Gabatarwa:

API 5L wani tsari ne na musamman da Cibiyar Man Fetur ta Amurka (API) ta kafa don bututun ƙarfe marasa sulke da walda da ake amfani da su a tsarin sufuri a cikin masana'antar mai da iskar gas. Womic Steel, babbar masana'antar bututun layin API 5L, tana ba da cikakken kewayon samfura waɗanda suka dace da matakai da ƙayyadaddun bayanai daban-daban. Wannan labarin yana ba da cikakken kwatancen abubuwan da ke cikin sinadarai, halayen injiniya, da ƙa'idodin gwaji don nau'ikan API 5L daban-daban, duka PSL1 da PSL2 a cikin nau'ikan bututu guda uku: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), da SMLS (Seamless).

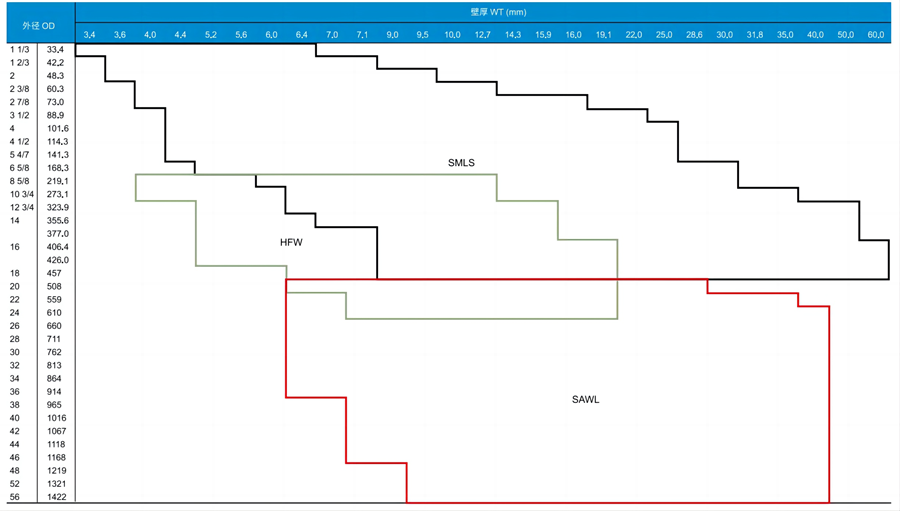

Ƙarfin Samarwa da Kewaya:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Minti mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMSS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Juriyar Diamita ta Waje

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| Takamaiman API SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ±2.0mm | ±1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Lura: D shine diamita na waje na bututun.

Juriyar Kauri a Bango

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| Takamaiman API ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst <25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t <30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t <37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

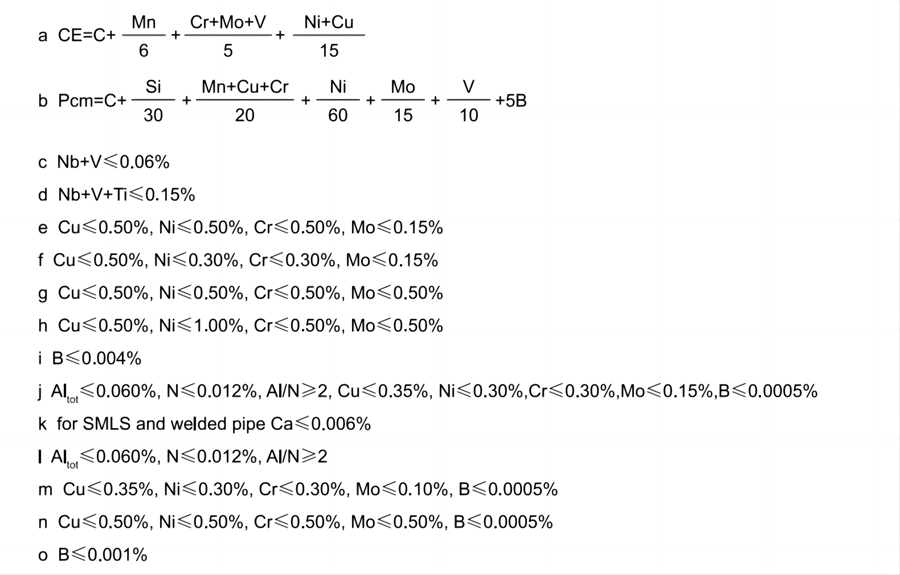

Binciken Sinadarai

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Kwamfuta mai kwakwalwa (pcm) | 备注 |

| matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | |||||

| API TAMBAYOYI 5L | 无缝管 | PSL1 | L210 ko A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 ko B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 ko X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 ko X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 ko X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 ko X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 ko X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 ko X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| daga,o | |||

| L485 ko X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N ko BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N ko X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N ko X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N ko X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N ko X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N ko X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Kamar yadda aka amince | d,g,o | ||||

| L245Q ko BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q ko X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q ko X46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 ko × 52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q ya da X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q ya da X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q ya da X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q ko X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q ya da X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Kamar yadda aka amince | h,i | ||||

| 酸性服 | L245NS ko BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS ko X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS ko X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS ko X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS ko BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS ya da X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS ya da X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS ya da X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS ya da X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS ya da X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS ya da X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS ya da X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Kwamfuta mai kwakwalwa (pcm) | 备注 |

| matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO ko BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,ni,m |

| L290NO ko X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO ko X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d,ni,m | |||

| L360NO ko X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,ni | |||

| L245QO ko BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO ko X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO ko X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO ko X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,ni,n | |||

| L390QO ko X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,ni,n | |||

| L415QO ya da X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,ni,n | |||

| L455QO ko X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,ni,n | |||

| L485Q0 ko X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO ya da X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Kamar yadda aka amince | d,ni,n | ||||

| 焊管 | PSL1 | L245 ko B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 koX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 koX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 ko X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 koX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 koX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 ko X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 ko X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M ko BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M ko X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M ko X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M ko X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M ko X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M ko X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M ko X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M ko X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M ko X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Kwamfuta mai kwakwalwa (pcm) | 备注 |

| matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | matsakaicin | |||||

| API TAMBAYOYI 5L | 焊管 | 酸性服 | L245MS ko BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS ko X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS ko X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS ko X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS ko X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS ko X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS ko X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS ko X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO ko BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO ko X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO ko X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Ni, ni | |||

| L360MO ko X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,ni,n | |||

| L390MO ko X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO ko X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,ni,n | |||

| L450MO ko X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,ni,n | |||

| L485MO ko X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO ko X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,ni,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API TAMBAYOYI 5L | PSL1 | L210 ko A | Minti | 210 | 335 | a |

| 335 |

| L245 ko B | Minti | 245 | 415 | a |

| 415 | ||

| L290 ko X42 | Minti | 290 | 415 | a |

| 415 | ||

| L320 ko X46 | Minti | 320 | 435 | a |

| 435 | ||

| L360 ko X52 | Minti | 360 | 460 | a |

| 460 | ||

| L390 ko X56 | Minti | 390 | 490 | a |

| 490 | ||

| L415 ko X60 | Minti | 415 | 520 | a |

| 520 | ||

| L450 ko X65 | Minti | 450 | 535 | a |

| 535 | ||

| L485 ko X70 | Minti | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N ko BN | Minti | 245 | 415 | a |

