Menene flange?

Flange a takaice, kawai kalma ce ta gabaɗaya, yawanci yana nufin wani ƙarfe mai kama da faifai don buɗe wasu ramuka masu gyara, waɗanda ake amfani da su don haɗa wasu abubuwa, wannan nau'in abu ana amfani da shi sosai a cikin injina, don haka yana kama da ɗan abin mamaki, matuƙar an san shi da flange, sunansa ya samo asali ne daga flange na Ingilishi. don haka bututun da bututun haɗin sassan, waɗanda aka haɗa zuwa ƙarshen bututun, flange yana da buɗaɗɗen buɗewa, sukurori don yin flange biyu. An haɗa su sosai, tsakanin flange tare da hatimin gasket.

Flange sassa ne masu siffar faifai, waɗanda aka fi sani da su a fannin injiniyan bututun, ana amfani da flange a nau'i-nau'i biyu.

Dangane da nau'ikan haɗin flange, akwai sassa uku:

- Flanges na bututu

- Gasket

- Haɗin Bolt

A mafi yawan lokuta, akwai takamaiman kayan gasket da bolt da aka samo wanda aka yi daga abu ɗaya da ɓangaren flange na bututu. Flanges mafi yawan su ne flanges na bakin ƙarfe. Flanges, a gefe guda, suna samuwa a cikin nau'ikan kayan aiki daban-daban don dacewa da buƙatun wurin. Wasu daga cikin kayan flange mafi yawan su ne monel, inconel, da chrome molybdenum, ya danganta da ainihin buƙatun wurin. Mafi kyawun zaɓin kayan ya kamata ya dogara da nau'in tsarin da kuke son amfani da flange tare da takamaiman buƙatu.

Nau'ikan Flanges guda 7 da aka fi sani

Akwai nau'ikan flanges daban-daban da za a iya zaɓa bisa ga buƙatun wurin. Domin daidaita ƙirar flanges ɗin da ya dace, dole ne a tabbatar da ingantaccen aiki da tsawon rai na sabis kuma a yi la'akari da farashi mafi dacewa.

1. flange mai zare:

An sanya wayoyi masu zare, waɗanda ke da zare a cikin ramin flange, zare na waje a kan madauri. Haɗin zare an yi shi ne don guje wa walda a kowane hali. Yawanci ana haɗa shi ta hanyar haɗa zare da bututun da za a saka.

2. Flanges na walda na socket

Ana amfani da wannan nau'in flange ga ƙananan bututu inda diamita na yankin ƙarancin zafin jiki da ƙarancin matsin lamba ke da alaƙa da haɗin da aka sanya bututun a cikin flange don tabbatar da haɗin gwiwa da walda ɗaya ko ta hanyoyi da yawa. Wannan yana guje wa ƙuntatawa da ke da alaƙa da ƙarshen zare idan aka kwatanta da sauran nau'ikan flange da aka haɗa, don haka yana sa shigarwa ya zama mai sauƙi.

3. Flanges na cinya

Flange na cinya wani nau'in flange ne wanda ke buƙatar a haɗa ƙarshen stub ɗin da duwawu don a yi amfani da shi tare da flange mai tallafi don samar da haɗin flange. Wannan ƙirar ta sa wannan hanyar ta shahara a cikin tsarin da yawa inda sarari na zahiri yake da iyaka, ko kuma inda ake buƙatar raba shi akai-akai, ko kuma inda ake buƙatar kulawa mai yawa.

4. Zamiya flanges

Flanges masu zamiya sun zama ruwan dare gama gari kuma ana samun su a cikin girma dabam-dabam don dacewa da tsarin da ke da yawan kwararar ruwa da kuma fitar da iska. Kawai daidaita flanges ɗin da diamita na waje na bututun yana sa haɗin ya zama mai sauƙin shigarwa. Shigar da waɗannan flanges ɗin yana da ɗan fasaha domin yana buƙatar walda a ɓangarorin biyu don ɗaure flanges ɗin da bututun.

5. Ƙunƙun makafi

Waɗannan nau'ikan flanges sun dace sosai don ƙare tsarin bututu. Farantin makafi yana kama da faifan faifai mara komai wanda za'a iya ɗaure shi da ƙulli. Da zarar an shigar da su yadda ya kamata kuma an haɗa su da gasket ɗin da ya dace, yana ba da damar yin kyakkyawan hatimi kuma yana da sauƙin cirewa lokacin da ake buƙata.

