1.Bayanin Samfuri

Womic Steel ta ƙware wajen samar da bututun tagulla masu inganci waɗanda suka dace da ƙa'idar EN 1057. An yi waɗannan bututun ne da kayan Cu-DHP (CW024A), suna tabbatar da tsafta da aiki na musamman don aikin famfo, rarraba iskar gas, dumama, da sanyaya. Tare da ƙarancin sinadarin jan ƙarfe da azurfa na 99.9% da kuma kewayon phosphorus mai sarrafawa tsakanin 0.015% da 0.040%, bututun tagulla ɗinmu suna nuna juriya mai kyau ga tsatsa, dorewa, da sauƙin shigarwa.

An ƙera bututun tagulla na EN 1057 don amfani a cikin gidaje da masana'antu, suna ba da ingantaccen aiki a cikin tsarin ruwa mai sha, dumama ta tsakiya, sanyaya, da bututun iskar gas na likitanci. An ƙera waɗannan bututun bisa ƙa'idodi masu tsauri, suna ba da ingantattun kaddarorin injiniya da amincin sabis na dogon lokaci.

2.TS EN 1057 Bututun Copper Samfuran Rage

● Diamita na Waje (OD):6 mm zuwa 267 mm

●Kauri a Bango (WT):0.3mm zuwa20mm

●Tsawon:Tsawon yau da kullun na mita 3, mita 5, ko mita 6; ana iya samun tsayin musamman idan an buƙata

●Bututun da aka naɗe:Akwai shi a cikin na'urori masu tsawon mita 25 ko 50 don shigarwa mai sassauƙa

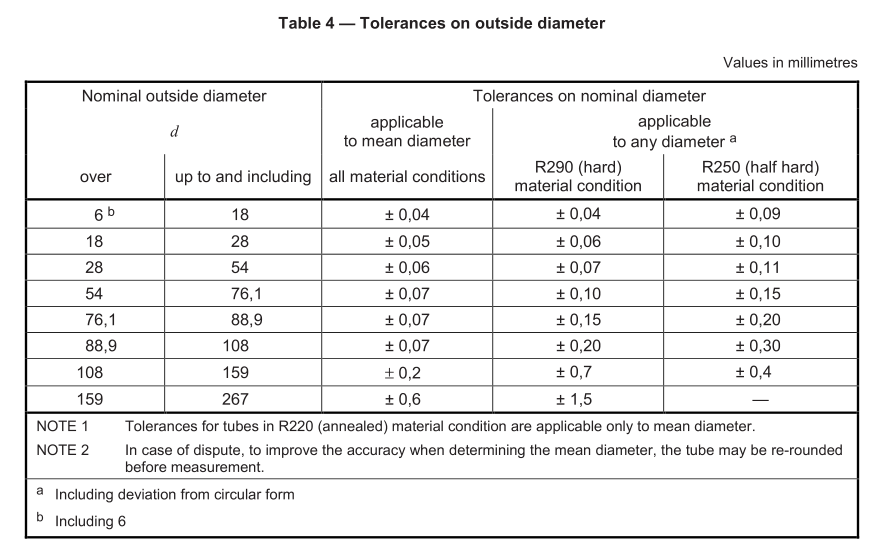

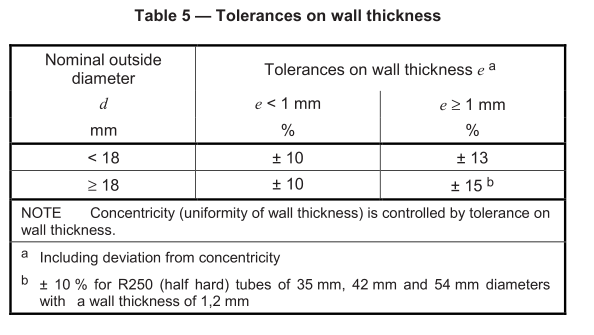

3.TS EN 1057 Hakuri da Bututun Copper

Womic Steel yana tabbatar da daidaiton girma daidai gwargwado tare da waɗannan haƙurin:

4.Tsarin Sinadaran Bututun Tagulla na EN 1057

Ana ƙera bututun jan ƙarfe namu daga kayan Cu-DHP (CW024A) tare da abun da ke ciki mai zuwa:

Tsarin zai bi waɗannan buƙatu:

Cu + Ag: min. 99,90%;

0,015 %≤P≤0,040 %.

