Bakin ƙarfe shine taƙaitaccen bayani game da ƙarfe mai jure acid, iska, tururi, ruwa da sauran kafofin watsa labarai masu rauni na lalata ko kuma bakin ƙarfe ana kiransa bakin ƙarfe; kuma zai yi tsayayya da kafofin watsa labarai masu lalata sinadarai (acids, alkalis, gishiri, da sauran abubuwan da ke lalata sinadarai). Ana kiran tsatsa na ƙarfe ƙarfe mai jure acid.

Bakin ƙarfe yana nufin iska, tururi, ruwa da sauran ƙwayoyin cuta masu rauni da sinadarai masu lalata, alkalis, gishiri da sauran ƙwayoyin cuta masu lalata ƙarfe, wanda kuma aka sani da ƙarfe mai jure acid. A aikace, galibi ƙarfe mai jure lalata mai rauni wanda ake kira bakin ƙarfe, da kuma ƙarfe mai jure lalata mai guba wanda ake kira ƙarfe mai jure acid. Saboda bambance-bambancen da ke cikin sinadaran guda biyu, na farko ba lallai bane ya jure lalata mai guba, yayin da na biyun gabaɗaya ba shi da ƙarfi. Juriyar lalata mai guba na bakin ƙarfe ya dogara ne akan abubuwan da ke cikin ƙarfe.

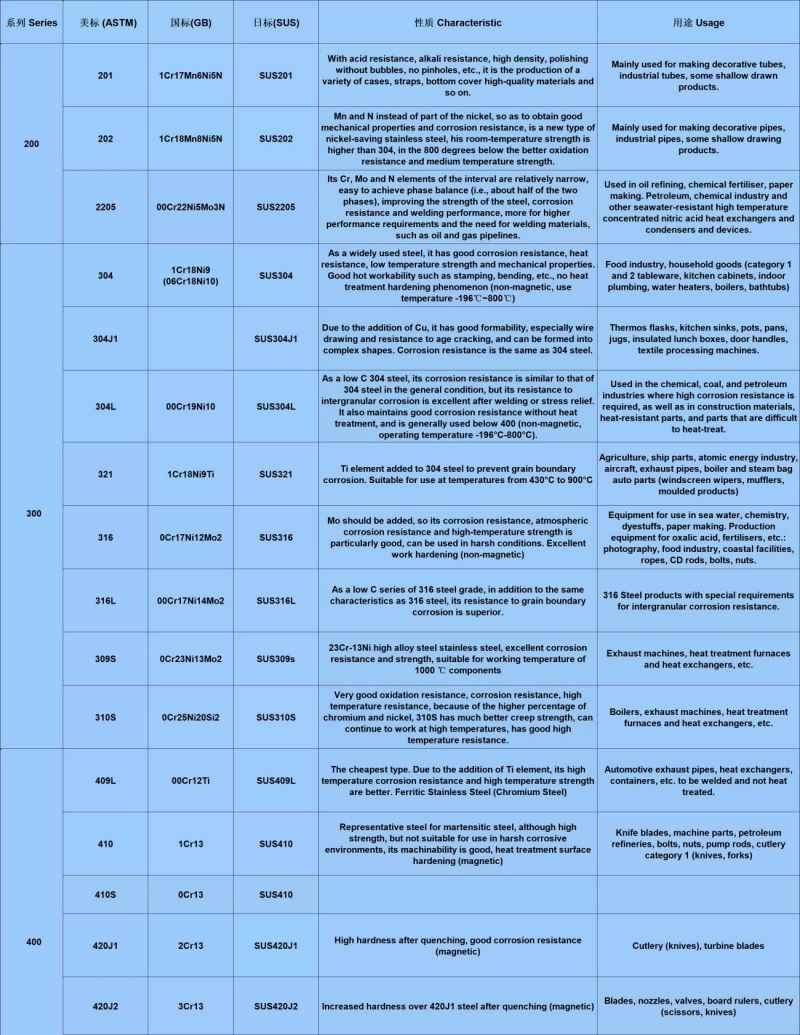

Rarrabawa gama gari

A cewar ƙungiyar ƙarfe

Gabaɗaya, bisa ga ƙungiyar ƙarfe, an raba ƙarfe na yau da kullun zuwa rukuni uku: ƙarfe na austenitic, ƙarfe na ferritic da ƙarfe na martensitic. Dangane da tsarin ƙarfe na waɗannan rukuni uku, ana samun ƙarfe na duplex, ƙarfe na bakin ciki mai taurarewa da kuma ƙarfe mai yawan ƙarfe wanda ke ɗauke da ƙasa da kashi 50% na ƙarfe don takamaiman buƙatu da dalilai.

