Bututu bisa ga amfani da kayan bututu, hanyoyin haɗin da aka saba amfani da su sune: haɗin zare, haɗin flange, walda, haɗin tsagi (haɗin manne), haɗin ferrule, haɗin matsi na kati, haɗin narke mai zafi, haɗin soket da sauransu.

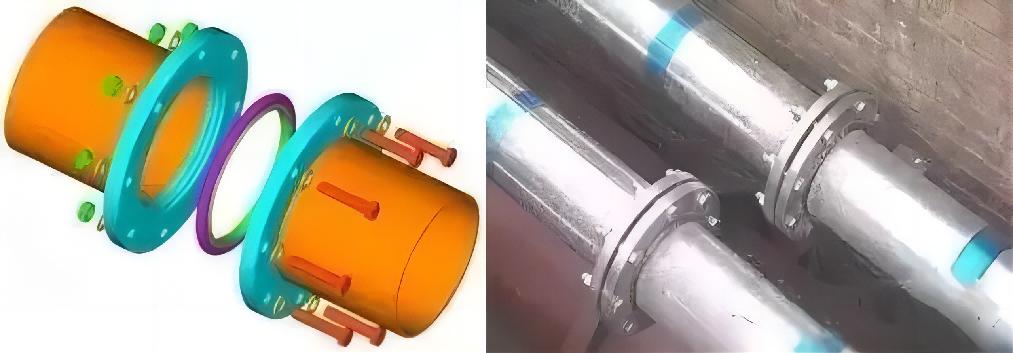

1. Haɗin Flange

Ana haɗa manyan bututun diamita ta hanyar flanges, kuma galibi ana amfani da haɗin flanges a cikin manyan bawuloli na haɗi, bawuloli na duba, mitar ruwa, famfo, da sauransu, da kuma buƙatar wargajewa akai-akai da kuma kula da sashin bututun. Bututun galvanized kamar walda ko haɗin flanges, walda ya kamata ya zama na biyu na galvanized ko tsatsa.

2. Walda

Walda ta shafi bututun ƙarfe mara galvanized, galibi ana amfani da shi don bututun da aka ɓoye da kuma bututun diamita mafi girma, da kuma ƙarin aikace-aikace a cikin gine-gine masu tsayi. Haɗin bututun tagulla zai iya amfani da haɗin gwiwa na musamman ko walda, lokacin da diamita na bututun bai wuce ramin 22mm ba ko walda ta dace, soket ya kamata ya dace da alkiblar kwararar kafofin watsa labarai, lokacin da diamita na bututun ya fi ko daidai da 22mm ya dace don amfani da walda ta butt. Bututun bakin ƙarfe na iya zama walda ta soket.

3. Haɗin Sukuri

Haɗin zare shine amfani da kayan haɗin bututu tare da haɗin zare, diamita na bututu ƙasa da ko daidai da 100mm na bututun ƙarfe na galvanized ya kamata a haɗa shi da zare, galibi ana amfani da shi don buɗe bututu. Ana amfani da bututun haɗa ƙarfe da filastik gabaɗaya. Ya kamata a haɗa bututun ƙarfe na galvanized, saitin maƙallin siliki lokacin da ya kamata a lalata saman Layer na galvanized da ɓangaren zare da aka fallasa don hana tsatsa; ya kamata a yi amfani da shi don kayan haɗin musamman na flange ko ferrule don haɗa bututun ƙarfe na galvanized kuma flange na walda ya kamata a haɗa shi da zare a karo na biyu.