An sanya wannan matakin jan ƙarfe ko dai Cu-DHP ko CW024A.

Wannan abun da ke ciki yana tabbatar da kyakkyawan juriya ga tsatsa, yawan zafin jiki da wutar lantarki, da kuma ingantaccen aiki.

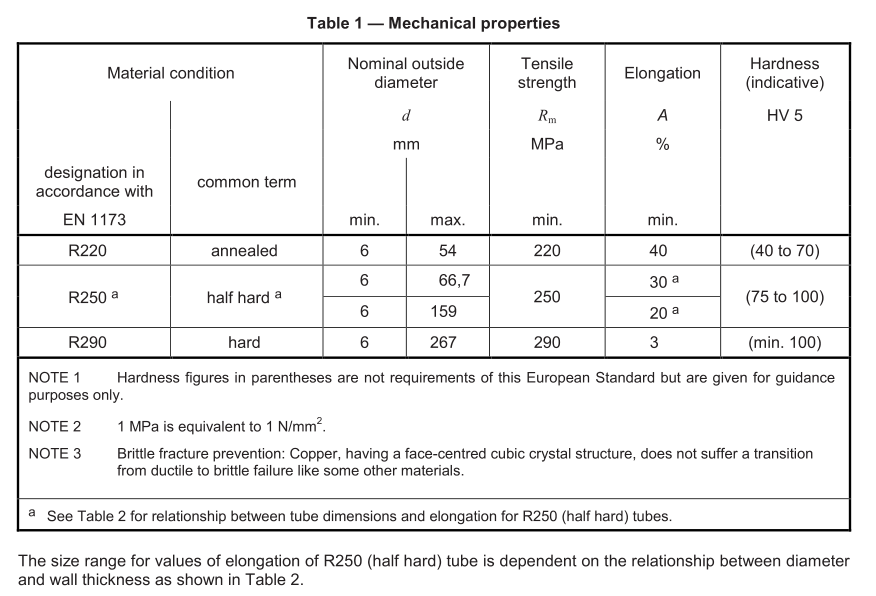

5.Kayayyakin Inji na Bututun Tagulla na EN 1057

Kayayyakin injina na bututun tagulla na EN 1057 sun dogara ne akan yanayin isarwa:

6.Ka'idojin Isarwa na Bututun Tagulla na EN 1057

Womic Steel yana samar da bututun tagulla na EN 1057 a cikin waɗannan yanayi:

●R220 (An rufe shi da roba): Mai sassauƙa sosai, ya dace da lanƙwasawa da ƙera

●R250 (Rabin-Turi): Ƙarfi matsakaici, daidaito mai kyau na sassauci da juriya

●R290 (Mai Tauri): Ƙarfi mai yawa, ya dace da aikace-aikace madaidaiciya tare da ƙarancin lanƙwasawa

7.Tsarin Kera Bututun Tagulla na EN 1057

Tsarin samar da kayayyaki namu na ci gaba yana tabbatar da mafi girman ƙa'idodi masu inganci:

1.Shirye-shiryen Siminti da Billet: Ana narkar da jan ƙarfe mai tsarki sosai sannan a jefa shi cikin billets.

2. Fitar da Kaya da Huda: Ana fitar da billets zuwa cikin bututu sannan a huda su gwargwadon girman da ake buƙata.

3. Zane Mai Sanyi: Ana zana bututu ta cikin injinan kashe gobara don cimma daidaiton girma.

4.Annealing: Ana amfani da maganin zafi don cimma halayen injiniya da ake buƙata.

