Bayanin Samfurin

Mai ragewa:

Na'urar rage bututun ƙarfe tana aiki a matsayin muhimmin sashi na bututun, wanda ke ba da damar sauyawa daga manyan ramuka zuwa ƙananan ramuka daidai da ƙayyadaddun diamita na ciki.

Akwai manyan nau'ikan rage gudu guda biyu: mai daidaitawa da mai daidaitawa. Masu rage gudu suna yin tasiri ga rage girman ramin da ya dace, yana tabbatar da daidaiton layukan bututun da aka haɗa. Wannan tsari ya dace lokacin da kiyaye daidaiton kwararar ruwa yana da mahimmanci. Sabanin haka, masu rage gudu suna gabatar da bambanci tsakanin layukan bututun da ke tsakiya, suna biyan yanayi inda matakan ruwa ke buƙatar daidaito tsakanin bututun sama da ƙasa.

Mai Rage Ƙarfi

Mai Rage Mai Haɗaka

Masu rage amfani da bututun mai suna taka muhimmiyar rawa wajen daidaita bututun mai, wanda hakan ke sauƙaƙa sauyawa tsakanin bututun mai girma dabam-dabam. Wannan ingantawa yana ƙara ingancin tsarin gaba ɗaya da kuma aiki.

Elbow:

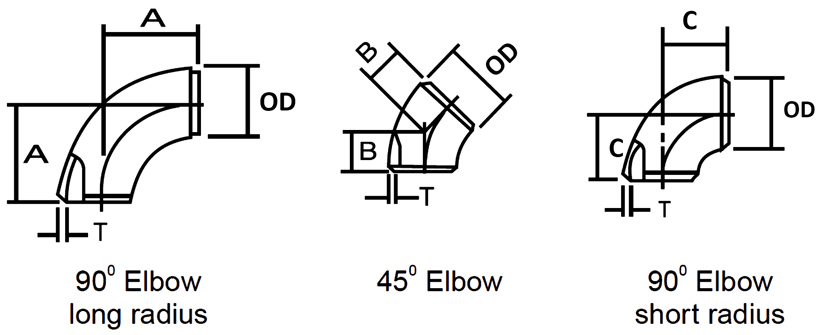

Gwiwar bututun ƙarfe tana da muhimmiyar rawa a cikin tsarin bututu, tana sauƙaƙa canje-canje a alkiblar kwararar ruwa. Tana samun amfani a cikin haɗa bututun da diamita iri ɗaya ko daban-daban, tana mayar da kwararar yadda ya kamata ta hanyar da ake so.

An rarraba gwiwar hannu bisa ga matakin canjin alkiblar ruwa da suke gabatarwa ga bututun mai. Kusurwoyin da aka saba gani sun haɗa da digiri 45, digiri 90, da digiri 180. Don aikace-aikace na musamman, kusurwoyi kamar digiri 60 da digiri 120 suna shiga cikin aiki.

Gilashin hannu suna faɗuwa cikin rarrabuwa daban-daban bisa ga radius ɗinsu dangane da diamita na bututu. Gajeren gwiwar hannu mai siffar Radius (SR elbow) yana da radius daidai da diamita na bututun, wanda hakan ya sa ya dace da bututun mai ƙarancin matsi, mai ƙarancin gudu, ko wurare masu iyaka inda sarari yake da tsada. Akasin haka, dogon gwiwar hannu mai siffar Radius (LR elbow), tare da radius sau 1.5 diamita na bututun, yana samun aikace-aikace a cikin bututun mai ƙarfin matsi da mai yawan kwarara.

Ana iya haɗa gwiwar hannu bisa ga hanyoyin haɗa bututunsu—Butt Welded Elbow, Socket Welded Elbow, da Threaded Elbow. Waɗannan bambance-bambancen suna ba da damar yin amfani da kayan aiki bisa ga nau'in haɗin da ake amfani da shi. Dangane da kayan aiki, gwiwar hannu ana yin su ne daga bakin ƙarfe, ƙarfe carbon, ko ƙarfe mai ƙarfe, wanda ya dace da takamaiman buƙatun jikin bawul.