6. Ƙunƙwasa Wuya na Weld

Flanges ɗin wuyan walda suna kama da flanges na cinya, amma suna buƙatar walda na duwawu don shigarwa. Kuma ingancin aikin wannan tsarin da ikon lanƙwasa shi sau da yawa kuma ana amfani da shi a cikin tsarin matsin lamba mai yawa da zafin jiki mai yawa ya sa ya zama babban zaɓi na bututun sarrafawa.

7. Flanges na musamman

Wannan nau'in flange shine mafi shahara. Duk da haka, akwai nau'ikan flange na musamman iri-iri da ake da su don dacewa da amfani da muhalli iri-iri. Akwai wasu zaɓuɓɓuka daban-daban kamar flange nipo, flange weldo, flange na faɗaɗawa, ramuka, dogayen wuyan walda da flange masu ragewa.

Nau'ikan Flanges guda 5 na Musamman

1. WeldoFlange

Flange na Weldo yayi kama da flange na Nipo domin yana da haɗin flange na ƙwanƙwasa da haɗin haɗin rassan. Ana yin flange na Weldo daga ƙarfe guda ɗaya mai ƙarfi, maimakon a haɗa sassan daban-daban.

2. Nipo flange

Nipoflange bututu ne mai rassa wanda aka karkata a kusurwar digiri 90, wani samfuri ne da aka ƙera ta hanyar haɗa flanges ɗin walda da Nipolet ɗin da aka ƙera. Duk da cewa ana ganin flange Nipo a matsayin ƙarfe mai ƙarfi guda ɗaya da aka ƙera, ba a fahimci cewa samfura biyu ne daban-daban da aka haɗa su wuri ɗaya ba. Shigar da Nipoflange ya ƙunshi walda a ɓangaren Nipolet na kayan aiki don sarrafa bututun da kuma haɗa ɓangaren flange zuwa flange ɗin bututun da ma'aikatan bututun ke amfani da shi.

Yana da mahimmanci a san cewa ana samun flanges na Nipo a cikin nau'ikan kayayyaki daban-daban kamar carbon, ƙarfe mai zafi da ƙarancin zafin jiki, matakan ƙarfe na bakin ƙarfe, da kuma ƙarfe na nickel. Ana yin flanges na Nipo galibi da ƙera su da ƙarfi, wanda ke taimakawa wajen ba su ƙarin ƙarfi na injiniya idan aka kwatanta da flange na Nipo na yau da kullun.

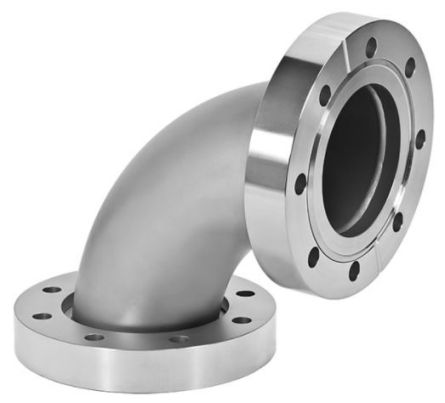

3. Elboflange da Latroflange

Ana kiran Elboflange da haɗin flange da Elbolet yayin da ake kiran Latroflange da haɗin flange da Latrolet. Ana amfani da flanges na Elbow don reshe bututu a kusurwar digiri 45.

4. Ƙwallon zobe mai juyawa

Amfani da flanges na zobe masu juyawa shine don sauƙaƙe daidaita ramukan bolt tsakanin flanges guda biyu masu haɗin gwiwa, wanda ya fi taimako a yanayi da yawa, kamar shigar da manyan bututun mai, bututun ƙarƙashin ruwa ko na teku da makamantansu. Waɗannan nau'ikan flanges sun dace da ruwa mai buƙata a cikin mai, iskar gas, hydrocarbons, ruwa, sinadarai da sauran aikace-aikacen sarrafa man fetur da ruwa.

Idan aka yi la'akari da manyan bututun da ke da diamita, ana sanya bututun da flange na al'ada a gefe ɗaya da kuma flange mai juyawa a ɗayan gefen. Wannan yana aiki ne kawai ta hanyar juya flange mai juyawa akan bututun don mai aiki ya sami daidaito mai kyau na ramukan ƙulli cikin sauƙi da sauri.