| 415 | |

| Mafi girma | 450 | 655 |

| 0.93 |

| |||

| L290N ko X42N | Minti | 290 | 415 | a |

| 415 | ||

| Mafi girma | 495 | 655 |

| 0.93 |

| |||

| L320N ko X46N | Minti | 320 | 435 | a |

| 435 | ||

| Mafi girma | 525 | 655 |

| 0.93 |

| |||

| L360N ko X52N | Minti | 360 | 460 | a |

| 460 | ||

| Mafi girma | 530 | 760 |

| 0.93 |

| |||

| L390N ko X56N | Minti | 390 | 490 | a |

| 490 | ||

| Mafi girma | 545 | 760 |

| 0.93 |

| |||

| L415N ko X60N | Minti | 415 | 520 | a |

| 520 | ||

| Mafi girma | 565 | 760 |

| 0.93 |

| |||

| L450Q ya da X65Q | Minti | 450 | 535 | a |

| 535 | ||

| Mafi girma | 600 | 760 |

| 0.93 |

| |||

| L485Q ko X70Q | Minti | 485 | 570 | a |

| 570 | ||

| Mafi girma | 635 | 760 |

| 0.93 |

| |||

| L555Q ya da X80Q | Minti | 555 | 625 | a |

| 625 | ||

| Mafi girma | 705 | 825 |

| 0.93 |

| |||

| L625M ko X90M | Minti | 625 | 695 | a |

| 695 | ||

| Mafi girma | 775 | 915 |

| 0.95 |

| |||

| L690M ko X100M | Minti | 690 | 760 | a |

| 760 | ||

| Mafi girma | 840 | 990 |

| 0.97 |

| |||

| L830M ko X120M | Minti | 830 | 915 | a |

| 915 | ||

| Mafi girma | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API TAMBAYOYI 5L | 酸性服 | L245NS ko BNS | Minti | 245 | 415 | a |

| 415 |

| Mafi girma | 450 | 655 |

| 0.93 |

| |||

| L290NS ko X42NS | Minti | 290 | 415 | a |

| 415 | ||

| Mafi girma | 495 | 655 |

| 0.93 |

| |||

| L320NS ko X46NS | Minti | 320 | 435 | a |

| 435 | ||

| Mafi girma | 525 | 655 |

| 0.93 |

| |||

| L360NS ko X52NS | Minti | 360 | 460 | a |

| 460 | ||

| Mafi girma | 530 | 760 |

| 0.93 |

| |||

| L390QS ya da X56QS | Minti | 390 | 490 | a |

| 490 | ||

| Mafi girma | 545 | 760 |

| 0.93 |

| |||

| L415QS ya da X60QS | Minti | 415 | 520 | a |

| 520 | ||

| Mafi girma | 565 | 760 |

| 0.93 |

| |||

| L450QS ya da X65QS | Minti | 450 | 535 | a |

| 535 | ||

| Mafi girma | 600 | 760 |

| 0.93 |

| |||

| L485QS ya da X70QS | Minti | 485 | 570 | a |

| 570 | ||

| Mafi girma | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO ko BNO | Minti | 245 | 415 | a | - | 415 | |

| Mafi girma | 450 | 655 |

| 0.93 |

| |||

| L290NO ko X42NO | Minti | 290 | 415 | a |

| 415 | ||

| Mafi girma | 495 | 655 |

| 0.93 |

| |||

| L320NO ko X46NO | Minti | 320 | 435 | a |

| 435 | ||

| Mafi girma | 520 | 655 |

| 0.93 |

| |||

| L360NO ko X52NO | Minti | 360 | 460 | a |

| 460 | ||

| Mafi girma | 525 | 760 |

| 0.93 |

| |||

| L390QO ko X56QO | Minti | 390 | 490 | a |

| 490 | ||

| Mafi girma | 540 | 760 |

| 0.93 |

| |||

| L415QO ya da X60QO | Minti | 415 | 520 | a | - | 520 | ||

| Mafi girma | 565 | 760 |

| 0.93 |

| |||

| L450QO ko X65QO | Minti | 450 | 535 | a | - | 535 | ||

| Mafi girma | 570 | 760 |

| 0.93 |

| |||

| L485Q0 ko X70Q0 | Minti | 485 | 570 | a |

| 570 | ||

| Mafi girma | 605 | 760 |

| 0.93 |

| |||

| L555QO ya da X80QO | Minti | 555 | 625 | a |

| 625 | ||

| Mafi girma | 675 | 825 |

| 0.93 |

Lura: a: Mafi ƙarancin tsawaitawa ta amfani da lissafin da ke ƙasa: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 ko X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| > L415 ko X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 ko X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 ko X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Lura: (1) Ƙimar da ke cikin teburin sun dace da cikakken girman samfurin misali.