5. Daidaitawa da Yankewa: Ana miƙe bututun kuma ana yanke su zuwa tsayin da ake buƙata.

6. Dubawa da Gwaji: Dubawa mai tsauri na inganci yana tabbatar da bin ƙa'idodin EN 1057.

8.Gwaji & Dubawa

Womic Steel yana ba da garantin cikakken iko mai inganci tare da cikakken gwaji, gami da:

●Nazarin Sinadarai/Nazarin Spectrographic: Tabbatar da abun da ke cikin abu ta amfani da hanyoyin sinadarai ko na spectroscopic.

●Gwajin Taurin Kai: Kimanta ƙarfin Taurin Kai da kuma ƙa'idodin tsawaitawa (EN 10002-1).

●Gwajin Tauri: Auna tauri ta hanyar amfani da hanyar Vickers (EN ISO 6507-1).

●Gwajin Abubuwan Carbon: Ƙayyade adadin kashi na carbon ta amfani da hanyar da aka yi amfani da ita ta EN 723.

●Gwajin Fim ɗin Carbon: Ganowa da tantance kasancewar fim ɗin carbon (Annex B).

●Gwajin Lanƙwasawa: Kimanta lanƙwasawa a ƙarƙashin

● Gwajin Faɗaɗawa: Faɗaɗa ƙarshen bututu da kashi 30% tare da45°mandrel mai siffar mazugi don tabbatar da dorewar aiki (EN ISO 8493).

● Gwajin Flanging: Tabbatar da samuwar flange (ƙara mafi ƙarancin 30% a diamita na bututu) ta amfani da kayan aiki mai radius na kusurwa 1 mm (EN ISO 8494).

● Gwaje-gwajen 'Yanci daga Lalacewa:

● Gwajin Yanzu na Eddy (ECT): Gano lahani na saman/ƙasa (EN 1971 & Annex C.1).

● Gwajin Hydrostatic: Tabbatar da juriya ga matsi ta hanyar matsin lamba na ruwa (Annex C.2).

● Gwajin Huhu: Gano zubewar iska ta amfani da matsin iska/iska (Annex C.3).

●Lura: Gwajin nau'in farko yana buƙatar ECT; sauran hanyoyin zaɓin masana'anta ne.

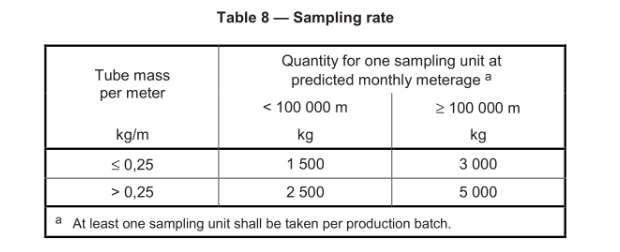

9. Samfurin samfur:

Domin tabbatar da inganci yayin samarwa, adadin na'urorin da za a ɗauka a bazata za a kasancedaidai da Tebur 8.

Waɗannan ƙimar samfurin za su yi aiki lokacin gwada ikon sarrafawa na girma; za a gudanar da ikon sarrafa wasu kaddarorin da suka wajaba akan kowace naúrar samfurin ta biyu.

Ana iya amfani da sakamakon daga nazarin da aka gudanar a matakin farko na ƙera samfurin, misali a matakin jefawa ko kuma a cikin matakin, idan an kiyaye asalin samfurin kuma ko tsarin kula da inganci na masana'anta ya cika buƙatun EN lSO 9001.

10.Marufi

Domin tabbatar da aminci wajen sarrafawa da jigilar kaya, an shirya bututun jan ƙarfe kamar haka:

●Shafin Hana Iskar Oxidation: Ana amfani da wani Layer mai kariya a saman bututun jan ƙarfe don hana iskar oxidation da canza launi yayin ajiya da jigilar kaya.

●Murfin Ƙarshe: Ana sanya murfi na ƙarfe masu jure wa lalatawa ko na roba a kan ƙarshen bututu don hana gurɓatawa da lalacewar injiniya.

●Haɗawa: Ana haɗa bututu ta hanyar takamaiman bayanai kuma an ɗaure su da madauri mai ƙarfi na filastik don rage motsi yayin jigilar kaya.