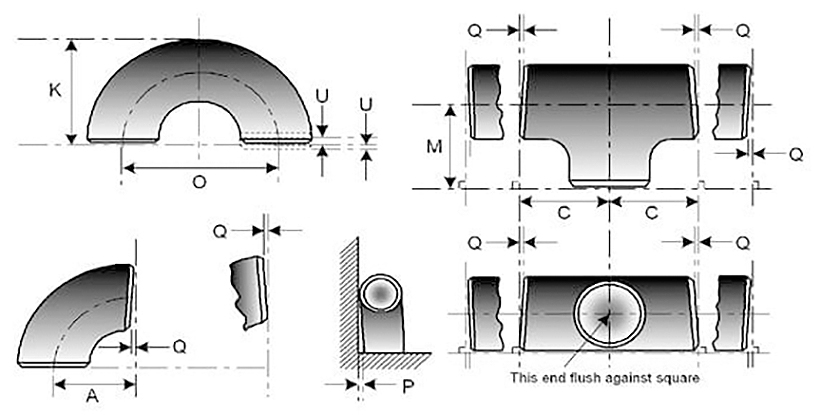

T-shirt:

Nau'in Bututun Karfe:

● Dangane da Diamita da Ayyukan Reshe:

● Daidaitaccen Tee

● Tee Mai Rage Kuzari (Tee Mai Rage Kuzari)

Dangane da Nau'in Haɗi:

● Butt Weld Tee

● Tee ɗin walda na Socket

● T-shirt mai zare

Dangane da Nau'in Kayan Aiki:

● Bututun Karfe na Carbon

● Tee na ƙarfe mai ƙarfe

● Tee ɗin Bakin Karfe

Aikace-aikacen bututun ƙarfe:

● Tayoyin bututun ƙarfe kayan aiki ne masu amfani da yawa waɗanda ke samun aikace-aikace a masana'antu daban-daban saboda ikonsu na haɗawa da kuma kwararar ruwa kai tsaye zuwa hanyoyi daban-daban. Wasu aikace-aikacen gama gari sun haɗa da:

● Man Fetur da Iskar Gas: Ana amfani da Tees don cire bututun mai don jigilar mai da iskar gas.

● Tace Man Fetur da Mai: A cikin matatun mai, tees suna taimakawa wajen sarrafa kwararar kayayyaki daban-daban yayin aikin tacewa.

● Tsarin Gyaran Ruwa: Ana amfani da tees a masana'antun tace ruwa don sarrafa kwararar ruwa da sinadarai.

● Masana'antun Sinadarai: Tees suna taka rawa wajen sarrafa sinadarai ta hanyar jagorantar kwararar sinadarai da abubuwa daban-daban.

● Bututun Tsafta: A cikin abinci, magunguna, da sauran masana'antu, bututun tsafta suna taimakawa wajen kiyaye yanayin tsafta a jigilar ruwa.

● Tashoshin Wutar Lantarki: Ana amfani da tees a tsarin samar da wutar lantarki da rarrabawa.

● Injina da Kayan Aiki: Ana haɗa tees cikin injuna da kayan aiki daban-daban na masana'antu don sarrafa ruwa.

● Musayar Zafi: Ana amfani da tees a tsarin musayar zafi don sarrafa kwararar ruwan zafi da sanyi.

Tees ɗin bututun ƙarfe muhimman abubuwa ne a cikin tsarin da yawa, suna ba da sassauci da iko kan rarrabawa da alkiblar ruwa. Zaɓin kayan da nau'in tees ɗin ya dogara da abubuwa kamar nau'in ruwan da ake jigilarwa, matsin lamba, zafin jiki, da takamaiman buƙatun aikace-aikacen.

Bayani kan Murfin Bututun Karfe

Murfin bututun ƙarfe, wanda kuma ake kira da toshe ƙarfe, wani abu ne da ake amfani da shi don rufe ƙarshen bututu. Ana iya haɗa shi da ƙarshen bututun ko a haɗa shi da zaren waje na bututun. Murfin bututun ƙarfe yana aiki ne don rufewa da kare kayan haɗin bututu. Waɗannan murfukan suna zuwa da siffofi daban-daban, gami da murfukan hemispherical, elliptical, dish, da spiral caps.