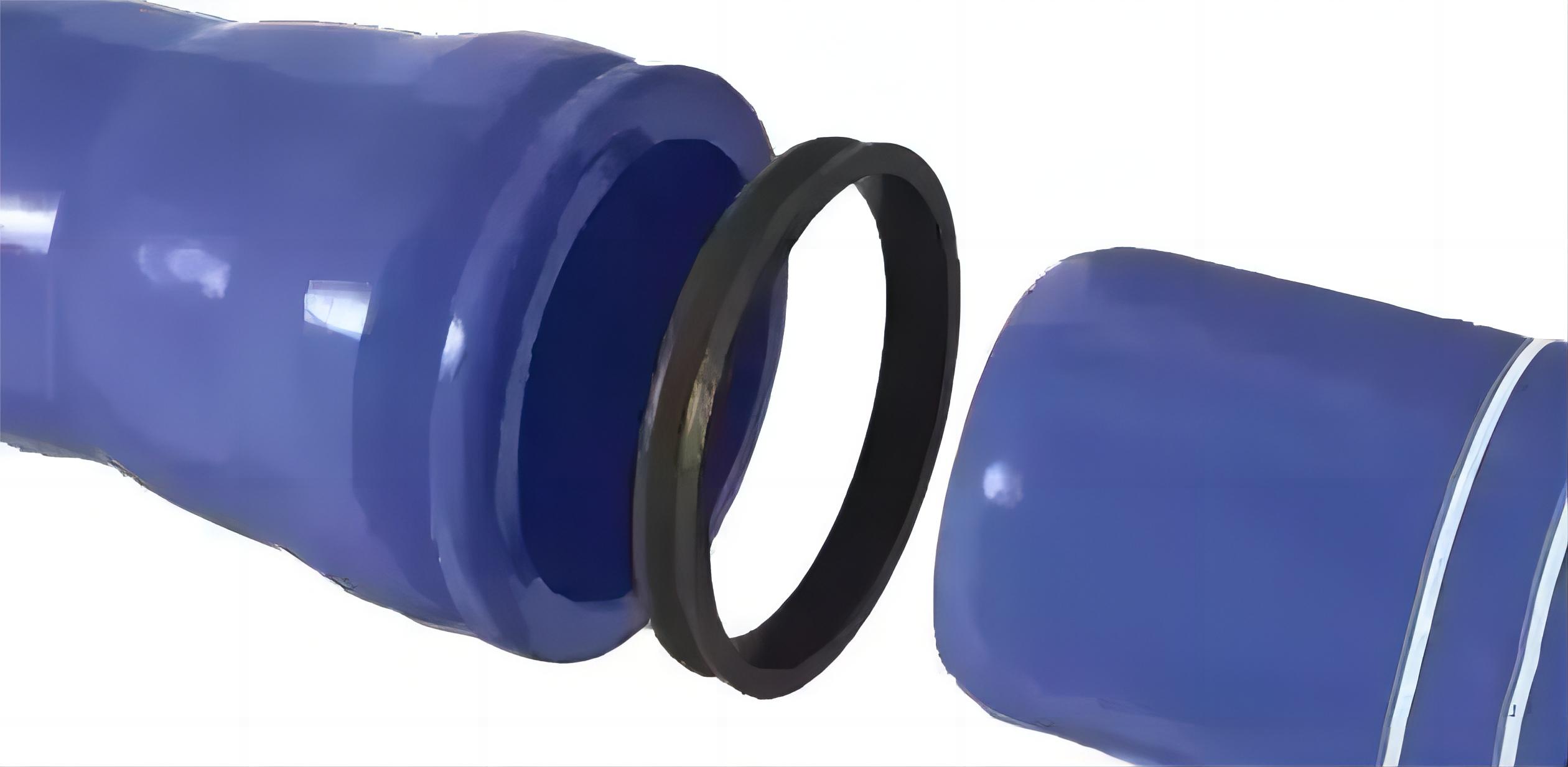

4. Haɗin Socket

Ana amfani da shi don haɗa bututun ƙarfe da bututun ruwa. Akwai nau'ikan haɗin gwiwa masu sassauƙa guda biyu da haɗin gwiwa masu tauri, haɗin gwiwa masu sassauƙa ana rufe su da zoben roba, haɗin gwiwa masu tauri ana rufe su da simintin asbestos ko kuma abubuwan cikawa masu faɗi, kuma hatimin gubar suna samuwa don muhimman lokatai.