1. Bakin ƙarfe na Austenitic

Tsarin matrix zuwa tsakiya mai siffar cubic crystal na austenitic organization (CY phase) yana mamaye da rashin maganadisu, galibi ta hanyar aiki mai sanyi don ƙarfafa shi (kuma yana iya haifar da wani matakin maganadisu) na bakin karfe. Cibiyar Iron and Steel ta Amurka ta yi amfani da jerin lakabin lambobi 200 da 300, kamar 304.

2. Ferritic bakin karfe

Tsarin matrix zuwa tsakiya na tsarin ferrite (wani lokaci) yana da rinjaye, yana da maganadisu, gabaɗaya ba za a iya taurare shi ta hanyar maganin zafi ba, amma aikin sanyi na iya sa ya ɗan ƙarfafa ƙarfe. Cibiyar Iron and Steel ta Amurka zuwa 430 da 446 don lakabin.

3. Bakin ƙarfe mai ƙarfi

Matrix ɗin yana da tsarin martensitic (mai siffar cubic ko cubic), mai maganadisu, ta hanyar maganin zafi zai iya daidaita halayen injiniyansa na bakin ƙarfe. Cibiyar Iron da Karfe ta Amurka zuwa lambobi 410, 420, da 440 masu alama. Martensite yana da tsarin austenitic a yanayin zafi mai yawa, wanda za'a iya canza shi zuwa martensite (watau taurare) lokacin da aka sanyaya shi zuwa zafin ɗaki a daidai gwargwado.

4. Bakin karfe irin Austenitic a ferrite (duplex)

Matrix ɗin yana da tsari mai matakai biyu na austenitic da ferrite, wanda abun cikin ƙaramin matakin matrix gabaɗaya ya fi 15%, magnetic, ana iya ƙarfafa shi ta hanyar aiki mai sanyi na bakin karfe, 329 ƙarfe ne na yau da kullun na bakin karfe mai duplex. Idan aka kwatanta da ƙarfe mai austenitic, ƙarfe mai ƙarfi, juriya ga tsatsa tsakanin granular da chloride damuwa ta tsatsa da tsatsa suna da kyau.

5. Ruwan sama mai taurare bakin karfe

Matrix ɗin tsari ne na austenitic ko martensitic, kuma ana iya taurare shi ta hanyar maganin taurarewar hazo don ya zama ƙarfe mai tauri. Cibiyar Iron and Steel ta Amurka zuwa jerin lakabin dijital 600, kamar 630, wato, 17-4PH.

Gabaɗaya, ban da ƙarfe mai ƙarfe mai ƙarfi, juriyar tsatsa ta bakin ƙarfe mai ƙarfi ta austenitic ta fi kyau, a cikin yanayi mara lalacewa, za ku iya amfani da ƙarfe mai ƙarfi, a cikin yanayi mai laushi, idan kayan yana buƙatar samun ƙarfi mai ƙarfi ko tauri mai ƙarfi, za ku iya amfani da ƙarfe mai ƙarfi na martensitic da ƙarfe mai tauri mai ƙarfi na hazo.

