Maki na Kayan Aiki da Bin Ka'idojin Ƙasa da Ƙasa

Womic Steel yana samar da flanges na bakin karfe ta amfani da kayan masarufi masu inganci da aka samo daga masu samar da kayayyaki na duniya masu lasisi. Mafi yawan ma'aunin kayan sun haɗa da:

- Maki AISI/ASTM: 304, 304L, 304H, 316, 316L, 316Ti, 321, 317L, 310S, 904L

- Duplex & Super Duplex: S31803, S32205, S32750, S32760

- Alloys na Nickel (idan an buƙata): Alloy 20, Hastelloy C276, Inconel 625

Flanges ɗinmu na bakin ƙarfe sun dace da ƙa'idodin duniya kamar:

1. ASME/ANSI B16.5, B16.47 (Jerin A da B), B16.36, B16.48

2. ASTM A182 (An ƙirƙira), A240 (Farare), A351 (An ƙera)

3. EN 1092-1 / EN 1092-2

4. DIN 2631 zuwa DIN 2635

5. JIS B2220, BS 4504, GOST 33259, da ISO 7005

Womic Steel kuma na iya samar da flanges ga zane-zane na musamman na abokin ciniki da ƙayyadaddun aikin (OEM/ODM).

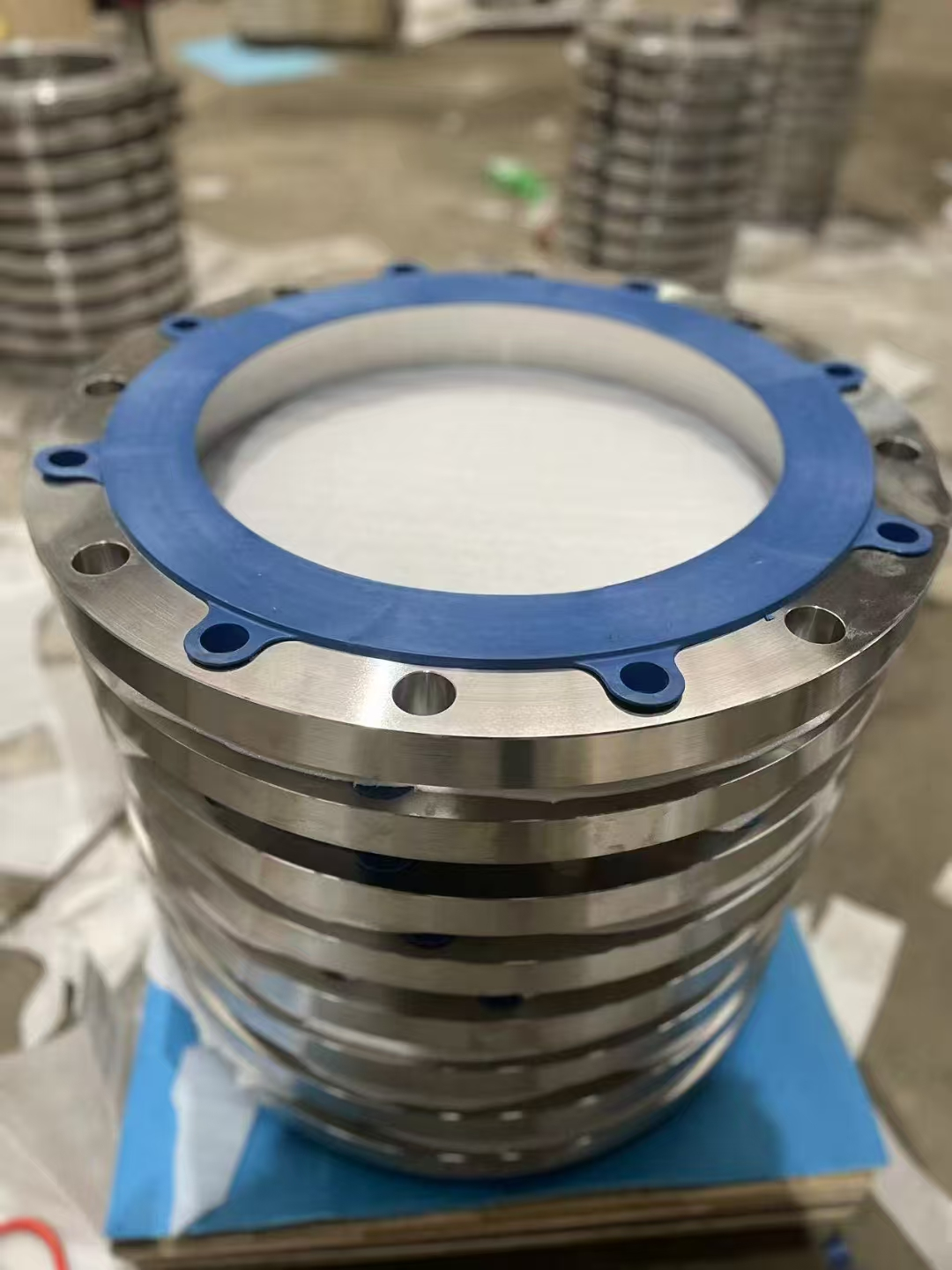

Nau'in Flange da Girman Range

Kamfanin Womic Steel yana kera nau'ikan flange na bakin karfe iri-iri, wadanda suka dace da azuzuwan matsin lamba tun daga aji 150 zuwa aji 2500 da kuma PN6 zuwa PN100.

Nau'in Flange da Aka Fi Sani:

1. Bututun Wuya na Weld (WN)

2. Zamewa-On Flange (SO)

3. Buɗaɗɗen Flange (BL)

4. Flange na Socket Weld (SW)

5. Flange mai zare (TH)

6. Flange na haɗin gwiwa (LJ)

7. Flange na Orifice, Dogon Wuya na Weld, Blind na Haske, Rage Flange

Girman Girma:

- ASME/ANSI: ½" zuwa 60"

- EN/DIN: DN10 zuwa DN1600

- Kauri: SCH10S zuwa SCH160 / XXS

- Injin da aka keɓance: har zuwa diamita na waje 120 "akwai

