Bayanin Samfurin

Bayanan Daidaitacce - ASME/ANSI B16.5 & B16.47 - Bututun Flanges da Kayan Aiki Masu Flanged

Ma'aunin ASME B16.5 ya ƙunshi fannoni daban-daban na flanges ɗin bututu da kayan haɗin flanged, gami da ƙimar zafin jiki na matsin lamba, kayan aiki, girma, juriya, alama, gwaji, da kuma tsara buɗewa ga waɗannan abubuwan haɗin. Wannan ma'aunin ya haɗa da flanges tare da sunayen aji na kimantawa waɗanda suka kama daga 150 zuwa 2500, waɗanda suka shafi girma daga NPS 1/2 zuwa NPS 24. Yana ba da buƙatu a cikin raka'o'in ma'auni da na Amurka. Yana da mahimmanci a lura cewa wannan ma'aunin ya takaita ga flanges da kayan haɗin flanged da aka yi daga kayan siminti ko na ƙirƙira, gami da flanges makafi da takamaiman flanges masu ragewa da aka yi daga kayan siminti, na ƙirƙira, ko na faranti.

Don flanges ɗin bututu da kayan haɗin flanges waɗanda suka fi girman NPS 24", ya kamata a yi amfani da ASME/ANSI B16.47.

Nau'in Flange da Aka Fi Sani

● Flanges masu zamewa: Waɗannan flanges galibi ana samun su a cikin ANSI Class 150, 300, 600, 1500 & 2500 har zuwa NPS 24". Ana "zame su" a kan bututun ko ƙarshen da aka haɗa sannan a haɗa su a wuri ɗaya, wanda ke ba da damar walda na fillet a ciki da wajen flange. Ana amfani da nau'ikan ragewa don rage girman layi lokacin da sarari ya yi ƙasa.

● Ƙwayoyin Wuya Masu Lanƙwasa: Waɗannan ƙusoshin suna da wani dogon cibiya mai kauri da kuma sauƙin sauyawa na kauri, wanda ke tabbatar da cikakken haɗin walda zuwa bututu ko wurin da aka haɗa. Ana amfani da su a cikin mawuyacin yanayi na aiki.

● Faɗin Haɗin Lap: Idan aka haɗa su da ƙarshen stub, ana zame flanges ɗin haɗin gwiwa a kan madaurin ƙarshen stub kuma a haɗa su ta hanyar walda ko wasu hanyoyi. Tsarin su mara sassauƙa yana ba da damar daidaitawa cikin sauƙi yayin haɗawa da warwarewa.

● Faɗin Baya: Waɗannan faɗin ba su da fuska mai ɗagawa kuma ana amfani da su tare da zoben baya, suna ba da mafita masu araha ga haɗin faɗin.

● Fitilun Zare (Masu Sulke): An gaji da daidaita takamaiman bututu a cikin diamita, ana ƙera fitilun zare da zaren bututu mai kauri a gefen baya, musamman don ƙananan bututun huda.

● Flanges na Walda na Socket: Ana yin amfani da flanges masu kama da zamewa, flanges na walda na socket don daidaita ramukan girman bututu, wanda ke ba da damar walda na fillet a gefen baya don ɗaure haɗin. Yawanci ana amfani da su ga ƙananan bututun rami.

● Flanges Masu Makanta: Waɗannan flanges ba su da ramin tsakiya kuma ana amfani da su don rufe ko toshe ƙarshen tsarin bututu.

Waɗannan su ne wasu daga cikin nau'ikan flanges ɗin bututu da aka saba amfani da su a aikace-aikace daban-daban na masana'antu da kasuwanci. Zaɓin nau'in flanges ya dogara ne akan abubuwa kamar matsin lamba, zafin jiki, da nau'in ruwan da ake jigilarwa, da kuma takamaiman buƙatun aikin. Zaɓi da shigar da flanges masu kyau suna da mahimmanci don aminci da ingantaccen aiki na tsarin bututu.