Halaye da Amfani

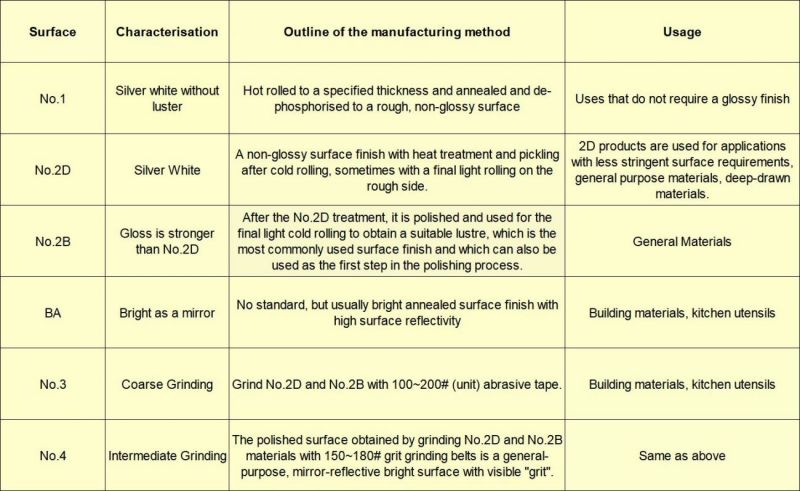

Tsarin saman

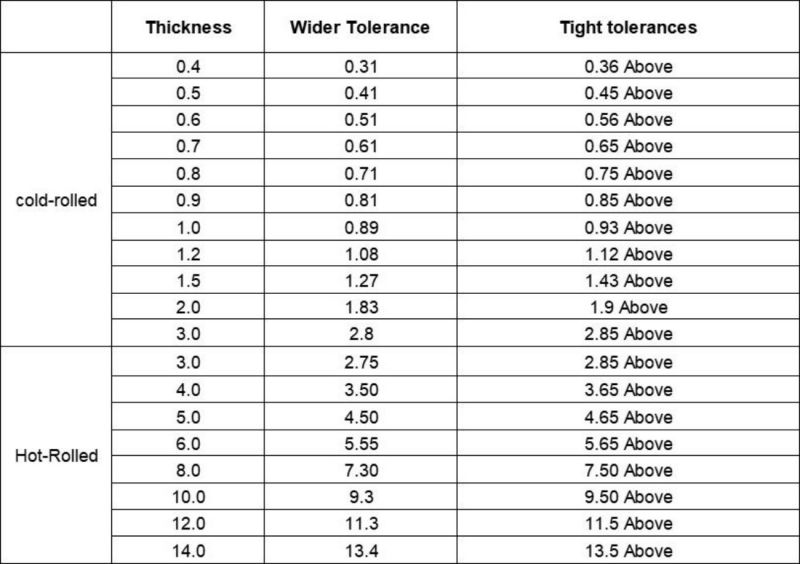

Bambancin kauri

1. Saboda injinan injin ƙarfe a lokacin birgima, ana dumama birgima ta hanyar ɗan canji, wanda ke haifar da jujjuyawar kauri na farantin, wanda gabaɗaya ya yi kauri a tsakiyar ɓangarorin biyu na siririn. A auna kauri na farantin, ya kamata a auna ƙa'idodin yanayin farantin a tsakiyar kan farantin.

2. Dalilin haƙurin ya dogara ne akan buƙatar kasuwa da abokan ciniki, gabaɗaya an raba su zuwa manyan da ƙananan haƙuri.

V. Bukatun masana'antu, dubawa

1. Farantin bututu

① haɗin bututun da aka haɗa da farantin bututu don duba hasken 100% ko UT, matakin cancanta: RT: Ⅱ UT: matakin Ⅰ;

② Baya ga bakin karfe, farantin bututu mai laushi mai sauƙin magance zafi;

③ Faɗin ramin ramin bututun bututu: bisa ga dabarar lissafin faɗin gadar ramin: B = (S - d) - D1

Mafi ƙarancin faɗin gadar ramin: B = 1/2 (S - d) + C;

2. Maganin zafi na akwatin bututu:

Karfe mai carbon, ƙaramin ƙarfe mai ƙarfe mai kauri da aka haɗa da ɓangaren bututun da aka raba, da kuma akwatin bututun buɗewa na gefe fiye da 1/3 na diamita na ciki na akwatin bututun silinda, a cikin aikace-aikacen walda don rage damuwa don maganin zafi, ya kamata a sarrafa saman rufewa da flange bayan maganin zafi.

3. Gwajin Matsi

Lokacin da matsin lamba na ƙirar harsashi ya fi ƙasa da matsin lamba na tsarin bututu, don duba ingancin bututun musayar zafi da haɗin farantin bututu

① Matsin lamba na shirin harsashi don ƙara matsin lamba na gwaji tare da shirin bututun daidai da gwajin hydraulic, don duba ko kwararar haɗin bututun ya faru. (Duk da haka, ya zama dole a tabbatar da cewa babban matsin lamba na harsashi yayin gwajin hydraulic shine ≤0.9ReLΦ)

② Idan hanyar da ke sama ba ta dace ba, harsashin zai iya zama gwajin hydrostatic bisa ga matsin lamba na asali bayan wucewa, sannan harsashin don gwajin zubar da ammonia ko gwajin zubar da halogen.

Wane irin bakin karfe ne ba ya da sauƙin tsatsa?

Akwai manyan abubuwa guda uku da ke shafar tsatsar bakin karfe:

1. Abubuwan da ke cikin abubuwan da ke haɗa ƙarfe. Gabaɗaya, abubuwan da ke cikin chromium a cikin ƙarfe 10.5% ba su da sauƙin tsatsa. Mafi girman abubuwan da ke cikin chromium da nickel sun fi kyau, kamar su 304 nickel na abu 85 ~ 10%, chromium na 18% ~ 20%, irin wannan bakin ƙarfe gabaɗaya ba tsatsa ba ne.

2. Tsarin narkewar ƙarfe na masana'anta zai kuma shafi juriyar tsatsa na bakin ƙarfe. Fasahar narkewa tana da kyau, kayan aiki na zamani, fasahar zamani, babban injin ƙarfe na bakin ƙarfe duka a cikin sarrafa abubuwan haɗa sinadarai, cire ƙazanta, sarrafa zafin jiki na billet ana iya tabbatar da shi, don haka ingancin samfurin yana da karko kuma abin dogaro, inganci mai kyau, ba mai sauƙin tsatsa ba. Akasin haka, wasu ƙananan kayan aikin injin ƙarfe na baya, fasahar baya, tsarin narkewa, da ƙazanta ba za a iya cire su ba, samar da kayayyaki zai zama tsatsa ba makawa.