Wasu daga cikin manyan ƙa'idodi don flanges na zobe masu juyawa sune ASME ko ANSI, DIN, BS, EN, ISO, da sauransu. Ɗaya daga cikin shahararrun ƙa'idodi don aikace-aikacen petrochemical shine ANSI ko ASME B16.5 ko ASME B16.47. Flanges masu juyawa sune flanges waɗanda za a iya amfani da su a cikin dukkan siffofi na flange na gama gari. Misali, wuyan walda, zamewa, haɗin gwiwa na lap, walda soket, da sauransu, a cikin dukkan matakan kayan aiki, a cikin girma dabam-dabam daga 3/8" zuwa 60", da matsin lamba daga 150 zuwa 2500. Ana iya ƙera waɗannan flanges cikin sauƙi daga carbon, gami, da ƙarfe bakin ƙarfe.

5. Faɗaɗa flanges

Ana amfani da faffadan bututu don ƙara girman ramin bututu daga kowane wuri zuwa wani domin haɗa bututun da duk wani kayan aikin injiniya kamar famfo, na'urorin compressor, da bawuloli waɗanda aka gano suna da girman shigarwa daban-daban.

Flanges na faɗaɗawa galibi flanges ne masu ɗaure da butt waɗanda ke da babban rami a ƙarshen da ba shi da flange. Ana iya amfani da shi don ƙara girma ɗaya ko biyu kawai ko har zuwa inci 4 zuwa ramin bututun gudu. Waɗannan nau'ikan flanges an fi son su fiye da haɗakar masu rage butt-weld da flanges na yau da kullun saboda suna da rahusa kuma suna da sauƙi. Ɗaya daga cikin kayan da aka fi amfani da su don flanges na faɗaɗawa shine A105 da bakin ƙarfe ASTM A182.

Ana samun flanges na faɗaɗawa a ma'aunin matsin lamba da girma dabam-dabam daidai da ƙayyadaddun bayanai na ANSI ko ASME B16.5, waɗanda galibi ana samun su a cikin convex ko lebur (RF ko FF). Rage flanges, wanda kuma aka sani da rage flanges, suna aiki daidai da aikin da akasin haka idan aka kwatanta da flanges na faɗaɗawa, ma'ana ana amfani da su don rage girman bututu. Ana iya rage diamita na bututun da ke gudana cikin sauƙi, amma ba fiye da girma 1 ko 2 ba. Idan an yi ƙoƙarin ragewa fiye da haka, ya kamata a yi amfani da mafita bisa ga haɗakar masu rage butt da flanges na yau da kullun.

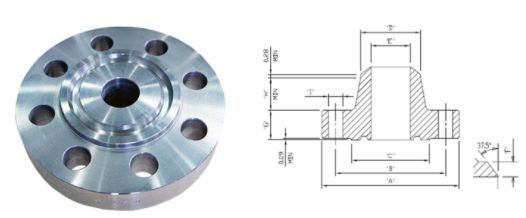

Girman Flange da Abubuwan da Aka Fi So

Baya ga tsarin aikin flange, girmansa shine abin da zai iya tasiri ga zaɓin flange lokacin tsara, kulawa da sabunta tsarin bututu. Madadin haka, dole ne a yi la'akari da hanyar haɗin flange tare da bututun da gaskets da ake amfani da su don tabbatar da girman da ya dace. Baya ga wannan, wasu abubuwan da aka fi la'akari da su sune kamar haka:

- Diamita na waje: Diamita na waje shine nisan da ke tsakanin gefuna biyu masu gaba da juna na fuskar flange.

- Kauri: Ana auna kauri daga wajen gefen.

- Diamita na Da'irar Bolt: Wannan shine nisan da ke tsakanin ramukan ƙugiya masu alaƙa da juna waɗanda aka auna daga tsakiya zuwa tsakiya.

- Girman Bututu: Girman bututun shine girman da ya dace da flange.

- Ramin da aka yi da suna: Ramin da aka yi da suna shine girman diamita na ciki na mahaɗin flange.

