Bayanin Samfurin

Bututun ƙarfe na LSAW (Lingitudinal Submerged Arc Welding) nau'in bututun ƙarfe ne da aka haɗa da tsarin kera su na musamman da kuma nau'ikan aikace-aikace iri-iri. Ana ƙera waɗannan bututun ta hanyar ƙirƙirar farantin ƙarfe zuwa siffar silinda da kuma haɗa shi ta hanyar amfani da dabarun walda na baka. Ga taƙaitaccen bayani game da bututun ƙarfe na LSAW:

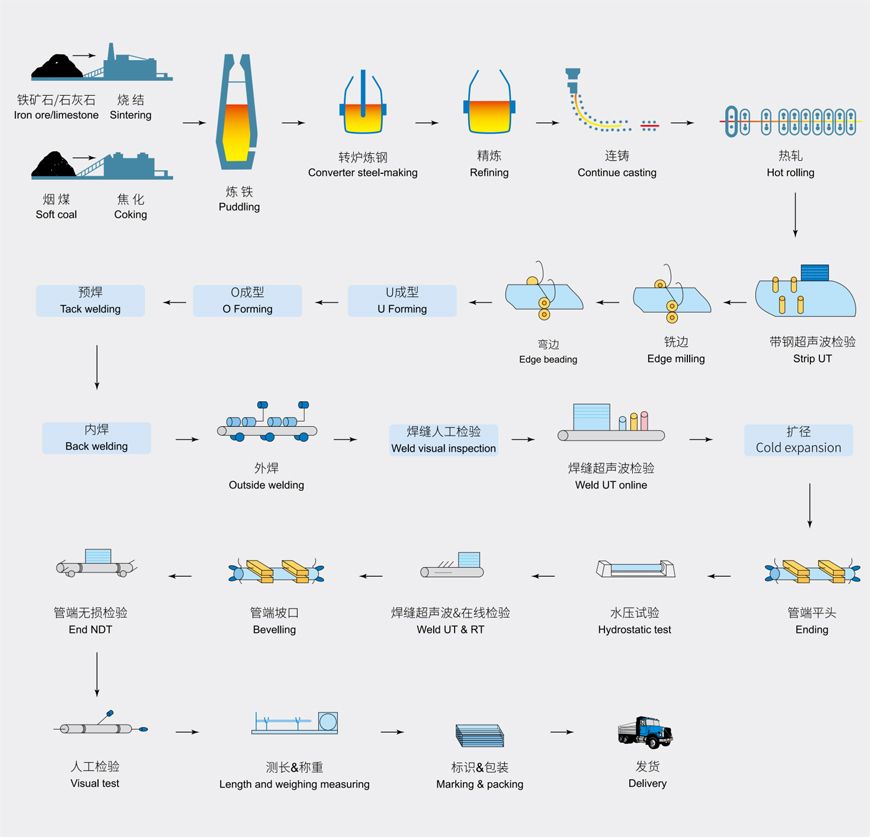

Tsarin Masana'antu:

● Shirya Faranti: Ana zaɓar faranti masu inganci bisa ga takamaiman buƙatu, wanda ke tabbatar da halayen injina da kuma sinadaran da ake buƙata.

● Samarwa: Ana siffanta farantin ƙarfe zuwa bututu mai siffar silinda ta hanyar hanyoyin kamar lanƙwasawa, birgima, ko matsi (JCOE da UOE). An riga an lanƙwasa gefuna don sauƙaƙe walda.

● Walda: Ana amfani da walda mai zurfi a ƙarƙashin ruwa (SAW), inda ake kiyaye baka a ƙarƙashin wani yanki mai kwarara. Wannan yana samar da walda masu inganci tare da ƙarancin lahani da haɗuwa mai kyau.

● Dubawar Ultrasonic: Bayan walda, ana yin gwajin ultrasonic don gano duk wani lahani na ciki ko na waje a yankin walda.

● Faɗaɗawa: Ana iya faɗaɗa bututun don cimma diamita da kauri da ake so na bango, wanda ke ƙara daidaiton girma.

● Dubawa ta Ƙarshe: Gwaji mai zurfi, gami da duba gani, duba girma, da gwaje-gwajen halayen injina, yana tabbatar da ingancin bututun.