Bayani dalla-dalla

| ASME B16.5: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

| EN 1092-1: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Kauri |

| DIN 2501: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

| GOST 33259: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Kauri |

| SABS 1123: Karfe Mai Kauri, Bakin Karfe, Karfe Mai Alloy |

Kayan Flange

Ana haɗa flanges ɗin da bututu da bututun ƙarfe. Saboda haka, ana ƙera shi ne daga waɗannan kayan;

● Karfe mai amfani da carbon

● Ƙaramin ƙarfe mai ƙarfe

● Bakin ƙarfe

● Haɗakar kayan waje (Stub) da sauran kayan tallafi

Jerin kayan da ake amfani da su a masana'antu an rufe su a cikin ASME B16.5 & B16.47.

● ASME B16.5 - Bututun Flanges da Flanges NPS ½" zuwa 24"

● ASME B16.47 - Manyan Faɗin Karfe NPS 26" zuwa 60"

Abubuwan da aka fi amfani da su sune kayan da aka ƙera

● Karfe Mai Kauri: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Karfe Mai Alloy: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Bakin Karfe: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Girman Flange na Zamewa na Aji 150

| Girman Inci | Girman a mm | Dia na waje. | Flange Mai Kauri. | Cibiyar OD | Tsawon Flange | RF Dia. | Tsayin RF | PCD | Soket Bore | Adadin Bolts | Girman Bolt UNC | Tsawon Kulle na Inji | Tsawon Ingarma na RF | Girman rami | Girman Ingarma na ISO | Nauyi a cikin kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Girman flange na wuyan walda na aji 150

| Girman Inci | Girman a mm | Diamita na waje | Kauri na Flange | Cibiyar OD | Wuyan Weld OD | Tsawon Wuyan Walda | Bore | Diamita na RF | Tsayin RF | PCD | Fuskar Walda |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Welding Wuya ramin wuya ya samo asali ne daga jadawalin bututu | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Girman Flange na Makafi na Aji 150

| Girman | Girman | Waje | Flange | RF | RF | PCD | Adadin | Girman Bolt | Ƙofar Inji | RF Ingarma | Girman rami | ISO Stud | Nauyi |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Daidaitacce & Matsayi

| ASME B16.5: Bututun Flanges da Kayan Aiki Masu Lanƙwasa | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| EN 1092-1: Flanges da Haɗinsu - Flanges na Zagaye don Bututu, Bawuloli, Kayan Aiki, da Kayan Haɗi, An ƙayyade PN - Kashi na 1: Flanges na Karfe | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe

|

| DIN 2501: Flanges da Haɗin gwiwa da aka Lapse | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| GOST 33259: Flanges don bawuloli, kayan aiki, da bututun mai don matsa lamba zuwa PN 250 | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

| SABS 1123: Flanges na Bututu, Bawuloli, da Kayan Aiki | Kayan Aiki: Karfe Mai Ƙarfe, Bakin Karfe, Karfe Mai Ƙarfe Mai Ƙarfe |