Siffofi na Murfin Convex:

● Murfin Hemisphere

● Murfin Elliptical

● Murfin Taliya

● Murfin Siffa

Maganin Haɗi:

Ana amfani da maƙullan don yanke sauye-sauye da haɗin bututu. Zaɓin maganin haɗin ya dogara da takamaiman buƙatun aikace-aikacen:

● Haɗin Weld na Butt

● Haɗin Walda na Soket

● Haɗin Zare

Aikace-aikace:

Murfin ƙarshe yana da amfani iri-iri a fannoni daban-daban kamar sinadarai, gini, takarda, siminti, da gina jiragen ruwa. Suna da amfani musamman don haɗa bututu masu diamita daban-daban da kuma samar da shinge mai kariya ga ƙarshen bututun.

Nau'in Murfin Bututun Karfe:

Nau'in Haɗi:

● Murfin Walda na Butt

● Murfin Walda na Soket

● Nau'in Kayan Aiki:

● Murfin Bututun Karfe na Carbon

● Murfin Bakin Karfe

● Murfin Karfe Mai Alloy

Bayani game da Lanƙwasa bututun ƙarfe

Lanƙwasa bututun ƙarfe wani nau'in bututu ne da ake amfani da shi don canza alkiblar bututun. Duk da yake yana kama da gwiwar hannu na bututu, lanƙwasa bututun ya fi tsayi kuma yawanci ana ƙera shi ne don takamaiman buƙatu. Lanƙwasa bututun yana zuwa a cikin girma daban-daban, tare da matakai daban-daban na lanƙwasa, don dacewa da kusurwoyin juyawa daban-daban a cikin bututun.

Nau'in Lanƙwasa da Inganci:

Lanƙwasa ta 3D: Lanƙwasa mai radius sau uku diamita na bututun da ba a saba gani ba. Ana amfani da shi sosai a cikin bututun mai dogaye saboda lanƙwasa mai laushi da kuma canjin alkibla mai inganci.

Lanƙwasa 5D: Wannan lanƙwasa yana da radius sau biyar diamita na bututun da ba a san shi ba. Yana samar da sauyi mai santsi a alkibla, wanda hakan ya sa ya dace da bututun mai tsawo yayin da yake kiyaye ingancin kwararar ruwa.

Biyan Kuɗi don Canje-canje na Digiri:

Lanƙwasa 6D da 8D: Ana amfani da waɗannan lanƙwasa, tare da radi sau shida da sau takwas diamita na bututun da ba a san shi ba, don rama ƙananan canje-canje a cikin alkiblar bututun. Suna tabbatar da sauyawa a hankali ba tare da katse kwararar ruwa ba.

Lanƙwasa bututun ƙarfe muhimmin abu ne a cikin tsarin bututu, wanda ke ba da damar sauye-sauyen alkibla ba tare da haifar da hayaniya ko juriya ga kwararar ruwa ba. Zaɓin nau'in lanƙwasa ya dogara da takamaiman buƙatun bututun, gami da matakin canjin alkibla, sararin da ake da shi, da kuma buƙatar kiyaye halayen kwarara masu inganci.

Bayani dalla-dalla

| ASME B16.9: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

| EN 10253-1: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Kauri |

| JIS B2311: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

| DIN 2605: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

| GB/T 12459: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

An rufe girman bututun gwiwar hannu da ASME B16.9. Duba teburin da ke ƙasa don girman girman gwiwar hannu 1/2" zuwa 48".

| Girman Bututu Marasa Girma | DIMITA TA WAJE | CIBIYAR ZUWA ƘARSHE | ||

| Inci. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 38 | 19 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

| Duk Girman suna cikin mm | ||||

Tsarin Bututun Haƙuri kamar yadda ASME B16.9 ta tanadar

| Girman Bututu Marasa Girma | DUKKAN ABUBUWAN DA AKA SAMU | DUKKAN ABUBUWAN DA AKA SAMU | DUKKAN ABUBUWAN DA AKA SAMU | Gwiwar hannu da kuma T-shirts | 180 DEG MAYAR DA LAUNAWA | 180 DEG MAYAR DA LAUNAWA | 180 DEG MAYAR DA LAUNAWA | MASU RAGEWA |

