SLAG POT muhimmin sashi ne a cikin tsarin yin ƙarfe, wanda ake amfani da shi don hana da kuma cire slag. Womic Steel, babban kamfanin kera SLAG POTS, yana ba da kayayyaki masu inganci tare da ingantaccen aiki. Wannan labarin yana ba da cikakken bayani game da SLAG POT, yana mai da hankali kan tsarin samarwa, buƙatun fasaha, ƙarfin samar da Womic Steel, fa'idodi, da akwatunan fitarwa.

Womic Steel ta yi fice a matsayin fitaccen mai kera SLAG POTS, tana nuna kayan aikin samar da kayayyaki na zamani da kuma jajircewa wajen samar da inganci mara misaltuwa. Kayan aikinmu masu yawa sun haɗa da cranes masu ƙarfin ɗagawa na tan 260, tare da nau'ikan tanderu masu ƙarfin tan 5, tan 30, da tan 80. Bugu da ƙari, layin samar da mu yana da layin yashi na resin 20T/h, injin busar da tebur mai juyawa na tan 150, da kuma tanderu uku na CNC masu zafin jiki masu girman 12m×7m×5m, 8m×4m×3.5m, da 8m×4m×3.3m bi da bi. Muna da tsarin cire ƙurar tanderu mai ƙarfin murabba'in mita 30,000 da kayan aikin injina iri-iri kamar lathes na tsaye na 8m, 6.3m, da 5m, da kuma injunan niƙa guda 220 masu ban sha'awa da ban sha'awa.

Cibiyar gwajinmu ta musamman tana da kayan aikin dakin gwaje-gwaje na sinadarai, na'urar auna zafin jiki ta hanyar karatu kai tsaye, na'urar gwajin tensile mai nauyin tan 60, na'urar gwajin tasiri, na'urar gano lahani ta ultrasonic, na'urar gwajin taurin kai ta Rockwell, da na'urar hangen nesa ta ƙarfe, don tabbatar da ingantaccen iko a kowane mataki na samarwa.

Tare da sama da shekaru 20 na gwaninta a masana'antar siminti, Womic Steel tana da cibiyar haɓaka fasaha ta duniya da kuma ƙungiyar ƙwararrun masu fasaha. Kasancewar ta ƙware a samar da manyan kayayyakin ƙarfe na siminti da kuma manyan kayayyaki, tsarin samar da kayayyaki yana amfani da amfani da siminti na haɗin gwiwa, tare da fitarwa guda ɗaya ta siminti na kimanin tan 400, da kuma siminti na mutum ɗaya wanda ya kai tan 300. Kayayyakinmu suna samun aikace-aikace a masana'antu daban-daban, ciki har da haƙar siminti, gina jiragen ruwa, ƙera, aikin ƙarfe, injinan injiniya, gina hanyoyi da gada, kiyaye ruwa, da kuma samar da makamashin nukiliya, suna samar da simintin ƙarfe mai inganci na carbon da ƙarfe a cikin nau'ikan iri da ƙayyadaddun bayanai ga manyan masana'antun kera kayan aiki.

Kirkire-kirkire, inganci mai kyau, da kuma kyakkyawan sabis sune ginshiƙan falsafar kasuwancinmu. Ta hanyar ci gaba da ci gaban fasaha, mun ƙirƙiro samfuran ƙarfe da aka yi amfani da su sosai kamar SLAG POTS da ƙarfe ingot molds, waɗanda ake fitarwa zuwa ƙasashen duniya. POTS ɗinmu na SLAG POTS sun kama daga mita 3 cubic zuwa mita 45 cubic, tare da molds na ƙarfe ingot waɗanda nauyinsu ya kama daga tan 3.5 zuwa tan 175, duk sun cika manyan ƙa'idodin masana'antu. Mun kafa haɗin gwiwa na dogon lokaci tare da wasu shahararrun kamfanonin ƙarfe a duniya, ciki har da SMS Group a Jamus, POSCO a Koriya ta Kudu, da JFE a Japan, inda muka sami yabo daga abokan cinikin ƙasashen duniya.

