1. Gabatarwa ga Bututun Rage Nauyi Mai Nauyi

Bututun haƙa bututun haƙa abubuwa ne masu mahimmanci waɗanda ke haɗa kayan aikin saman zuwa kayan aikin ramin ƙasa.Bututun Rage Nauyi Mai Nauyi (HWDP), a matsayin bututun haƙa na musamman, suna aiki a matsayin wani abu mai canzawa tsakanin bututun haƙa na yau da kullun da abin wuya na haƙa. Ta hanyar ingantaccen ƙirar tsari da kayan aiki na zamani, HWDP tana taka muhimmiyar rawa wajen ɗaukar kaya, rage girgiza, da daidaita yanayin rijiya a ƙarƙashin yanayi mai rikitarwa na haƙa.

Mahimman Siffofin Zane:

Canjin TsarinBututun haƙa rami mai "sauƙi" da kuma abin wuya mai "tsauri", wanda ke rage yawan damuwa a wuraren haɗuwa.

Ƙarfin Bango Mai Inganci: Kauri sau 2-3 fiye da bututun haƙa na yau da kullun yayin da ake kiyaye diamita iri ɗaya na waje (misali, φ50 mm, φ89 mm) don dacewa da aiki.

Aikace-aikace Masu Aiki da yawa: Yana maye gurbin abin wuyan haƙa rami mai siriri, yana rage ƙarfin juyi da haɗarin bututun da ke makale a cikin rijiyoyin da ke fuskantar hanya, kuma yana ba da damar sarrafa ma'aunin nauyi akan bit (WOB).

2. Tsarin Tsarin: Tabbatar da Ƙarfi da Juriyar Sakawa Biyu

2.1 Tsarin Jikin Bututu

Tsarin da ya ɓata rai: Na ciki, na waje, ko kuma na haɗin gwiwa a ƙarshen bututu don haɓaka juriyar matsi da aikin gajiya.

Damuwa ta Cikin Gida: Yana kula da diamita na waje don ƙananan ramukan rijiyoyi.

Tashin Hankali na Waje: Yana ƙara ƙarfin ɗaukar nauyi na axial don rijiyoyin tsaye.

Haɗakar Haɗaka: Mafi kyau ga yanayi mai tsauri kamar rijiyoyi masu zurfi sosai.

Zaɓin Kayan Aiki: Gasolin ƙarfe masu ƙarfi (misali, 4145H MOD) tare da ƙarfin yawan amfanin ƙasa daga 55,000 zuwa 110,000 KSI.

2.2 Fasahar Haɗin Kayan Aiki

Haɗin Kayan Aiki Mai Faɗi: Ƙara yankin hulɗa don rarraba tashin hankali, matsi, da nauyin juyawa.

Hanyoyin Haɗi:

Haɗin da aka Zare: API ko zare mai kafada biyu tare da manne don hana zubewa.

Tsarin da aka haɗa: Haɗaɗɗen haɗin gwiwa da aka ƙera don amfani da su masu matuƙar damuwa.

2.3 Rufin da ke Juriya da Lalacewa

Kayan Aiki: Tungsten carbide (HRC ≥60)

Ayyuka: Yana rage lalacewar bututu da kashi 50% a cikin rijiyoyin kwance.

Yana ƙara ƙarfin gogayya don daidaita igiyar haƙa rami da kuma sarrafa hanyar.

3. Ayyukan Muhimmi: Daga Rage Damuwa zuwa Kwanciyar Hankali

3.1 Rage Damuwa

Shaƙar Girgiza: Sassan da ke cikin damuwa da kayan roba suna canza rawar da ke cikin abin haƙa rami zuwa fitar da kuzarin roba.

Ƙarfin Karfi: Haɗaɗɗun kayan aiki masu tsawo suna sake rarraba damuwa na juyawa, suna rage gazawar gajiya a cikin bututun da aka saba.