●Kwantenan Katako: Ana sanya bututun da aka haɗa a cikin akwatunan katako masu jure da danshi. An lulluɓe akwatunan da kumfa mai hana ruwa shiga ko kayan bushewa don hana lalacewar danshi da kuma bin ƙa'idodin tsabtace jiki na duniya na ISPM 15.

● Rufe Akwatunan da aka Ƙarfafa: Ana rufe akwatunan da madaurin ƙarfe ko maƙallan da aka yi wa nauyi. Akwai zaɓi na naɗewa don ƙarin kariya daga yanayi.

●Lakabi: Kowace akwati an yi mata lakabi da diamita na waje na bututun (OD), kauri na bango (WT), tsayi, yanayin zafi (misali, laushi, rabin tauri), lambar rukunin samarwa, da kwanan wata don tabbatar da cikakken ganowa.

11.Sufuri & Jigilar Kaya

Womic Steel yana tabbatar da isar da bututun tagulla na EN 1057 akan lokaci da aminci:

●Jirgin Ruwa: Jigilar kaya ta duniya a cikin kwantena tare da ingantaccen tsaro

●Jirgin ƙasa ko Sufuri: Isassun kayayyaki masu inganci a cikin gida da na yanki

●Sufuri Mai Kula da Yanayi: Akwai don aikace-aikace masu mahimmanci

●Takardu Masu Cikakke: Takardun jigilar kaya da inshora da aka bayar

●Tsarkakken Tagulla: Ƙarfin juriya da juriyar tsatsa

●Kayan aiki masu inganci: Juriyar girma mai tsauri don ingantaccen aiki

●Maganin Musamman: Tsawon jiki, yanayin jiki, da kuma rufin da aka ƙera suna samuwa

●Gwaji Mai Cikakke: Tabbatar da bin ƙa'idodin ƙasashen duniya

●Rarraba Duniya: Isarwa mai inganci da kuma kan lokaci a duk duniya

12.Fa'idodin Zaɓar Womic Steel

- ●Tsarkakken Tagulla: Ƙarfin juriya da juriyar tsatsa

- ●Kayan aiki masu inganci: Juriyar girma mai tsauri don ingantaccen aiki

- ●Maganin Musamman: Tsawon jiki, yanayin jiki, da kuma rufin da aka ƙera suna samuwa

- ●Gwaji Mai Cikakke: Tabbatar da bin ƙa'idodin ƙasashen duniya

- ●Rarraba Duniya: Isarwa mai inganci da kuma kan lokaci a duk duniya

13.Aikace-aikace

Ana amfani da bututun tagulla na EN 1057 sosai a cikin:

- Tsarin Bututun Ruwa: Rarraba ruwan sha cikin aminci da inganci

- Rarraba Iskar Gas: Ya dace da amfani da iskar gas da LPG

- Tsarin Dumamawa: Ingancin aiki a cikin radiators da dumama ƙasa

- Firji da Kwandishan: Babban ƙarfin lantarki mai zafi don tsarin sanyaya

- Bututun Iskar Gas na Likitanci: Amintacce a asibitoci don iskar oxygen da iskar gas na likita

Kammalawa

Man Fetur na EN 1057 na Womic Steel suna ba da inganci, ƙarfi, da aminci ga aikace-aikacen famfo, iskar gas, da masana'antu. Jajircewarmu ga kera kayayyaki daidai, gwaji mai tsauri, da kuma mafita mai da hankali kan abokan ciniki ya sa mu zama abokin tarayya mai aminci a masana'antar.

Zaɓi Womic Steel Group a matsayin abokin tarayya mai aminci don inganci mai kyauBututun Tagulla&Samfuri da kuma aikin isar da kaya mai ban mamaki. Barka da zuwa Tambaya!

Yanar Gizo: www.womicsteel.com

Imel: sales@womicsteel.com

Waya/WhatsApp/WeChat: Victor: +86-15575100681 ko Jack: +86-18390957568

Lokacin Saƙo: Maris-10-2025