1. Bayanin Samfuri

Womic Steel amintaccen kamfanin kera bututun tagulla ne mai inganci wanda ya dace da buƙatun masu amfani da shi.ASTM B88musamman ma'auni,Nau'i Lƙayyadaddun bayanai da aka yi dagaC12200 (wanda aka cire sinadarin phosphorus daga jiki, wanda ya rage yawan sinadarin phosphorus)Ana amfani da waɗannan bututun tagulla masu tauri sosai afamfo, HVAC, tsarin kariyar wuta, iskar gas, da tsarin amfani na gabaɗayasaboda kyawun juriyarsu ga tsatsa, juriya, da kuma samuwarsu.

Tagulla na C12200 yana ɗauke da babban kaso na tagulla tsantsa da ƙaramin adadin phosphorus, wanda ke ƙara ƙarfin haɗa shi da juriya ga gurɓataccen hydrogen. Bututun Type L suna daidaita daidaito tsakanin kauri da nauyi na bango, suna ba da aminci a cikin shigarwar ƙasa da ƙasa.

2. Tsarin Samarwa

- Diamita na Waje (OD):6 mm zuwa 219 mm

- Kauri a Bango (WT):0.3mm zuwa 10mm

- Tsawon:Tsawon yau da kullun namita 3, mita 5, da mita 6, tare daTsawon musamman da ake samu akan buƙata

- Bututun da aka naɗe:Akwai a cikinNa'urori masu tsawon mita 25 ko 50don shigarwa mai sassauƙa a cikin musayar zafi

- Ƙarshen Ƙarshe:Ƙarshen ƙarshe, an tsaftace shi kuma an cire shi; yana samuwa tare da ko ba tare da huluna ba

3. Juriyar Girma (Tushen Tagulla na ASTM B88 C12200)

Womic Steel yana tabbatar da daidaiton girma daidai gaC12200bututun da aka yi daidai daASTM B88ƙa'idodi. Waɗannan haƙurin suna aiki:

ASTM B88 - Tebur 1: Girma, Nauyi, da Juriya ga Girman Bututun Ruwa na Tagulla

| Girman da Aka Ba da Shaida (in.) | Diamita na Waje (in.) | Juriya ta OD (An cire) | Juriyar OD (An zana) | Nau'in K Bango (in.) | Rubuta K Tol. (in.) | Nau'in L Bango (in.) | Nau'in L Tol. (in.) | Nau'in M Bango (in.) | Nau'in M Tol. (in.) |

| 1/4 | 0.375 | 0.002 | 0.001 | 0.035 | 0.0035 | 0.03 | 0.003 | C | C |

| 3/8 | 0.5 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.035 | 0.004 | 0.025 | 0.002 |

| 1/2 | 0.625 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.04 | 0.004 | 0.028 | 0.003 |

| 5/8 | 0.75 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.042 | 0.004 | C | C |

| 3/4 | 0.875 | 0.003 | 0.001 | 0.065 | 0.006 | 0.045 | 0.004 | 0.032 | 0.003 |

| 1 | 1.125 | 0.0035 | 0.0015 | 0.065 | 0.006 | 0.05 | 0.005 | 0.035 | 0.004 |

| 1 1/4 | 1.375 | 0.004 | 0.0015 | 0.065 | 0.006 | 0.055 | 0.006 | 0.042 | 0.004 |

| 1 1/2 | 1.625 | 0.0045 | 0.002 | 0.072 | 0.007 | 0.06 | 0.006 | 0.049 | 0.005 |

| 2 | 2.125 | 0.005 | 0.002 | 0.083 | 0.008 | 0.07 | 0.007 | 0.058 | 0.006 |

| 2 1/2 | 2.625 | 0.005 | 0.002 | 0.095 | 0.01 | 0.08 | 0.008 | 0.065 | 0.006 |

| 3 | 3.125 | 0.005 | 0.002 | 0.109 | 0.011 | 0.09 | 0.009 | 0.072 | 0.007 |

| 3 1/2 | 3.625 | 0.005 | 0.002 | 0.12 | 0.012 | 0.1 | 0.01 | 0.083 | 0.008 |

| 4 | 4.125 | 0.005 | 0.002 | 0.134 | 0.013 | 0.11 | 0.011 | 0.095 | 0.01 |

| 5 | 5.125 | 0.005 | 0.002 | 0.160 | 0.016 | 0.125 | 0.012 | 0.109 | 0.011 |

| 6 | 6.125 | 0.005 | 0.002 | 0.192 | 0.019 | 0.14 | 0.014 | 0.122 | 0.012 |

| 8 | 8.125 | 0.008 | 0.002/-0.004 | 0.271 | 0.027 | 0.2 | 0.02 | 0.17 | 0.017 |

| 10 | 10.125 | 0.008 | 0.002/-0.006 | 0.338 | 0.034 | 0.25 | 0.025 | 0.212 | 0.021 |

| 12 | 12.125 | 0.008 | 0.002/-0.006 | 0.405 | 0.04 | 0.28 | 0.028 | 0.254 | 0.025 |

A. Matsakaicin diamita na waje na bututu shine matsakaicin matsakaicin diamita na waje da mafi ƙarancin diamita na waje, kamar yadda aka ƙayyade a kowane sashe na bututun.