MAI HULA |

| NPS | OD a Bevel (1), (2) | ID a Ƙarshe | Kauri a Bango (3) | Girman Tsakiya zuwa Ƙarshe A, B, C, M | Tsakiya-zuwa-Cibiyar O | Komawa-da-Fuska K | Daidaita Ƙarshen U | Jimlar Tsawon H | Jimlar Tsawon E |

| ½ zuwa 2½ | 0.06 | 0.03 | Ba kasa da kashi 87.5% na kauri mara suna ba | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 zuwa 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 zuwa 8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| 10 zuwa 18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| Daga 20 zuwa 24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| Daga 26 zuwa 30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| Daga 32 zuwa 48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 |

| Girman Bututu Marasa Amfani NPS | JURIN ANGULARITY | JURIN ANGULARITY | AN BA DA DUKKAN GIRMA A INCI. JURIN YA DACE DA KARI DA KASA SAI DAI KAMAR YADDA AKA SANAR. |

|

| Kashe Kusurwar Q | Daga Jirgin Sama P | (1) Ba tare da zagaye ba shine jimlar ƙimar da ta dace da ƙarin da kuma rashin haƙuri. (2) Wannan haƙurin ba zai iya aiki a yankunan da aka gina kayan haɗin gwiwa ba inda ake buƙatar ƙarin kauri na bango don biyan buƙatun ƙira na ASME B16.9. (3) Mai siye ne zai ƙayyade diamita na ciki da kauri na bango na musamman a ƙarshensa. (4) Sai dai idan mai siye ya ƙayyade wani abu daban, waɗannan haƙurin sun shafi diamita na ciki na asali, wanda yayi daidai da bambanci tsakanin diamita na waje na asali da kuma kauri na bango na asali sau biyu. |

| ½ zuwa 4 | 0.03 | 0.06 | |

| 5 zuwa 8 | 0.06 | 0.12 | |

| 10 zuwa 12 | 0.09 | 0.19 | |

| Daga 14 zuwa 16 | 0.09 | 0.25 | |

| Daga 18 zuwa 24 | 0.12 | 0.38 | |

| Daga 26 zuwa 30 | 0.19 | 0.38 | |

| Daga 32 zuwa 42 | 0.19 | 0.50 | |

| Daga 44 zuwa 48 | 0.18 | 0.75 |

Daidaitacce & Matsayi

| ASME B16.9: Kayan Aikin Walda na Butt da Aka Yi a Masana'anta | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| EN 10253-1: Kayan Bututun Walda na Butt-Welding - Kashi na 1: Karfe na Carbon da aka yi da hannu don Amfani Gabaɗaya kuma Ba tare da takamaiman buƙatun dubawa ba | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| JIS B2311: Kayan Aikin Bututun Walda na Karfe don Amfani na Yau da Kullum | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| DIN 2605: Kayan Bututun Walda na Karfe: Gilashin hannu da lanƙwasa tare da Rage Matsi | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| GB/T 12459: Kayan Bututun Bututu Marasa Sulɓi Na Karfe | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