Fa'idodi:

● Ingantaccen Kuɗi: Bututun LSAW suna ba da mafita mai inganci ga bututun mai girman diamita da aikace-aikacen tsari saboda ingantaccen tsarin kera su.

● Babban Ƙarfi: Hanyar walda mai tsayi tana haifar da bututu masu ƙarfi da daidaiton kayan aiki.

● Daidaito Mai Girma: Bututun LSAW suna nuna daidaito, wanda hakan ya sa suka dace da amfani da su tare da juriya mai tsauri.

● Ingancin Walda: Walda mai zurfi a cikin ruwa tana samar da walda masu inganci tare da haɗakarwa mai kyau da ƙarancin lahani.

● Sauƙin Amfani: Ana amfani da bututun LSAW a masana'antu daban-daban, ciki har da mai da iskar gas, gini, da samar da ruwa, saboda sauƙin daidaitawa da dorewarsu.

A taƙaice, ana ƙera bututun ƙarfe na LSAW ta amfani da tsari mai inganci da inganci, wanda ke haifar da amfani da bututu masu araha, masu araha, kuma masu ɗorewa waɗanda suka dace da aikace-aikacen masana'antu iri-iri.

Bayani dalla-dalla

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Daraja C250, Daraja C350, Daraja C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

Nisa Tsakanin Samarwa

| Diamita na Waje | Kauri na bango da ake da shi don ƙasa da matakin ƙarfe | |||||||

| Inci | mm | Karfe Grade | ||||||

| Inci | mm | L245(Gr.B) | L290(X42) | L360(X52) | L415(X60) | L450(X65) | L485(X70) | L555(X80) |

| 16 | 406 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 18 | 457 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 20 | 508 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 22 | 559 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 24 | 610 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 26 | 660 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 28 | 711 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 30 | 762 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 32 | 813 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 34 | 864 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 36 | 914 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 38 | 965 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 40 | 1016 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 42 | 1067 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 44 | 1118 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 46 | 1168 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 48 | 1219 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 52 | 1321 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 56 | 1422 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 60 | 1524 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 64 | 1626 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 68 | 1727 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 72 | 1829 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

* Ana iya keɓance sauran Girman bayan tattaunawa

Sinadaran Sinadarai da Kayayyakin Inji na Bututun Karfe na LSAW

| Daidaitacce | Matsayi | Sinadaran da Aka Haɗa (max)% | Kayayyakin Inji (minti) | |||||

| C | Mn | Si | S | P | Ƙarfin Yawa (Mpa) | Ƙarfin Tashin Hankali (Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Daidaitacce & Matsayi

| Daidaitacce | Karfe maki |

| API 5L: Bayani dalla-dalla game da Bututun Layi | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Takamaiman Bayani na Musamman don Tubalan Bututun Karfe Masu Walda da Mara Sumul | GR.1, GR.2, GR.3 |

| EN 10219-1: Sassan ƙarfe marasa ƙarfe da ƙananan hatsi da aka haɗa da tsarin walda mai sanyi | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Sassan Tsarin Gine-gine Masu Zafi Na Karfe Marasa Alloy da Kyawawan Hatsi | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Bututu, Karfe, Baƙi da kuma ruwan zafi, An rufe shi da Zinc, An haɗa shi da walda kuma ba shi da sumul | GR.A, GR.B |

| EN 10208: Bututun ƙarfe don amfani a cikin tsarin jigilar bututun mai a masana'antar mai da iskar gas. | L210GA, L235GA, L245GA, L290GA, L360GA |

| EN 10217: Bututun ƙarfe da aka haɗa da walda don dalilai na matsi | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Bututun ƙarfe da bututun da aka haɗa da walda | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Ma'aunin Australiya/New Zealand don Sassan Karfe Masu Sanyi da Aka Yi da Sanyi | Darasi C250, Darasi C350, Darasi C450 |

| GB/T 9711: Masana'antar Man Fetur da Iskar Gas - Bututun Karfe don Bututun | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| ASTM A671: Bututun Karfe Mai Haɗa Wutar Lantarki Don Yanayin Yanayi da Ƙananan Zafi | CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70 |

| ASTM A672: Bututun ƙarfe mai haɗa wutar lantarki da walda don yin aiki mai ƙarfi a yanayin zafi mai matsakaici. | A45, A50, A55, B60, B65, B70, C55, C60, C65 |

| ASTM A691: Bututun ƙarfe na carbon da ƙarfe mai ƙarfe, an haɗa shi da walda ta lantarki don yin aiki mai ƙarfi a yanayin zafi mai yawa. | CM-65, CM-70, CM-75, 1/2CR-1/2MO, 1CR-1/2MO, 2-1/4CR, 3CR |