B Matsakaicin karkacewa a kowane wuri.

C Yana nuna cewa kayan ba a samun su gabaɗaya ko kuma cewa babu wani haƙuri da aka kafa

Waɗannan haƙurin suna tabbatar da cewa bututun sun haɗubabban daidaito da buƙatun inganci, yana sa su dace dabuƙatar aikace-aikacen masana'antu da na ruwa.

3. Sinadaran da Aka Haɗa (C12200 – ASTM B88)

Sinadarin Abun da aka haɗa (% bisa nauyi)

Tagulla (Cu) MinB≥ 99.9 (har da azurfa)

Phosphorus (P) 0.015 – 0.040

Matsakaicin iskar oxygen zai zama 10 ppm.

B Tagulla + azurfa ≤ 0.04

Abubuwan da ke cikin phosphorus suna inganta sauƙin walda da juriya ga fashewar damuwa, yayin da suke kiyaye yawan zafin jiki da wutar lantarki.

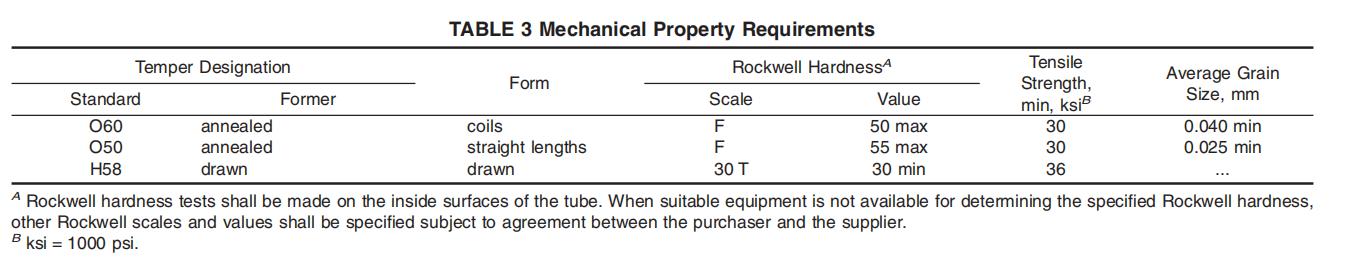

4. Kayayyakin Inji

Ana samar da bututun jan ƙarfe mai tauri na nau'in L a cikin yanayin tauri (wanda aka ja), wanda ya dace da tsarin matsi da shigarwa madaidaiciya.

5. Sharuɗɗan Isarwa

Womic Steel yana isar da bututun tagulla na Type L a cikin waɗannan yanayi:

Mai Taurin Kai (H58):Tsawon madaidaiciya don tsarin matsin lamba

Zafin da aka yi wa fenti (O60):Akwai akan buƙata don aikace-aikacen da ke buƙatar lanƙwasawa da ƙera

6. Tsarin Kera

Womic Steel yana tabbatar da inganci mai kyau da daidaito ta hanyar matakai masu zuwa:

- Narkewa & Fitarwa:Ana narkar da tagulla mai tsarki sosai sannan a jefa shi cikin billets.

- Fitarwa:Ana fitar da billets zuwa siffar tubular.

- Zane Mai Sanyi:Ana zana bututu zuwa girman ƙarshe da kauri.

- Zubar da ruwa (zaɓi ne):Idan ana buƙata, a yi wa mutum magani da zafi don rage zafi.

- Daidaitawa da Yankewa:Ana yanke bututu zuwa tsayin da aka saba ko na musamman.

- Tsaftacewa & Dubawa:Ana tsaftace kuma a duba saman ciki da waje.

- Alamar & Marufi:An yi wa bututun alama da ASTM B88, nau'i, da girma don gano su.

7. Gwaji & Dubawa

Womic Steel yana tabbatar da mafi girman ma'auni na inganci ta hanyar gudanar da ayyukagwaji da dubawa mai tsauri, ciki har da:

- Binciken Sinadaran:Tabbatarwa ta amfani da nazarin sinadarai ko na'urar tantancewa ta spectrographic

- Gwajin Taurin Kai:Tabbatar da ƙarfi da tsawaitawa sun cika buƙatun ASTM B88

- Gwajin Tauri:An auna ta amfani daHanyar Vickers

- Gwajin Faɗaɗa Tuƙi:Faɗaɗa bututun ƙarshen taKashi 30%ta amfani daMandrel mai siffar mazugi ...