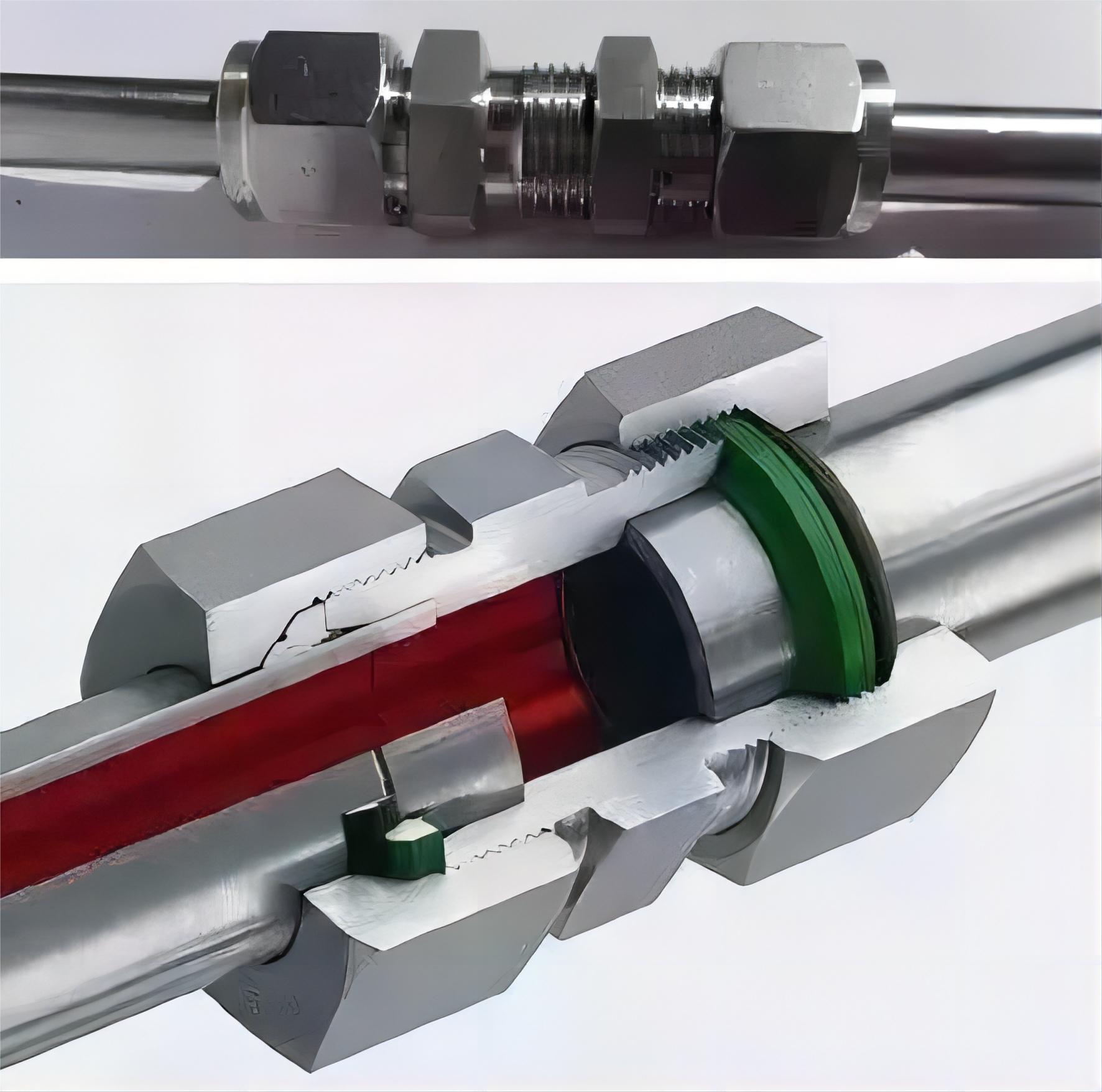

5.FerruleChaɗin kai

Bututun da aka haɗa da aluminum da filastik galibi ana yi musu kauri da ferrules masu zare. Ana sanya goro a ƙarshen bututun, sannan a sanya core ɗin kayan a ƙarshen, tare da maƙulli don matse kayan da goro. Hakanan ana iya amfani da haɗin bututun tagulla mai zare.