(2) Ƙimar da ke cikin maƙallin ita ce mafi ƙarancin ƙima ɗaya, maƙallin waje ita ce matsakaicin ƙima.

(3) Zafin Gwaji: 0°C.

Ma'aunin Gwaji:

Ana yin gwaje-gwaje masu tsauri don tabbatar da cewa bututun API 5L da Womic Steel ke ƙera sun cika mafi girman ƙa'idodi. Ka'idojin gwaji sun haɗa da:

Binciken Sinadarai:

Ana nazarin sinadaran da ke cikin ƙarfen don tabbatar da cewa ya cika buƙatun API 5L.

Ana gudanar da nazarin sinadarai ta amfani da na'urar auna bayanai kai tsaye don tantance daidaiton abubuwan da ke cikin ƙarfen.

Gwajin Inji:

Ana gwada kaddarorin injina kamar ƙarfin samarwa, ƙarfin tensile, da tsawo don tabbatar da cewa sun cika ƙa'idodin da aka ƙayyade.

Ana yin gwajin injina ta amfani da injin gwaji mai nauyin tan 60 don auna ƙarfi da juriyar ƙarfen.

Gwajin Hydrostatic:

Ana gudanar da gwajin hydrostatic don duba ingancin bututun da kuma tabbatar da cewa zai iya jure buƙatun matsin lamba na aikace-aikacen da aka yi niyya.

Ana cika bututun da ruwa kuma ana fuskantar matsin lamba, tare da tsawon lokacin gwajin da matakan matsin lamba da ƙa'idodin API 5L suka ƙayyade.

Gwajin da Ba Ya Lalacewa (NDT):

Ana amfani da hanyoyin NDT kamar gwajin ultrasonic (UT) da gwajin barbashi na maganadisu (MT) don gano duk wani lahani ko rashin daidaituwa a cikin bututun.

Ana amfani da UT don gano lahani na ciki, yayin da ake amfani da MT don gano lahani na saman.

Gwajin Tasiri:

Ana yin gwajin tasiri don tantance taurin ƙarfe a ƙananan yanayin zafi.

Ana amfani da gwajin tasirin Charpy akai-akai don auna kuzarin tasirin da ƙarfe ke sha.

Gwajin Tauri:

Ana gudanar da gwajin tauri don tantance taurin ƙarfe, wanda zai iya nuna ƙarfinsa da dacewarsa ga takamaiman aikace-aikace.

Ana amfani da gwajin taurin Rockwell sau da yawa don auna taurin ƙarfe.

Gwajin Tsarin Ƙananan Sifofi:

Ana gudanar da binciken ƙananan ƙwayoyin halitta don tantance tsarin hatsi da ingancin ƙarfe gaba ɗaya.

Ana amfani da na'urar hangen nesa ta ƙarfe don bincika tsarin ƙarfe da kuma gano duk wani lahani.

Ta hanyar bin waɗannan ƙa'idodin gwaji masu tsauri, Womic Steel ta tabbatar da cewa bututun layin API 5L ɗinta sun cika mafi girman buƙatun inganci kuma suna samar da ingantaccen aiki a aikace-aikacen masana'antu daban-daban.

Tsarin Samarwa:

1. Bututun Karfe Mara Sumul:

- Zaɓin Kayan Danye: Ana zaɓar billets na ƙarfe masu inganci don samar da bututun ƙarfe marasa matsala.

- Dumamawa da Hudawa: Ana dumama billet ɗin zuwa zafin jiki mai yawa sannan a huda su don ƙirƙirar harsashi mai rami.

- Mirgina da Girma: Sannan a naɗe harsashin da aka huda sannan a miƙe shi zuwa diamita da kauri da ake so.

- Maganin Zafi: Ana amfani da bututun wajen magance zafi kamar su toshewa ko daidaita shi don inganta halayen injin su.

- Kammalawa: Bututun suna fuskantar ayyukan kammalawa kamar miƙewa, yankewa, da kuma duba su.