- Gwajin Faɗi:Kimantawa nanakasa da juriya ga fashewa

- Gwajin Eddy na Yanzu (ECT):Ganowalahani na saman da ƙasa

- Gwajin Matsi na Hydrostatic:Tabbatar da cewa bututun suna jure wamatsin lamba na ciki ba tare da ɓuya ba

8. Yin samfur

Ana gudanar da samfura da gwaji bisa ga ka'idojin ASTM B88 da QA na ciki. Ana zaɓar samfuran gwaji bazuwar daga kowace ƙasa don:

l Abubuwan sinadarai

l Kayan aikin injiniya

Daidaiton girma

l Yanayin saman

9. Marufi

Don tabbatarwaamintaccen sarrafawa da sufuri, Womic Steel yana bayarwamafita masu ƙarfi na marufi, ciki har da:

- Rufin Hana Iskar Shaka:Ana amfani da Layer na kariya don hana tsatsa yayin ajiya da jigilar kaya

- Hulunan Ƙarshe:Murfin roba ko ƙarfe a kan ƙarshen bututu don hana gurɓatawa

- Haɗawa:An ɗaure madauri mai ƙarfi da madaurin filastik ko ƙarfe don kwanciyar hankali

- Kwandon Katako:An cushe a cikiakwatunan katako masu jure da danshitare da rufin kumfa mai kariya

- Lakabi:Kowace fakiti an yi mata lakabi daOD, WT, tsawon, yanayin, lambar batch, da ranar ƙera

10. Sufuri da Kayan Aiki

Womic Steel yana tabbatar daisarwa cikin lokaci da amincita hanyar:

- Jirgin Ruwa:Amintaccejigilar kaya zuwa cikin kwantena don rarrabawa a duk duniya

- Sufurin Jirgin Kasa da Hanya:Isarwa mai inganci ga abokan ciniki na yanki

- Gudanar da Musamman:Zaɓuɓɓukan da ke sarrafa yanayi don aikace-aikace masu mahimmanci

- Cikakken Takardu:Ciki har daTakaddun Shaidar Gwajin Masana'antu (MTC), Rahotannin Bin Ka'idojin Kayan Aiki, da Inshora

- Mafi Girman Juriya ga Tsatsa:Madalla daaikace-aikacen canja wurin zafi, sinadarai, da ruwa

- Daidaita Manufacturing:Tsananihaƙurin girmadon mafi kyawun aiki

- Magani na Musamman:Girman da aka ƙera, yanayin zafi, da kuma rufin da aka ƙera don biyan buƙatun musamman

- Gwaji Mai Cikakke:Tabbatar da cikakken bin ƙa'idodiASTM B88

- Cibiyar Rarrabawa ta Duniya:Isar da kaya cikin sauri da aminci a duk duniya

11. Fa'idodin Zaɓar Ƙarfe Mai Tsami

12. Aikace-aikace

NamuASTM B88 C12200bututun sun dace da:

- Masana'antar Ruwa: Masu sanyaya ruwan teku, bututun mai, da na'urorin musayar zafi na jirgin ruwa

- Cibiyoyin Wutar Lantarki:Masu sanyaya tururi da kumatsarin sanyaya

- Shuke-shuken tace gishiri:Bututun da ke jure tsatsa don amfani da ruwan gishiri

- Sarrafa Sinadarai:Bututun musayar zafi mai ƙarfi, mai matsin lamba mai zafi

- HVAC & Firji: Na'urorin sanyaya iska da tsarin sanyaya masana'antu

Kammalawa

Bututun tagulla na ASTM B88 C12200 Type L na Womic Steel suna ba da aiki mai kyau, dorewa, da juriya ga tsatsa, wanda hakan ya sa suka zama zaɓi mafi kyau ga tsarin bututu iri-iri. Tare da bin ƙa'idodin ASTM da cikakken tabbacin inganci, muna tabbatar da cewa kowane isarwa ya cika mafi girman tsammanin aiki da aminci.

Muna alfahari da kanmu a matsayinmuayyukan keɓancewa, saurin samar da da'ira, kumahanyar sadarwar isar da sako ta duniya, tabbatar da cewa an biya buƙatunku na musamman da daidaito da inganci.

Yanar Gizo: www.womicsteel.com

Imel: sales@womicsteel.com

Waya/WhatsApp/WeChat: Victor: +86-15575100681 ko Jack: +86-18390957568

Lokacin Saƙo: Janairu-21-2026