Bukatun Sinadarai da Inji (Misali: ASTM A182 F316L)

C ≤ 0.03, Mn ≤ 2.00, Si ≤ 1.00, Cr: 16.0–18.0, Ni: 10.0–14.0, Mo: 2.0–3.0

Duk kayan da ke shigowa ana gwada su ta hanyar gwajin PMI kuma ana tabbatar da cewa ana iya gano zafi a duk lokacin samarwa.

Kayayyakin Inji da Bukatun Tasiri

Womic Steel yana tabbatar da cewa kowane flange ya cika ko ya wuce ƙa'idodin injina bisa ga ƙayyadaddun ASTM ko EN:

- Ƙarfin Tashin Hankali: ≥ 485 MPa (F316L)

- Ƙarfin Yawa (kashi 0.2%): ≥ 170 MPa

- Tsawaitawa: ≥ 30%

- Tauri: ≤ 90 HRB

- Gwajin Tasirin Charpy V-Notch: Akwai a -20°C, -46°C, ko zafin jiki na musamman na aikin

Takaddun shaida na gwaji na injiniya na musamman (EN 10204 3.1 / 3.2) suna nan.

Tsarin Samarwa & Maganin Zafi

- Ƙirƙira - Sandunan da ba a iya amfani da su ba ko kuma billet da aka ƙera su da siffar injin hydraulic

2. Maganin Zafi - Daidaita ko rage yawan ruwan da ke cikin ruwan da aka tace ga kowane kayan aiki

3. Injin - Injin CNC yana tabbatar da lanƙwasa, haƙuri, da kuma rufe fuska (RF, RTJ, FF, MF, TG)

4. Hakowa - Da'irar ramin ƙugiya bisa ga ƙa'idar da aka saba ko ta abokin ciniki

5. Alamar - Laser ko an yi masa alama da sanyi da daraja, girma, lambar zafi, misali, da tambari

6. Pickling & Passivation - Yana tabbatar da juriya ga tsatsa da kuma tsaftace ƙarewaTsarin aiki na musamman na zaɓi: Rufin saman HVOF, gwajin cryogenic, ko walda mai rufewa yana samuwa idan an buƙata. Muna ba da kulawa ta musamman ga ƙaiƙayin fuska na rufewa (yawanci 3.2–6.3 μm Ra) don tabbatar da ingantaccen aikin gasket.