3.2 Ingantaccen WOB

Amfanin NauyiNauyin matsakaici (misali, 38 kg/m ga φ89 mm HWDP) tsakanin bututun haƙa rami da abin wuya.

Sarrafa Mai Daidaitawa: Yana daidaita WOB don samuwar shale (yana hana bututun da ya makale) da kuma yadudduka masu tauri (yana inganta shigar ciki).

3.3 Tsarin Hanya da Ingancin Lafiya

Daidaiton Alƙawari: Haɗawa da ƙarfi yana rage girgizar igiyar haƙa rami, yana kiyaye hanyoyin rijiyoyin da aka tsara.

Hana Rushewa: Yana rage matsin lamba na gida daga lanƙwasawa, yayin da zagayawar laka ke tabbatar da tsaftar ramuka.

4. Aikace-aikacen Aiki

4.1 Haƙa Rijiya Mai Zurfi Mai Tsanani

Nazarin Shari'a: Rijiyar Tashen-1 (zurfin mita 8,408, >200°C, matsin lamba 140 MPa).

Aiki: Gauraye masu jure zafi mai yawa da ƙira masu lalacewa sun shawo kan tsarin lalata da matsin lamba na zagaye.

4.2 Kalubalen Yanayin Kasa

Muhalli na Iskar Gas Mai Tsami: Rijiyar Jiaoye-1HF (Filin Gas na Fuling Shale) ta yi amfani da ƙarfe da kuma rufin da ke jure tsatsa don yaƙar H₂S.

Rijiyoyin Hanya/Kwankwaso: HWDP mai nau'in karkace ya rage gogayya da kuma inganta sarrafa alkibla.

5. Ci gaban Fasaha

5.1 Sabbin Ƙirƙiro-ƙirƙiro Kan Masana'antu

Maganin Zafi: Kashewa da kuma rage zafi don inganta ƙarfin tasirin.

Tabbatar da Inganci: Gwajin Ultrasonic 100% (UT) da kuma duba barbashi na maganadisu (MPI).

5.2 Masana'antu Mai Wayo

Haɗin MES/ERP: Cikakken bin diddigin aiki daga oda zuwa isarwa.

Zaɓuɓɓukan Keɓancewa: Haɗin kafada biyu, manne mai ƙarfi, da kuma rufin filastik na ciki.