A fannin samar da POTS na SLAG, Womic Steel ta jaddada kirkire-kirkire, tana amfani da hanyoyin ƙarfe na zamani da tsarin software don cimma zagayowar samarwa na kimanin kwanaki 40 a kowace tukunya. Tare da matsakaicin yawan amfani da shi sau 6000, POTS ɗinmu na SLAG sun wuce matsayin kasuwa a cikin dorewa da tsawon rai. Bugu da ƙari, ana jefa tukwanenmu a wuri ɗaya, wanda ke ƙara juriyar nakasa. Tare da zane-zanenku a hannu, Womic Steel na iya isar da simintin da kuke so mai inganci.

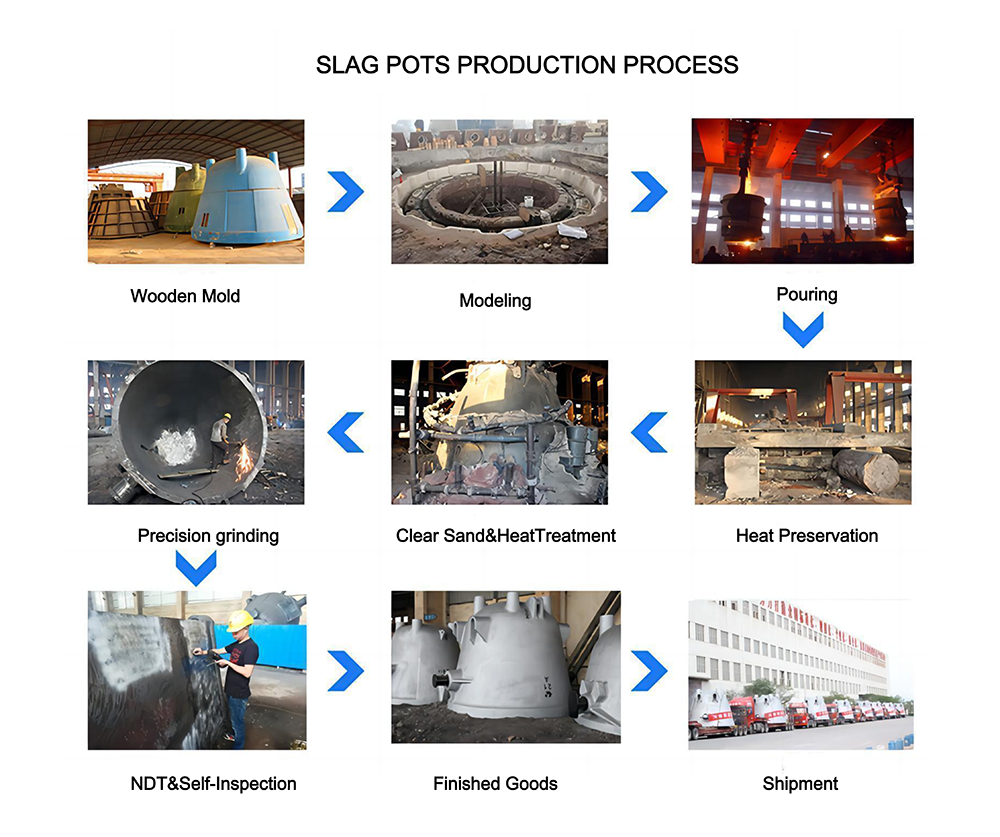

Kafin a yi amfani da siminti, muna kwaikwayon tsarin siminti ta amfani da manhajar CAE don yin nazari da kuma hasashen tsarin siminti da ingancin samfurin, tare da ci gaba da inganta tsarin simintin SLAG POT. Kayan aikinmu na ƙarfe mai cikakken inganci yana tabbatar da kyakkyawan sarrafa girman gabaɗaya, ta amfani da fasahar simintin yashi na sodium silicate don hana faruwar fashewar zafi a cikin simintin. Muna amfani da simintin rami, wanda yanayin ba ya shafar shi, yana tabbatar da ingantaccen samarwa.

A lokacin zubawa da kuma maganin zafi, muna narkar da kayan da aka duba a cikin tanderu mai siffar baka, muna nazarin ƙarfen da aka narke ta hanyar amfani da na'urar spectroscopy bayan an ɗauki samfur, sannan mu zuba shi bisa ga ƙa'idar "zubar da ruwa cikin sauri a ƙananan zafin jiki," muna rikodin lokacin zubawa da zafin jiki. Don magance babban bambanci a cikin abun da ke cikin carbon tsakanin ƙarfen ƙarfen kunne da kuma ƙarfen carbon na jikin tanki, mun ƙirƙiro cikakken tsari don sarrafa matsalolin walda sosai yayin samarwa.