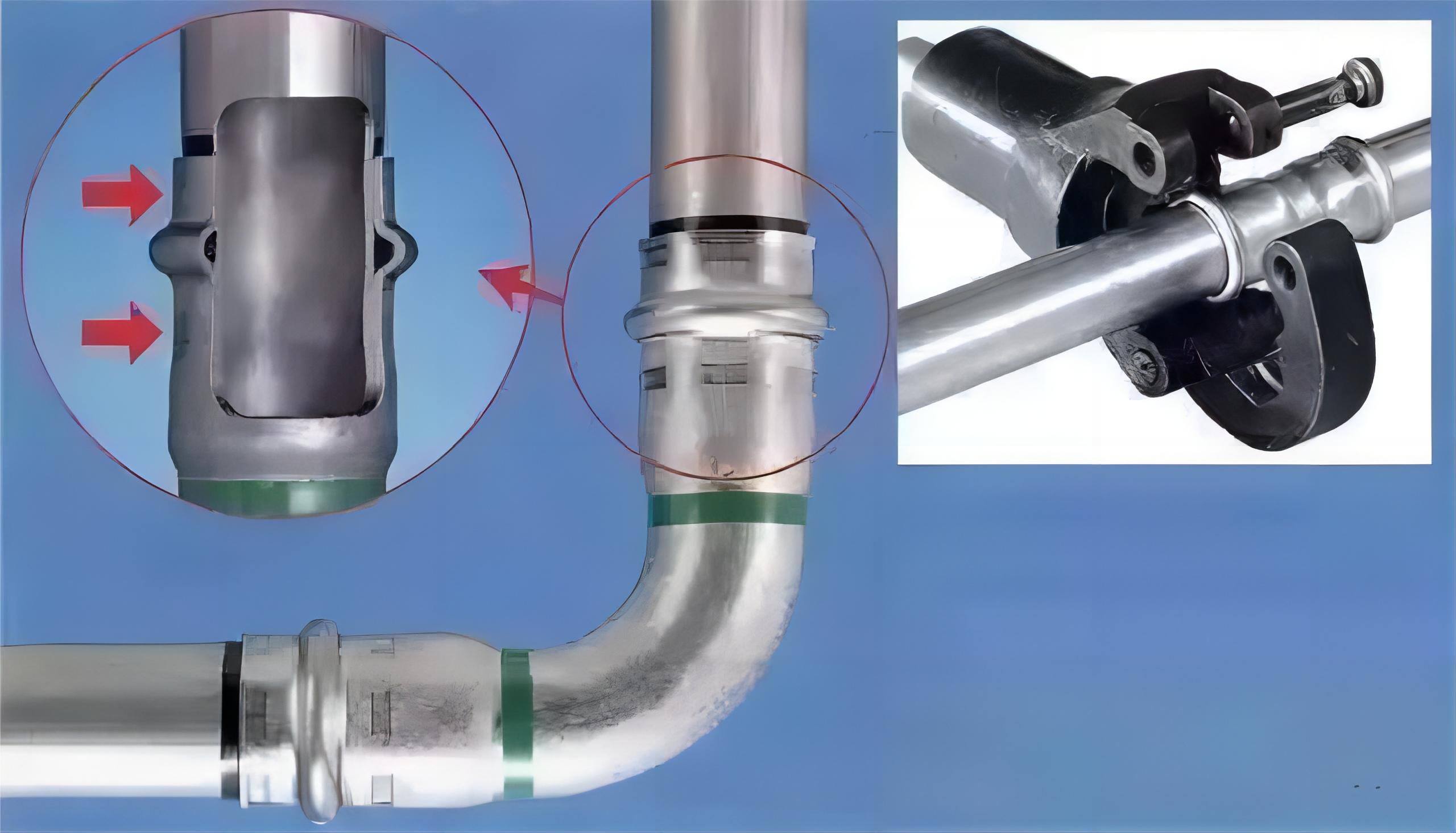

6. Haɗin Manne

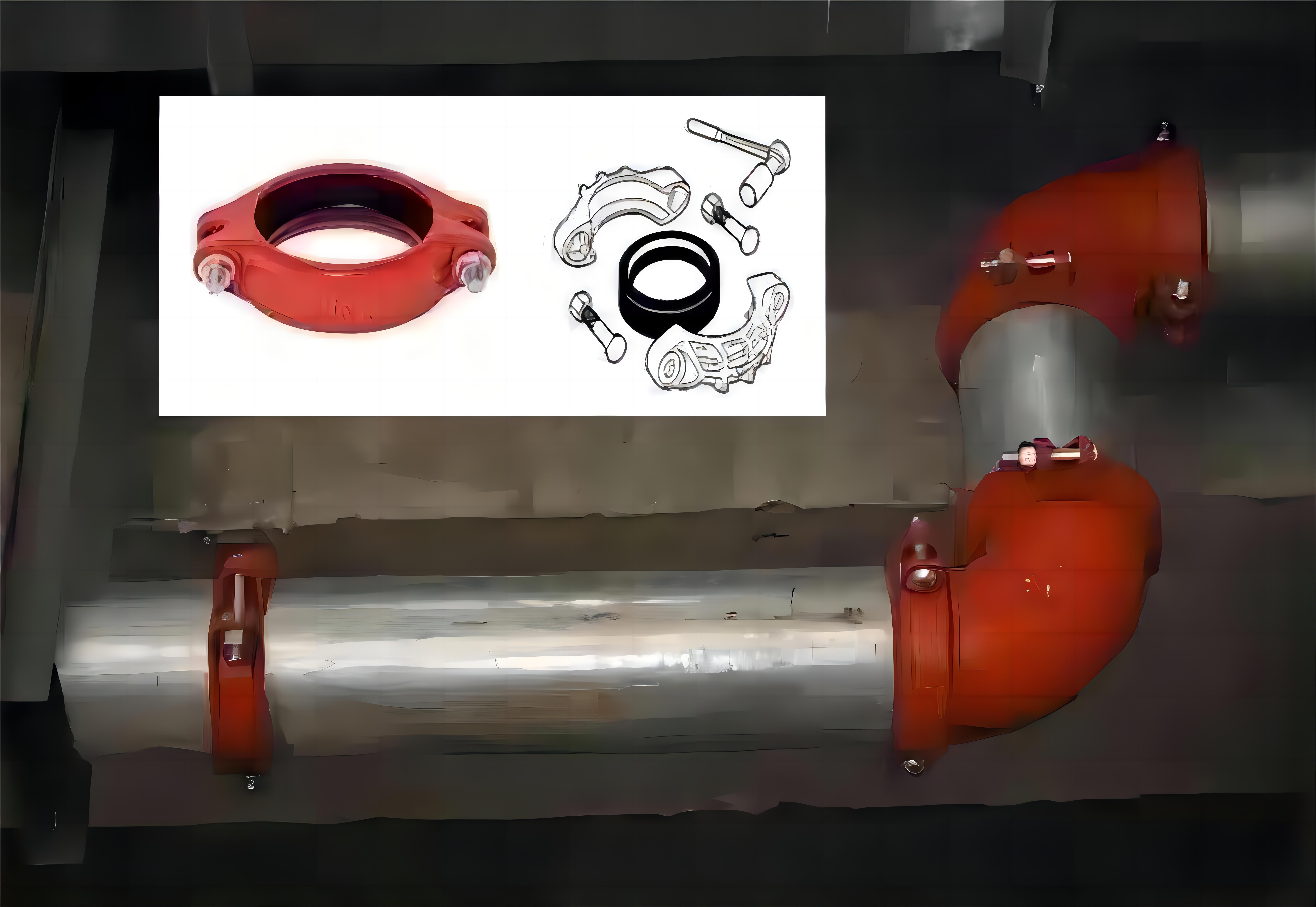

Fasahar haɗa kayan haɗin bakin ƙarfe don maye gurbin zare, walda, manne da sauran fasahar haɗin bututun samar da ruwa na gargajiya, tare da kariyar tsaftar ruwa, juriya ga tsatsa, tsawon rai da sauransu, gina zoben rufewa na musamman tare da kayan haɗin soket na musamman da haɗin bututun, amfani da kayan aiki na musamman don matse bakin bututun don yin tasirin rufewa da matsewa, gina shigarwar yana da dacewa, abin dogaro kuma mai ma'ana a fannin tattalin arziki da sauran fa'idodi.

7. Haɗin Hotmelt

Hanyar haɗin bututun PPR ita ce haɗin haɗin zafi ta hanyar na'urar haɗa zafi.

8. Haɗa Groove

Lokacin Saƙo: Nuwamba-06-2023