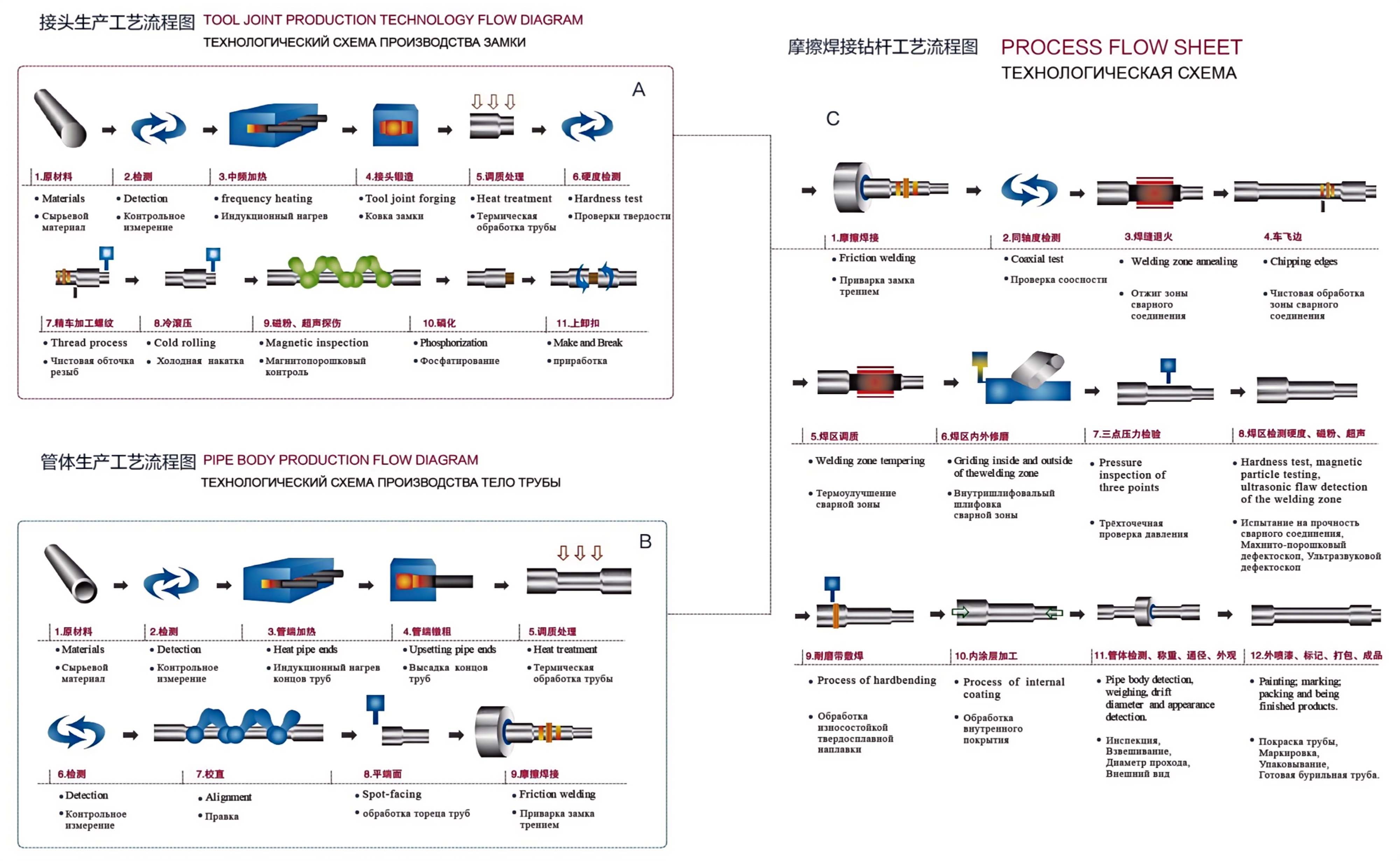

6. Tsarin Kera

Zaɓin Kayan Aiki: 4145H MOD ƙarfe masu ƙarfe.

Sarrafa Bututu: Hakowa → Ƙirƙirar da aka yi → Maganin zafi.

Ƙirƙirar Haɗin Kayan Aiki: Ƙirƙira → birgima mai sanyi → yin amfani da phosphating.

Walda/Haɗawa: Walda mai ƙarfi ko injin haɗaka.

Sarrafa Inganci: auna kauri na UT, gwajin tauri, tabbatar da matsin lamba.

Maganin Fuskar: Aiwatar da manne mai ƙarfi da kuma shafa mai hana tsatsa.

Kammalawa

A matsayin ginshiƙin fasahar haƙa rijiyoyin zamani, HWDP ta haɗa kirkire-kirkire na tsarin gine-gine da kimiyyar kayan aiki don haɓaka aminci da inganci na haƙa rijiyoyi. Daga rijiyoyi masu zurfi zuwa ga gurɓatattun abubuwa, rawar da take takawa a matsayin "canji mai sassauƙa" da "tallafi mai tsauri" tana ci gaba da tura iyakokin binciken mai da iskar gas.

Zaɓi Womic Steel Group a matsayin abokin tarayya mai aminci don bututun haƙa da kuma aikin isar da kaya mai ban mamaki. Barka da zuwa!

Yanar Gizo: www.womicsteel.com

Imel: sales@womicsteel.com

Waya/WhatsApp/WeChat: Victor: +86-15575100681 ko Jack: +86-18390957568

Lokacin Saƙo: Afrilu-11-2025