Rarraba Flange da Matsayin Sabis

Ana rarraba flanges ta hanyar ikonsu na jure yanayin zafi da matsin lamba daban-daban. Ana sanya shi ta hanyar amfani da haruffa ko kari "#", "lb" ko "class". Waɗannan kari ne masu canzawa kuma suna bambanta ta yanki ko mai kaya. An jera rarrabuwa da aka sani a ƙasa:

- 150#

- 300#

- 600#

- 900#

- 1500#

- 2500#

Matsi da jurewar zafin jiki iri ɗaya sun bambanta dangane da kayan da aka yi amfani da su, ƙirar flange da girman flange. Duk da haka, abin da kawai ke canzawa shine ƙimar matsin lamba, wanda ke raguwa yayin da zafin jiki ke ƙaruwa.

Nau'in Fuskar Flange

Nau'in fuska kuma muhimmin siffa ne wanda ke da tasiri sosai ga aikin ƙarshe da tsawon lokacin sabis na flange. Saboda haka, an yi nazarin wasu daga cikin mahimman nau'ikan fuskokin flange a ƙasa:

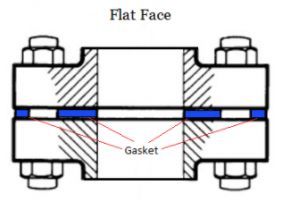

1. Flange mai faɗi (FF)

Fuskar gasket ɗin flange mai faɗi tana cikin irin yanayin da saman firam ɗin da aka ɗaure. Kayayyakin da ke amfani da flange mai faɗi galibi waɗanda aka ƙera su da molds don dacewa da murfin flange ko flange. Bai kamata a sanya flange mai faɗi a kan flange na gefe da aka juya ba. ASME B31.1 ta bayyana cewa lokacin da aka haɗa flange na ƙarfe mai faɗi zuwa flange na ƙarfe mai faɗi, dole ne a cire fuskar da aka ɗaga a kan flange na ƙarfe mai faɗi kuma ana buƙatar gasket ɗin fuska gaba ɗaya. Wannan don hana ƙananan flange na ƙarfe mai ƙarfi su faɗuwa cikin ramin da hancin ƙarfe mai tsayi ya samar.

Ana amfani da wannan nau'in fuskar flange wajen ƙera kayan aiki da bawuloli don duk aikace-aikacen da ake ƙera ƙarfen siminti. Iron ɗin siminti yana da ƙarfi sosai kuma yawanci ana amfani da shi ne kawai don aikace-aikacen ƙarancin zafi da ƙarancin matsin lamba. Fuskar lebur tana ba da damar duka flanges ɗin su yi cikakken hulɗa a saman gaba ɗaya. Flanges masu lebur (FF) suna da saman hulɗa wanda tsayinsa yayi daidai da zaren ƙulli na flange. Ana amfani da wankin fuska cikakke tsakanin flanges guda biyu masu lebur kuma yawanci suna da laushi. A cewar ASME B31.3, flanges masu lebur bai kamata a haɗa su da flanges masu tsayi ba saboda yuwuwar zubewa daga haɗin flange da ya haifar.

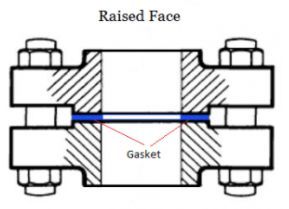

2. Flange mai ɗagawa (RF)

Fuskar da aka ɗaga ita ce nau'in da aka fi amfani da shi a aikace-aikacen masana'anta kuma ana iya gane ta cikin sauƙi. Ana kiranta convex saboda fuskar gasket ɗin tana saman fuskar zoben ƙulli. Kowace nau'in fuska tana buƙatar amfani da nau'ikan gaskets da yawa, gami da nau'ikan sandunan zobe masu faɗi da haɗakar ƙarfe kamar su raunuka masu karkace da siffofi masu kauri biyu.

An tsara flanges na RF don ƙara matsa lamba a kan ƙaramin yanki na gasket, don haka inganta sarrafa matsin lamba na haɗin gwiwa. diamita da tsayi ta matakin matsin lamba da diamita an bayyana su a cikin ASME B16.5. Matsayin matsin lamba na flange yana ƙayyade tsayin fuskar da ake ɗagawa. Flanges na RF an yi niyya ne don ƙara matsa lamba a kan ƙaramin yanki na gasket, don haka ƙara ƙarfin sarrafa matsin lamba na haɗin gwiwa. Diamita da tsayi ta hanyar ajin matsin lamba da diamita an bayyana su a cikin ASME B16.5. Matsayin flange na matsi.