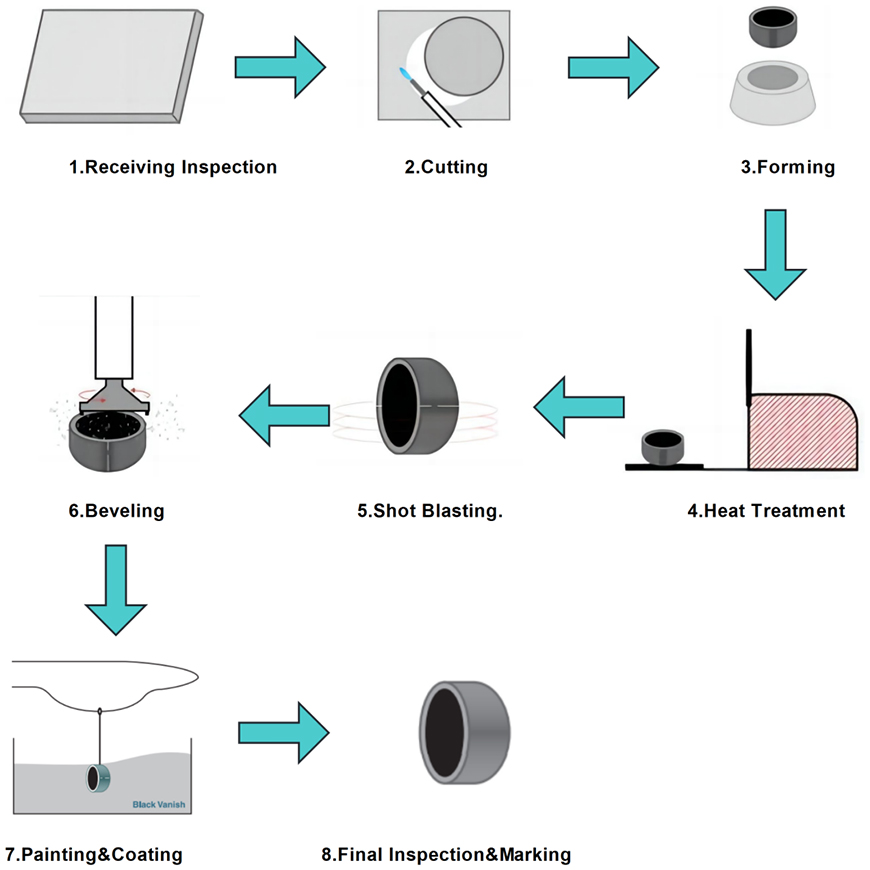

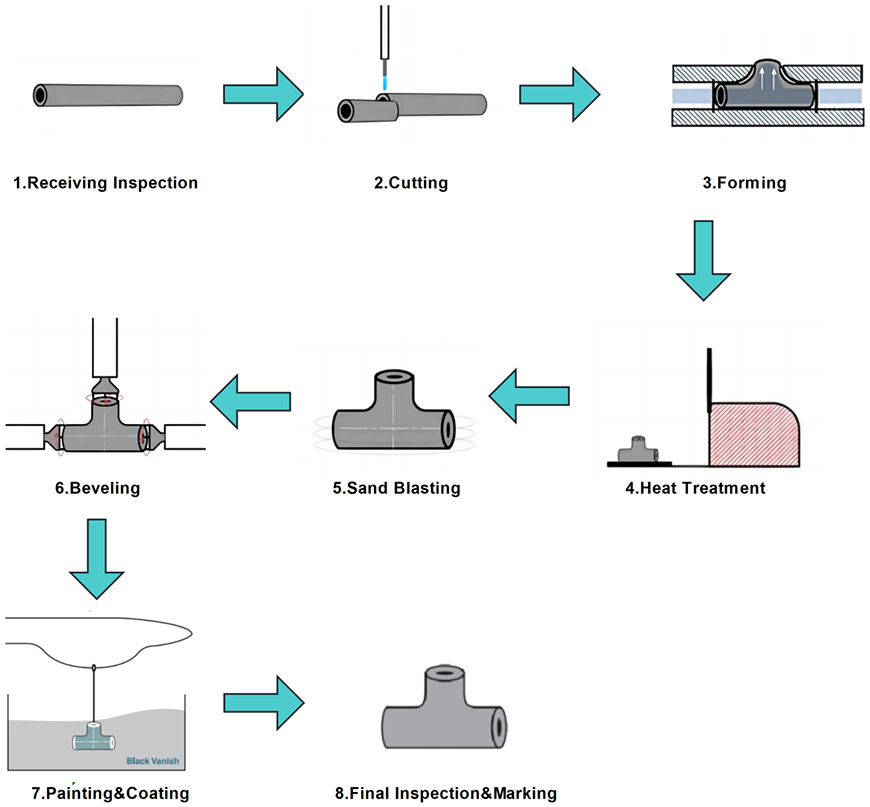

Tsarin Masana'antu

Tsarin Masana'antar Hulɗa

Tsarin Kera Tee

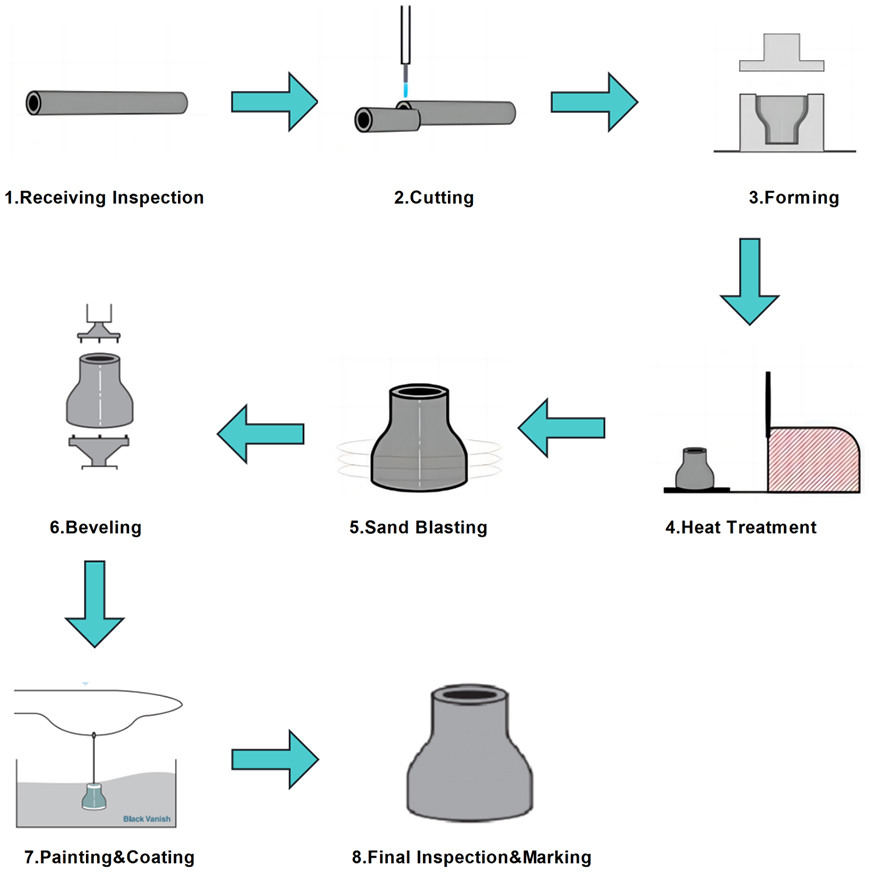

Tsarin Masana'antar Rage Rage

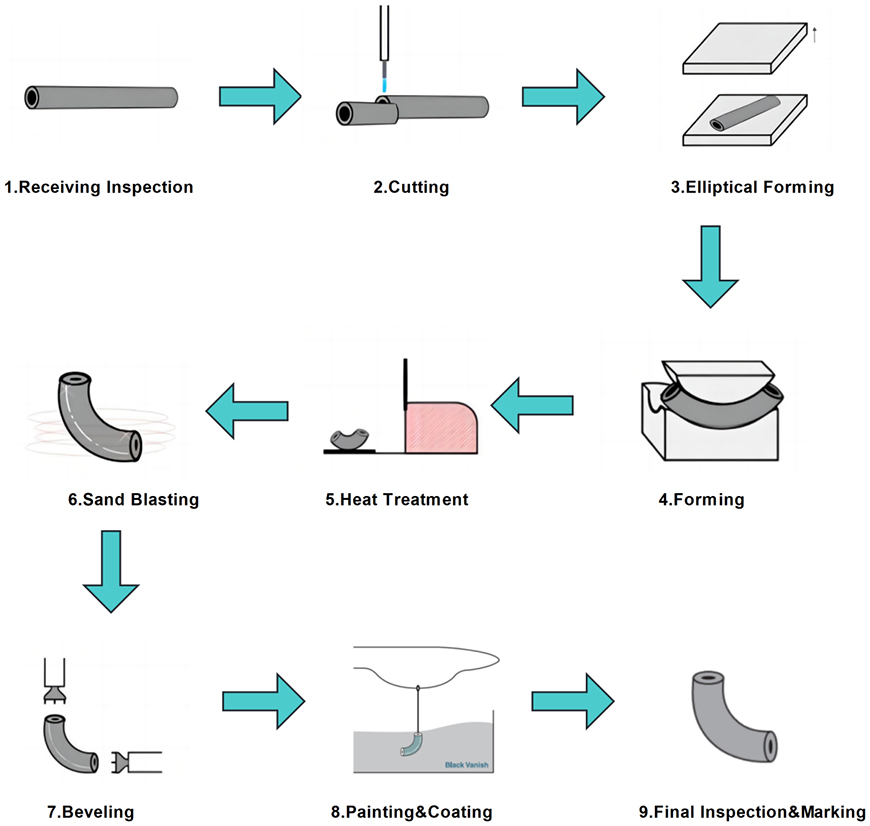

Tsarin Kera Gwiwar Elbow

Sarrafa Inganci

Duba Kayan Danye, Binciken Sinadarai, Gwajin Inji, Duba Gani, Duba Girma, Gwajin Lanƙwasa, Gwajin Faɗi, Gwajin Tasiri, Gwajin DWT, Gwajin Ba Mai Lalacewa Ba, Gwajin Tauri, Gwajin Matsi, Gwajin Zubar Kujeru, Gwajin Aikin Gudawa, Gwajin Karfin Karfi da Tuƙa, Zane da Duba Shafi, Bitar Takardu…..