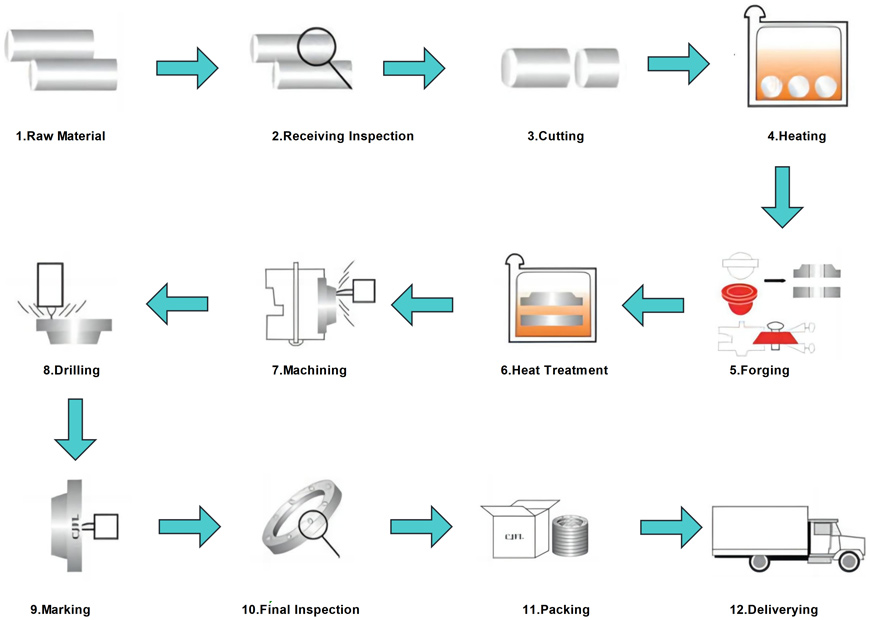

Tsarin Masana'antu

Sarrafa Inganci

Duba Kayan Danye, Binciken Sinadarai, Gwajin Inji, Duba Gani, Duba Girma, Gwajin Lanƙwasa, Gwajin Faɗi, Gwajin Tasiri, Gwajin DWT, Gwajin Ba Mai Lalacewa Ba (UT, MT, PT, X-Ray,), Gwajin Tauri, Gwajin Matsi, Gwajin Zubar da Kujeru, Gwajin Ƙarfe, Gwajin Tsatsa, Gwajin Juriyar Wuta, Gwajin Fesa Gishiri, Gwajin Aikin Gudawa, Gwajin Ƙarfi da Tuƙa, Zane da Duba Shafi, Bitar Takardu…..

Amfani & Aikace-aikace

Flanges muhimman sassan masana'antu ne da ake amfani da su wajen haɗa bututu, bawuloli, kayan aiki da sauran sassan bututu. Suna taka muhimmiyar rawa wajen haɗawa, tallafawa da rufe tsarin bututu. Flanges suna aiki a matsayin muhimman abubuwa a aikace-aikace daban-daban na masana'antu, ciki har da:

● Tsarin Bututu

● Bawuloli

● Kayan aiki

● Haɗi

● Rufewa

● Gudanar da Matsi

Shiryawa & Jigilar Kaya

A Womic Steel, mun fahimci mahimmancin marufi mai aminci da jigilar kaya mai inganci idan ana maganar isar da kayan aikin bututunmu masu inganci zuwa ƙofar gidanku. Ga taƙaitaccen bayani game da hanyoyin marufi da jigilar kaya don amfaninku:

Marufi:

An shirya bututunmu da kyau don tabbatar da cewa sun isa gare ku cikin kyakkyawan yanayi, a shirye don buƙatunku na masana'antu ko kasuwanci. Tsarin marufi namu ya haɗa da waɗannan mahimman matakai:

● Duba Inganci: Kafin a rufe dukkan flanges, ana duba inganci sosai don tabbatar da cewa sun cika ƙa'idodinmu masu tsauri don aiki da inganci.

● Rufin Kariya: Dangane da nau'in kayan da aka yi amfani da su, flanges ɗinmu na iya samun murfin kariya don hana tsatsa da lalacewa yayin jigilar kaya.

● Haɗawa Mai Tsaro: Ana haɗa flanges ɗin tare lafiya, don tabbatar da cewa sun kasance masu karko kuma an kare su a duk lokacin jigilar kaya.

● Lakabi da Takardu: Kowace fakiti an yi mata lakabi da muhimman bayanai, gami da ƙayyadaddun bayanai na samfura, adadi, da duk wani umarni na musamman na sarrafa su. Takardu masu dacewa, kamar takaddun shaida na bin ƙa'ida, suma an haɗa su.

● Marufi na Musamman: Za mu iya ɗaukar buƙatun marufi na musamman bisa ga buƙatunku na musamman, tare da tabbatar da cewa an shirya flanges ɗinku daidai yadda ake buƙata.

Jigilar kaya:

Muna haɗin gwiwa da abokan hulɗar jigilar kaya masu daraja don tabbatar da isar da kaya mai inganci da kan lokaci zuwa wurin da kuka ƙayyade. Ƙungiyar jigilar kayayyaki tamu tana inganta hanyoyin jigilar kaya don rage lokutan jigilar kaya da rage haɗarin jinkiri. Ga jigilar kaya ta ƙasashen waje, muna kula da duk takaddun kwastam da suka wajaba da bin ƙa'idodi don sauƙaƙe share kwastam cikin sauƙi. Muna ba da zaɓuɓɓukan jigilar kaya masu sassauƙa, gami da jigilar kaya cikin sauri don buƙatun gaggawa.