3. Flange na zobe (RTJ)

Idan ana buƙatar hatimin ƙarfe tsakanin flanges ɗin da aka haɗa (wanda shine yanayin amfani da shi a yanayin matsin lamba mai yawa da zafin jiki mai yawa, watau sama da 700/800 C°), ana amfani da Flange na Haɗin Zobe (RTJ).

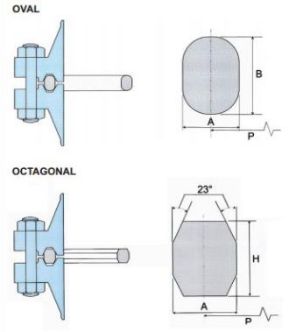

Flange ɗin haɗin zobe yana da rami mai zagaye wanda ke ɗaukar gasket ɗin haɗin zobe (oval ko rectangular).

Idan aka haɗa maƙullan haɗin zobe guda biyu sannan aka matse su, ƙarfin maƙullan da aka yi amfani da shi yana canza gasket ɗin da ke cikin ramin maƙullan, yana ƙirƙirar hatimin ƙarfe mai matsewa sosai. Domin cimma wannan, kayan da ke cikin maƙullan haɗin zoben dole ne su yi laushi (mafi laushi) fiye da kayan da ke cikin maƙullan.

Ana iya rufe flanges na RTJ da gaskets na RTJ iri daban-daban (R, RX, BX) da kuma bayanan martaba (misali, octagonal/elliptical don nau'in R).

Gasket ɗin RTJ da aka fi sani shine nau'in R mai sashe mai kusurwa huɗu, domin yana tabbatar da hatimi mai ƙarfi sosai (sashe mai kusurwa huɗu shine tsohon nau'in). Duk da haka, ƙirar "lebur mai faɗi" tana karɓar nau'ikan gasket ɗin RTJ guda biyu tare da sashe mai kusurwa huɗu ko kuma mai kusurwa huɗu.

4. Harshe da tsagi masu lanƙwasa (T & G)

Flanges guda biyu na harshe da rago (fuskokin T & G) sun dace daidai: flange ɗaya yana da zobe mai ɗagawa ɗayan kuma yana da ramuka inda suke dacewa cikin sauƙi (harshe yana shiga cikin ramin kuma yana rufe haɗin).

Ana samun flanges na harshe da na tsagi a manyan da ƙanana.

5. Famfon Namiji da Na Mata (M & F)

Kamar flanges na harshe da groove, flanges na maza da mata (nau'ikan fuska na M & F) suna daidai da juna.

Ɗaya daga cikin flange yana da yanki wanda ya wuce samansa, flange na namiji, ɗayan kuma yana da ramuka masu dacewa da aka ƙera a saman da ke fuskantar, flange na mace.

Ƙarshen saman flange

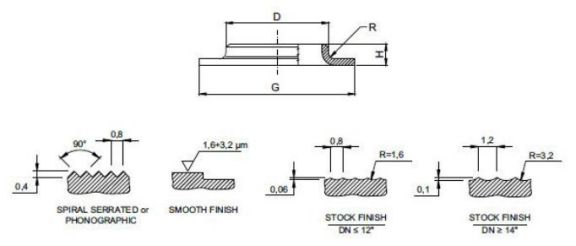

Domin tabbatar da dacewa da flange ɗin da gasket ɗin da flange ɗin da suka haɗu, yankin saman flange yana buƙatar wani matakin kauri (ƙarshen flange na RF da FF kawai). Nau'in kauri na saman fuskar flange yana bayyana nau'in "ƙarshen flange".

Nau'ikan da aka fi sani sune fuskokin flange masu santsi, masu siffar serrated mai kauri, masu siffar spiral da kuma masu siffar flange masu santsi.

Akwai ƙa'idodi guda huɗu na saman flanges na ƙarfe, duk da haka, burin gama gari na kowane nau'in ƙa'idar saman flange shine samar da ƙazanta da ake so akan saman flange don tabbatar da daidaito mai ƙarfi tsakanin flange, gasket da mating flange don samar da hatimi mai inganci.

Lokacin Saƙo: Oktoba-08-2023