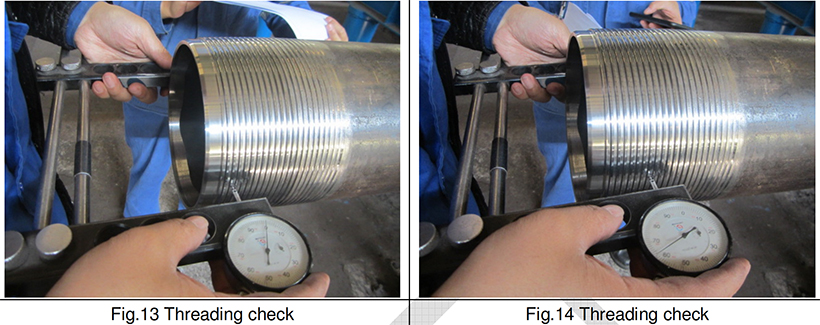

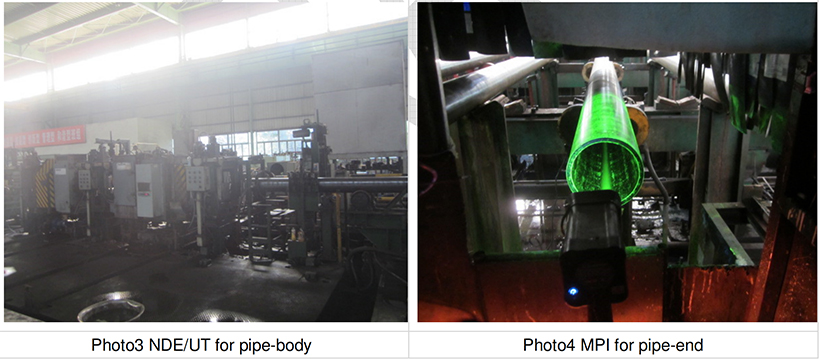

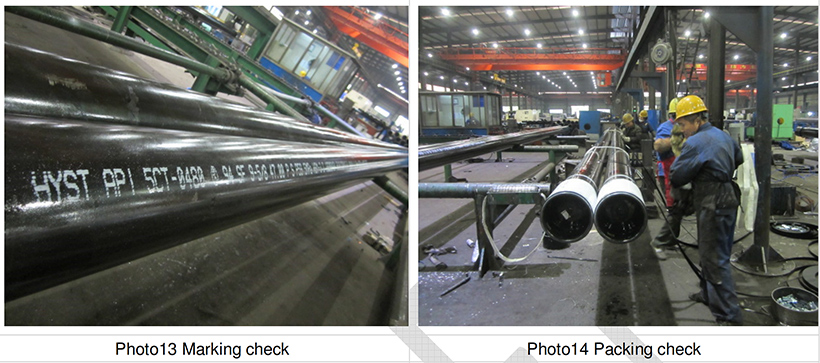

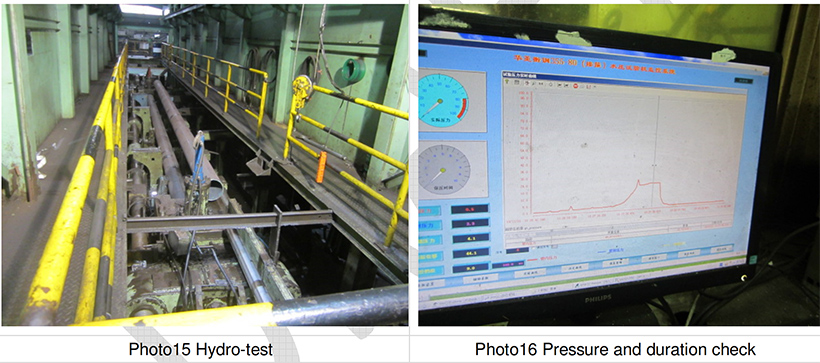

Sarrafa Inganci

Duba Kayan Danye, Binciken Sinadarai, Gwajin Inji, Duba Gani, Gwajin Tashin Hankali, Duba Girma, Gwajin Lanƙwasa, Gwajin Faɗi, Gwajin Tasiri, Gwajin DWT, Gwajin NDT, Gwajin Hydrostatic, Gwajin Tauri…..

Alamar, Zane kafin a kawo.

Shiryawa & Jigilar Kaya

Hanyar marufi ga bututun ƙarfe ta ƙunshi tsaftacewa, haɗa su wuri ɗaya, naɗe su, haɗa su wuri ɗaya, ɗaure su wuri ɗaya, sanya musu alama, sanya musu pallet (idan ya cancanta), sanya musu kwantena, adana su, rufe su, jigilar su, da kuma cire su. Nau'ikan bututun ƙarfe daban-daban da kayan aiki tare da hanyoyin tattara su daban-daban. Wannan tsari mai cikakken tsari yana tabbatar da cewa bututun ƙarfe suna jigilar su zuwa inda za su je cikin yanayi mafi kyau, a shirye don amfani da su.

Amfani & Aikace-aikace

Bututun ƙarfe suna aiki a matsayin ginshiƙin injiniyan masana'antu da na farar hula na zamani, suna tallafawa aikace-aikace iri-iri waɗanda ke ba da gudummawa ga ci gaban al'ummomi da tattalin arziki a duk duniya.

Bututun ƙarfe da kayan haɗin da Womic Steel ke samarwa ana amfani da su sosai don bututun mai, iskar gas, mai da ruwa, ayyukan gini da gini a bakin teku/a gefen teku, ayyukan gina tashar jiragen ruwa, haƙa, aikin ginin ƙarfe, tarin abubuwa da gada, da kuma bututun ƙarfe masu daidaito don samar da abin hawa, da sauransu...