Bayan an gama yin amfani da kayan wasan kwaikwayo, muna gudanar da ayyuka kamar yanke risers da burrs. Womic Steel tana da ƙwararrun ma'aikatan niƙa da kammalawa da manyan kayan aikin busar da harbe-harbe don inganta kyawun bayyanar POTS na SLAG, don cimma nasarar kammala saman da abokan ciniki ke buƙata. Haka kuma muna amfani da kayan aikin gwaji na zamani waɗanda ba sa lalatawa don yin gwaji mara lalatawa akan kowace POTS na SLAG don tabbatar da ingancinsa na ciki, tare da hana duk wani samfuri mai lahani barin masana'antar.

POTS na SLAG sune kayan aiki masu mahimmanci a cikin tsarin ƙera ƙarfe na kamfanonin ƙarfe. A Womic Steel, muna haɗa kirkire-kirkire da fasahar siminti ta ƙwararru da tsarin software, wanda ke rage zagayowar siminti na POTS na SLAG zuwa kimanin kwanaki 30. POTS ɗinmu na SLAG suna nuna juriya mai ƙarfi ta nakasa, suna tsawaita tsawon lokacin sabis ɗinsu idan aka kwatanta da matsayin kasuwa. Tare da zane-zanenku, za mu iya samar da siminti mai inganci da kuke buƙata.

Me Yasa Zabi Womic Steel?

1. Umarni daga International Giants: Muna karɓar oda sama da 100 na SLAG POTS na shekara-shekara daga shahararrun kamfanonin ƙarfe kamar Mittal Group, wanda hakan ya sa muka zama abokin hulɗarsu na dogon lokaci.

2. Ƙara Rayuwar Sabis: POTS ɗinmu na SLAG suna da tsawon rai na 20% idan aka kwatanta da matsayin kasuwa, tare da jinkirta gyaran farko da watanni 2-3 idan aka kwatanta da masu fafatawa.

3. Ma'aunin Dubawa na Mataki na 2: Muna amfani da kayan aikin gwaji na ƙwararru waɗanda ba sa lalatawa don tabbatar da cewa kowace SLAG POT ta cika ƙa'idar dubawa ta matakin ƙasa ta 2 ko takamaiman ƙa'idodin dubawa da abokan ciniki suka buƙata.

4. Keɓancewa ga Abokan Ciniki na Duniya: Babban samfurinmu na SLAG POT, wanda aka san shi da babban daidaitonsa, ana iya daidaita shi don biyan takamaiman buƙatun abokan ciniki a duk duniya. An yi nasarar fitar da samfuranmu zuwa ƙasashe da yankuna sama da 60, ciki har da Amurka, Mexico, Brazil, Indiya, Koriya ta Kudu, Japan, da Rasha.

Womic Steel tana bin ƙa'idodin samarwa masu tsauri, gami da GB/T 20878-200, ASTM A27/A27M, ASTM A297/A297M-20, ISO 4990:2015, BS EN 1561:2011, JIS G 5501:2018, DIN EN 1559, DIN 1681:2007-08, da sauransu... Tabbatar da inganci da aikin POTS na SLAG.

Tare da ƙarfin samar da tan 55,000 a kowace shekara da kuma bin ka'idojin tsarin kula da inganci na ƙasa na ISO 9001:2015, Womic Steel tana ba da tabbacin ingancin POTS ɗinmu na SLAG kuma tana tabbatar da isarwa akan lokaci. Mun sami yabo daga abokan cinikinmu da yawa saboda isar da kayanmu akan lokaci.

Ƙungiyarmu mai ƙwarewa tana ba da mafita na fasaha na ƙwararru waɗanda suka dace da takamaiman buƙatunku, suna tabbatar da samar da POTS masu inganci. Muna horar da ma'aikatanmu na gaba-gaba akai-akai don kiyaye ingantaccen ingancin samarwa.

Ku shiga sahun abokan ciniki masu gamsuwa waɗanda suka fuskanci inganci da sabis na musamman na Womic Steel. Tuntuɓe mu a yau don duk buƙatunku na SLAG POT.

Lokacin Saƙo: Maris-21-2024