- Gwaji: Ana yin gwaje-gwaje daban-daban, ciki har da gwajin hydrostatic, gwajin ultrasonic, da gwajin eddy current, don tabbatar da ingancinsu.

- Maganin Fuskar Sama: Ana iya shafa bututun ko a shafa musu magani don hana tsatsa da kuma inganta kamanninsu.

- Marufi da Jigilar Kaya: Ana shirya bututun a hankali sannan a aika su ga abokan ciniki.

2. Bututun Karfe LSAW (Waldin Arc Mai Zurfi Mai Tsawon Tsayi)

- Shirya Faranti: Ana shirya faranti masu inganci na ƙarfe don samar da bututun LSAW.

- Samarwa: Ana samar da faranti zuwa siffar "U" ta amfani da injin da ke lanƙwasawa kafin a fara amfani da shi.

- Walda: Sannan ana haɗa faranti masu siffar "U" tare ta amfani da tsarin walda mai zurfi a ƙarƙashin ruwa.

- Faɗaɗawa: Ana faɗaɗa ɗinkin da aka haɗa zuwa diamita da ake so ta amfani da injin faɗaɗawa na ciki ko na waje.

- Dubawa: Ana duba bututun don gano lahani da daidaiton girma.

- Gwajin Ultrasonic: Ana yin gwajin ultrasonic don gano duk wani lahani na ciki.

- Beveling: An yi wa ƙarshen bututun ado don walda.

- Shafi da Alama: Ana iya shafa bututun kuma a yi musu alama bisa ga buƙatun abokin ciniki.

- Marufi da Jigilar Kaya: Ana naɗe bututun kuma ana aika su ga abokan ciniki.

3. Bututun Karfe na HFW (Walda Mai Yawan Sauri):

- Shiri na na'urar: Ana shirya na'urorin ƙarfe don samar da bututun HFW.

- Samarwa da Walda: Ana samar da na'urorin zuwa siffar silinda sannan a haɗa su ta amfani da walda mai yawan mita.

- Dumama Setin Weld: Ana dumama dinkin walda zuwa zafin walda ta amfani da dumama mai yawan mita.

- Girman Bututun da aka haɗa: An auna girman bututun da aka haɗa da diamita da kauri da ake buƙata.

- Yankewa da Rage Bututu: Ana yanke bututun zuwa tsawon da ake so kuma an yi masa ƙwanƙwasa a ƙarshensa don walda.

- Dubawa: Ana duba bututun don gano lahani da daidaiton girma.

- Gwajin Hydrostatic: Ana gwada bututun don samun ƙarfi da ɓuɓɓuga ta amfani da gwajin hydrostatic.

- Shafi da Alama: Ana shafa bututun kuma ana yi musu alama bisa ga buƙatun abokin ciniki.

- Marufi da Jigilar Kaya: Ana naɗe bututun kuma ana aika su ga abokan ciniki.

Waɗannan tsare-tsare na samarwa suna tabbatar da inganci da amincin bututun ƙarfe marasa matsala, LSAW, da HFW waɗanda Womic Steel ke ƙera, suna biyan buƙatun masana'antu daban-daban.

Maganin Fuskar:

Maganin bututun mai a saman yana da matuƙar muhimmanci don inganta juriyar tsatsa da tsawon rayuwar sa. Womic Steel yana amfani da hanyoyi daban-daban na gyaran saman ya dogara da buƙatu daban-daban daga abokan ciniki, gami da:

1. Yin amfani da sinadarin galvanization a cikin ruwan zafi: Ana nutsar da bututun ƙarfe a cikin sinadarin zinc mai narkewa don samar da wani tsari mai kariya daga tsatsa, wanda ke ƙara juriya ga tsatsa. Yin amfani da sinadarin galvanizing a cikin ruwan zafi ya dace da bututun da aka saba amfani da su kuma ba su da ƙarfi sosai.

2. Rufin hana tsatsa: Rufin da aka saba amfani da shi wajen hana tsatsa sun haɗa da rufin epoxy, rufin polyethylene, da rufin polyurethane. Waɗannan rufin suna hana tsatsa da tsatsa a saman bututun ƙarfe, wanda hakan ke tsawaita tsawon rayuwarsa.