Tsarin Masana'antu

Sarrafa Inganci

● Duba Kayan Danye

● Nazarin Sinadarai

● Gwajin Inji

● Duban Gani

● Duba Girma

● Gwajin Lanƙwasa

● Gwajin Tasiri

● Gwajin Tsatsa Tsakanin Granular

● Jarrabawar da ba ta lalata jiki ba (UT, MT, PT)

● Cancantar Tsarin Walda

● Binciken Tsarin Ƙananan Sifofi

● Gwajin Faɗaɗawa da Faɗaɗawa

● Gwajin Tauri

● Gwajin Hydrostatic

● Gwajin Nazarin Ƙarfe

● Gwajin Tsagaita Wutar Lantarki Mai Haɗarin Hydrogen (HIC)

● Gwajin Tsagaita Damuwar Sulfide (SSC)

● Gwajin Eddy na Yanzu

● Duba Zane da Rufi

● Bitar Takardu

Amfani & Aikace-aikace

Bututun ƙarfe na LSAW (Longitudinal Submerged Arc Welding) suna samun aikace-aikace iri-iri a fannoni daban-daban saboda ingancin tsarinsu da kuma sauƙin amfani da su. Ga wasu daga cikin mahimman amfani da aikace-aikacen bututun ƙarfe na LSAW:

● Sufurin Mai da Iskar Gas: Ana amfani da bututun ƙarfe na LSAW sosai a masana'antar mai da iskar gas don tsarin bututun. Ana amfani da waɗannan bututun don jigilar ɗanyen mai, iskar gas, da sauran ruwaye ko iskar gas.

● Kayayyakin Ruwa: Ana amfani da bututun LSAW a ayyukan samar da ababen more rayuwa da suka shafi ruwa, gami da tsarin samar da ruwa da magudanar ruwa.

● Sarrafa Sinadarai: Bututun LSAW suna aiki a masana'antun sinadarai inda ake amfani da su don isar da sinadarai, ruwa, da iskar gas cikin aminci da inganci.

● Gine-gine da Kayayyakin more rayuwa: Ana amfani da waɗannan bututun a ayyukan gini daban-daban, kamar ginin tushe, gadoji, da sauran aikace-aikacen gini.

● Tuba: Ana amfani da bututun LSAW wajen tattarawa don samar da tallafi na asali a ayyukan gini, gami da harsashin gini da gine-ginen ruwa.

● Sashen Makamashi: Ana amfani da su wajen jigilar nau'ikan makamashi daban-daban, gami da tururi da ruwan zafi a cikin tashoshin samar da wutar lantarki.

● Haƙar ma'adinai: Bututun LSAW suna samun amfani a ayyukan haƙar ma'adinai don jigilar kayayyaki da wutsiya.

● Tsarin Masana'antu: Masana'antu kamar masana'antu da samarwa suna amfani da bututun LSAW don hanyoyin masana'antu daban-daban, gami da jigilar kayan aiki da kayayyakin da aka gama.

● Ci Gaban Kayayyakin more rayuwa: Waɗannan bututun suna da matuƙar muhimmanci wajen haɓaka ayyukan samar da ababen more rayuwa kamar hanyoyi, manyan hanyoyi, da kuma ayyukan samar da wutar lantarki a ƙarƙashin ƙasa.

● Tallafin Gine-gine: Ana amfani da bututun LSAW don ƙera tallafi na tsari, ginshiƙai, da katako a ayyukan gini da injiniya.

● Gina Jiragen Ruwa: A masana'antar gina jiragen ruwa, ana amfani da bututun LSAW don gina sassa daban-daban na jiragen ruwa, gami da ginshiƙai da sassan gini.