Gwaji & Kula da Inganci

Ana duba dukkan flanges ɗin gaba ɗaya tare da tsarin gwaji na mutum ɗaya (ITPs). Manyan gwaje-gwaje sun haɗa da:

- Dubawa da Dubawa (100%)

- Gwajin Hydrostatic (don haɗawa)

- PMI (Gano Kayan Aiki Mai Kyau)

- Gwajin Ultrasonic (UT) akan kayan aiki

- Gwajin Shigar Rini (PT)

- Gwajin Radiography (RT) idan an buƙata

- Gwajin Tauri da Tasiri

- Duba Taushin Fuskar

Cikakken bin diddigin bayanai tare da lambar zafi ta musamman da lambar batch ID.

Takaddun shaida

- ISO 9001:2015 Tsarin Gudanar da Inganci

- PED 2014/68/EU Umarnin Kayan Matsi (CE mai alama)

AD 2000-W0, EN 10204 3.1 / 3.2

- Takaddun shaida na DNV, BV, LR, ABS, da TÜV idan an buƙata

Duk kayan sun dace da NACE MR0175 / ISO 15156 idan ana buƙata don amfani da tsami.

Aikace-aikace

An ƙera flanges ɗin bakin ƙarfe na Womic Steel don:

- Bututun Mai da Iskar Gas

- Masana'antar mai da matatun mai

- Tashoshin Gyaran Ruwa

- Sarrafa Magunguna da Abinci

- Tashoshin Wutar Lantarki da Tsarin Boiler

- Shigar da Ruwa da na Ƙasashen Waje

- Tsarin Kashe Gobara, HVAC, da Tsarin Sanyaya GundumaDa sauransu.

Lokacin Gabatarwa da Marufi na Samarwa

Lokacin Gabatarwa:

- Kayayyakin ajiya: kwanaki 5-7

- Tsarin samarwa na yau da kullun: kwanaki 15-25

- Na musamman/an yi masa injina: Kwanaki 30-45 ya danganta da sarkakiyar aiki

Marufi:

- Kwandon plywood ko pallets masu dacewa da fitarwa a teku

- Murfin filastik don rufe fuskoki

- Naɗaɗɗen PE, mai tsaka tsaki, da jakunkunan busarwa don hana tsatsa

- Ana samun alamar barcode da pallet na mutum ɗaya

Jigilar Kayayyaki & Sufuri

Womic Steel tana ba da kyakkyawan tsarin jigilar kayayyaki da fa'idodin jigilar kaya:

- Cikewar akwati tare da mafi kyawun tsare-tsaren lodawa

- Isarwa zuwa wuraren da ake nufi da CIF/CFR/DDP

- Haɗin kai kai tsaye tare da layukan jigilar kaya yana tabbatar da ƙimar jigilar kaya mai kyau

- Marufi mai ƙarfi don manyan flanges tare da toshewa na ciki da sandunan ƙarfe

Ayyukan Keɓancewa & Sarrafawa

Aikin gyaran injin mu na cikin gida yana samar da:

- CNC juyi, fuska, da hakowa

- Injin gyaran fuska na musamman (RTJ, serrated, lebur)

- Walda da rufin rufi (ba tare da carbon ba)

- Zaren Zare (NPT/BSPT/BSPP)

- Zane-zane na musamman da tallafin CAD

- Gogewa da kuma sarrafa tsafta mai yawa don flanges na tsafta

- Maganin man shafawa da hana lalatawa

Me Yasa Zabi Womic Steel?

1. Sama da tan 15,000 na samar da kayayyaki a kowace shekara

2. Cikakken bayanin kayan aiki da kuma takardun dubawa

3. Sayen kayan masarufi cikin sauri daga masu hannun jari masu mahimmanci

4. Magani na musamman tare da gajeren lokacin jagora

5. Injin zamani da dakin gwaje-gwaje na cikin gida

6. Kwarewar fitar da kaya ta duniya da kuma nassoshi kan ayyukan

Tuntube Mu

Don aikinku na gaba, ku amince da Womic Steel don samar da flanges na bakin karfe masu inganci tare da isarwa cikin sauri da cikakken tallafin fasaha.

Yanar Gizo: www.womicsteel.com

Imel: sales@womicsteel.com

Waya/WhatsApp/WeChat: Victor: +86-15575100681 ko Jack: +86-18390957568

Lokacin Saƙo: Afrilu-19-2025