3. Fashewar Yashi: Ana amfani da fashewar gogewa mai sauri don tsaftace bututun ƙarfe, cire tsatsa da ƙazanta daga saman, wanda ke ba da kyakkyawan tushe don maganin shafa mai daga baya.

4. Maganin Shafawa: Ana iya shafa saman bututun ƙarfe da fenti mai hana lalatawa, fenti na kwalta, da sauran fenti don ƙara juriyar tsatsa, wanda ya dace da bututun ƙarƙashin ƙasa da bututun mai a cikin yanayin ruwa.

Waɗannan hanyoyin gyaran saman suna kare ƙarfen bututun mai yadda ya kamata daga tsatsa da lalacewa, suna tabbatar da amincinsa da dorewarsa a wurare daban-daban masu wahala.

Marufi da Sufuri:

Womic Steel yana tabbatar da aminci da marufi da kuma ingantaccen jigilar ƙarfen bututun, yana ba da zaɓuɓɓuka masu sassauƙa don biyan buƙatun abokan ciniki daban-daban:

1. Kaya Mai Yawa: Ga manyan oda, ana iya jigilar ƙarfe mai yawa ta amfani da manyan jiragen ruwa na musamman. Ana loda ƙarfen kai tsaye cikin ma'ajiyar jirgin ba tare da marufi ba, wanda ya dace da jigilar kayayyaki masu yawa cikin farashi mai araha.

2. LCL (Ƙasa da Nauyin Kwantena): Ga ƙananan oda, ana iya jigilar ƙarfen bututun mai a matsayin kayan LCL, inda ake haɗa ƙananan oda da yawa a cikin akwati ɗaya. Wannan hanyar tana da araha ga ƙananan adadi kuma tana ba da jadawalin isarwa mai sassauƙa.

3. FCL (Cikakken Kunshin Kwantena): Abokan ciniki za su iya zaɓar jigilar kaya ta FCL, inda aka keɓe cikakken kwantena ga odar su. Wannan hanyar tana ba da saurin lokacin jigilar kaya kuma tana rage haɗarin lalacewa yayin sarrafawa.

4. Kaya daga Sama: Ga masu yin oda cikin gaggawa, ana iya jigilar jiragen sama cikin sauri. Duk da cewa ya fi tsada fiye da jigilar jiragen ruwa, jigilar jiragen sama tana ba da jigilar kaya cikin sauri da inganci don jigilar kaya masu sauƙin ɗauka lokaci.

Kamfanin Womic Steel yana tabbatar da cewa an naɗe dukkan kayan jigilar kaya cikin aminci don hana lalacewa yayin jigilar kaya. Yawanci ana naɗe ƙarfen a cikin kayan kariya kuma ana ɗaure shi a cikin kwantena ko a kan fakiti don tabbatar da kwanciyar hankali yayin jigilar kaya. Bugu da ƙari, kamfanin yana aiki tare da abokan hulɗa na jigilar kaya masu aminci don tabbatar da isar da kaya cikin lokaci da kuma ingantaccen tsarin jigilar kaya.

Yanayin Aikace-aikace:

Ana amfani da bututun layi na API 5L da Womic Steel ke samarwa sosai a masana'antar mai da iskar gas don jigilar mai, iskar gas, da sauran ruwa. Haka kuma ana amfani da su a wasu masana'antu daban-daban kamar sarrafa sinadarai, samar da wutar lantarki, da gini.

Kammalawa:

Womic Steel amintaccen kamfanin kera bututun API 5L ne, yana ba da kayayyaki masu inganci waɗanda suka cika ƙa'idodi masu tsauri na masana'antar mai da iskar gas. Tare da mai da hankali kan inganci, aminci, da gamsuwar abokan ciniki, Womic Steel ya ci gaba da zama zaɓi mafi soyuwa ga abokan ciniki a duk duniya.

Lokacin Saƙo: Maris-22-2024