● Masana'antar Motoci: Ana iya amfani da bututun LSAW wajen kera kayan aikin mota, gami da tsarin fitar da hayaki.

Waɗannan aikace-aikacen suna nuna sauƙin amfani da bututun ƙarfe na LSAW a sassa daban-daban, saboda dorewarsu, ƙarfinsu, da kuma dacewa da yanayi daban-daban na muhalli.

Shiryawa & Jigilar Kaya

Ingantaccen tattarawa da jigilar bututun ƙarfe na LSAW (Longitudinal Submerged Arc Welding) suna da matuƙar muhimmanci don tabbatar da jigilar su lafiya da isar da su zuwa wurare daban-daban. Ga bayanin hanyoyin tattarawa da jigilar su na yau da kullun don bututun ƙarfe na LSAW:

Shiryawa:

● Haɗa bututun LSAW: Sau da yawa ana haɗa bututun LSAW tare ko kuma a haɗa su da madauri ɗaya ta amfani da madauri na ƙarfe ko madauri don ƙirƙirar na'urori masu sauƙin sarrafawa don sarrafawa da jigilar su.

● Kariya: Ana kare ƙarshen bututu da murfi na filastik don hana lalacewa yayin jigilar kaya. Bugu da ƙari, ana iya rufe bututun da kayan kariya don kariya daga abubuwan da ke haifar da muhalli.

● Rufin Hana Tsatsa: Idan bututun suna da rufin hana tsatsa, ana tabbatar da ingancin murfin yayin tattarawa don hana lalacewa yayin sarrafawa da jigilar kaya.

● Alamar da Lakabi: Kowace fakiti an yi mata lakabi da muhimman bayanai kamar girman bututu, matakin kayan aiki, lambar zafi, da sauran bayanai don sauƙin ganewa.

● Tsarewa: Ana ɗaure fakitin da kyau a kan fale-falen kaya ko skid don hana motsi yayin jigilar kaya.

Jigilar kaya:

● Yanayin Sufuri: Ana iya jigilar bututun ƙarfe na LSAW ta amfani da hanyoyi daban-daban na sufuri, gami da hanya, layin dogo, teku, ko iska, ya danganta da inda ake zuwa da kuma gaggawar da ake buƙata.

● Sanya bututu a cikin kwantena: Ana iya jigilar bututu a cikin kwantena don ƙarin kariya, musamman a lokacin jigilar kaya zuwa ƙasashen waje. Ana ɗora kwantena kuma ana ɗaure su don hana canzawa yayin jigilar kaya.

● Abokan Hulɗa da Sufuri: Kamfanonin jigilar kayayyaki masu suna ko kuma masu ɗaukar kaya waɗanda suka ƙware a sarrafa bututun ƙarfe suna aiki don tabbatar da isar da kayayyaki cikin aminci da kuma kan lokaci.

● Takardun Kwastam: Ana shirya takardun kwastam da ake buƙata, gami da takardun jigilar kaya, takaddun asali, da sauran takardu masu dacewa, kuma ana gabatar da su don jigilar kaya daga ƙasashen waje.

● Inshora: Dangane da darajar da yanayin kayan, ana iya shirya inshora don kare kai daga abubuwan da ba a zata ba yayin jigilar kaya.

● Bin diddigi: Tsarin bin diddigi na zamani yana bawa mai aikawa da mai karɓa damar bin diddigin ci gaban jigilar kaya a ainihin lokaci, yana tabbatar da bayyana gaskiya da sabuntawa akan lokaci.

● Isarwa: Ana sauke bututu a inda za a kai su, ta hanyar bin hanyoyin da suka dace na sauke kaya don guje wa lalacewa.

● Dubawa: Da isowa, ana iya duba bututun don tabbatar da yanayinsu da kuma yadda suka dace da ƙa'idodi kafin a karɓe su daga mai karɓa.

Tsarin tattarawa da jigilar kaya yadda ya kamata yana taimakawa wajen hana lalacewa, kiyaye ingancin bututun ƙarfe na LSAW, da kuma tabbatar da cewa sun isa inda aka nufa lafiya kuma cikin yanayi mai kyau.