Amfani & Aikace-aikace

Duba Kayan Danye, Binciken Sinadarai, Gwajin Inji, Duba Gani, Duba Girma, Gwajin Lanƙwasa, Gwajin Faɗi, Gwajin Tasiri, Gwajin DWT, Gwajin Ba Mai Lalacewa Ba, Gwajin Tauri, Gwajin Matsi, Gwajin Zubar Kujeru, Gwajin Aikin Gudawa, Gwajin Karfin Karfi da Tuƙa, Zane da Duba Shafi, Bitar Takardu…..

● Haɗi

● Sarrafa Alƙawari

● Tsarin Guduwar Ruwa

● Raba Kafafen Yaɗa Labarai

● Haɗa ruwa

● Tallafi da Anchoring

● Kula da Zafin Jiki

● Tsafta da Rashin Tsafta

● Tsaro

● Abubuwan da suka shafi Kyau da Muhalli

A taƙaice, kayan haɗin bututu abubuwa ne masu mahimmanci waɗanda ke ba da damar jigilar ruwa da iskar gas cikin inganci, aminci, da kuma sarrafawa a fannoni daban-daban na masana'antu. Amfaninsu daban-daban suna ba da gudummawa ga aminci, aiki, da amincin tsarin sarrafa ruwa a wurare marasa adadi.

Shiryawa & Jigilar Kaya

A Womic Steel, mun fahimci mahimmancin marufi mai aminci da jigilar kaya mai inganci idan ana maganar isar da kayan aikin bututunmu masu inganci zuwa ƙofar gidanku. Ga taƙaitaccen bayani game da hanyoyin marufi da jigilar kaya don amfaninku:

Marufi:

An shirya kayan aikin bututunmu a hankali don tabbatar da cewa sun isa gare ku cikin kyakkyawan yanayi, a shirye don buƙatunku na masana'antu ko kasuwanci. Tsarin marufi namu ya haɗa da waɗannan mahimman matakai:

● Duba Inganci: Kafin a rufe dukkan bututu, ana duba ingancinsu sosai domin tabbatar da cewa sun cika ƙa'idodinmu masu tsauri na aiki da kuma sahihanci.

● Rufin Kariya: Dangane da nau'in kayan da aka yi amfani da su, kayan aikinmu na iya samun rufin kariya don hana tsatsa da lalacewa yayin jigilar kaya.

● Haɗawa Mai Tsaro: Ana haɗa kayan haɗin tare cikin aminci, don tabbatar da cewa sun kasance masu karko kuma an kare su a duk lokacin jigilar kaya.

● Lakabi da Takardu: Kowace fakiti an yi mata lakabi da muhimman bayanai, gami da ƙayyadaddun bayanai na samfura, adadi, da duk wani umarni na musamman na sarrafa su. Takardu masu dacewa, kamar takaddun shaida na bin ƙa'ida, suma an haɗa su.

● Marufi na Musamman: Za mu iya ɗaukar buƙatun marufi na musamman bisa ga buƙatunku na musamman, tare da tabbatar da cewa an shirya kayan aikinku daidai yadda ake buƙata.

Jigilar kaya:

Muna haɗin gwiwa da abokan hulɗar jigilar kaya masu daraja don tabbatar da isar da kaya mai inganci da kan lokaci zuwa wurin da kuka ƙayyade. Ƙungiyar jigilar kayayyaki tamu tana inganta hanyoyin jigilar kaya don rage lokutan jigilar kaya da rage haɗarin jinkiri. Ga jigilar kaya ta ƙasashen waje, muna kula da duk takaddun kwastam da suka wajaba da bin ƙa'idodi don sauƙaƙe share kwastam cikin sauƙi. Muna ba da zaɓuɓɓukan jigilar kaya masu sassauƙa, gami da jigilar kaya cikin sauri don buƙatun gaggawa.