3. Muhalli na waje. Muhalli busasshe da iska ba shi da sauƙin tsatsa, yayin da danshi na iska, yanayin ruwan sama mai ci gaba, ko iska mai ɗauke da acidity da alkalinity na muhalli yana da sauƙin tsatsa. 304 kayan ƙarfe na bakin ƙarfe, idan muhallin da ke kewaye ya yi rauni sosai shi ma yana da tsatsa.

Tabo na tsatsa na bakin karfe yadda za a magance su?

1. Hanyar Sinadarai

Da man shafawa ko feshi don taimakawa sassan da suka yi tsatsa don sake farfaɗo da samuwar fim ɗin chromium oxide don dawo da juriyar tsatsa, bayan an cire shi, domin cire duk wani gurɓataccen abu da ragowar acid, yana da matuƙar muhimmanci a yi kurkure da ruwa yadda ya kamata. Bayan an sarrafa komai kuma an sake goge shi da kayan aikin gogewa, ana iya rufe shi da kakin gogewa. Ga ƙananan wuraren tsatsa na gida kuma ana iya amfani da man fetur 1: 1, ana iya amfani da cakuda mai da tsumma mai tsabta don goge wuraren tsatsa.

2. Hanyoyin injiniya

Tsaftace yashi, tsaftacewa da gilashin ko barbashi na yumbu, gogewa, gogewa da gogewa. Hanyoyin injiniya suna da damar goge gurɓataccen abu da kayan da aka cire a baya, kayan gogewa ko kayan da aka goge suka haifar. Duk wani gurɓataccen abu, musamman barbashi na baƙin ƙarfe na ƙasashen waje, na iya zama tushen tsatsa, musamman a cikin yanayi mai danshi. Saboda haka, ya kamata a tsaftace saman da aka tsaftace ta hanyar injiniya a ƙarƙashin yanayi na bushewa. Amfani da hanyoyin injiniya yana tsaftace samansa kawai kuma baya canza juriyar tsatsa na kayan da kansa. Saboda haka, ana ba da shawarar a sake goge saman da kayan gogewa sannan a rufe shi da kakin gogewa bayan tsaftacewa ta injiniya.

Kayan aiki da aka saba amfani da su a matsayin maki da kaddarorin bakin karfe

1.304 bakin karfe. Yana ɗaya daga cikin ƙarfen austenitic mai amfani da yawa kuma ana amfani da shi sosai, ya dace da ƙera sassan ƙera abubuwa masu zurfi da bututun acid, kwantena, sassan gini, nau'ikan kayan aiki daban-daban, da sauransu. Hakanan yana iya ƙera kayan aiki da sassa marasa maganadisu, masu ƙarancin zafin jiki.

Karfe mai nauyin lita 2.304 na bakin karfe. Domin magance matsalar ruwan sama na Cr23C6 da bakin karfe 304 ke haifarwa a wasu yanayi, akwai babban yanayin tsatsa tsakanin granular da kuma ci gaban bakin karfe mai ƙarancin carbon austenitic, yanayin juriyar tsatsa tsakanin granular ya fi na bakin karfe 304 kyau. Baya ga ɗan ƙaramin ƙarfi, sauran kaddarorin da ke da bakin karfe 321, waɗanda galibi ake amfani da su don kayan aiki masu jure tsatsa da abubuwan da ke cikin su, ba za a iya amfani da su don yin maganin mafita na walda ba, don ƙera nau'ikan kayan aiki daban-daban.

Bakin ƙarfe 3.304H. Reshen ciki na bakin ƙarfe 304, rabon yawan carbon a cikin 0.04% ~ 0.10%, aikin zafin jiki mai yawa ya fi ƙarfe 304 na bakin ƙarfe.

4.316 bakin karfe. A cikin ƙarfe 10Cr18Ni12 bisa ga ƙarin molybdenum, don haka ƙarfen yana da kyakkyawan juriya ga rage watsawa da juriyar tsatsa. A cikin ruwan teku da sauran kafofin watsa labarai, juriyar tsatsa ta fi ƙarfe 304 bakin karfe, wanda galibi ana amfani da shi don kayan da ke jure tsatsa.

Bakin ƙarfe mai nauyin lita 5.316. Karfe mai ƙarancin carbon sosai, mai juriya ga tsatsa mai kama da juna, wanda ya dace da ƙera sassan da kayan aiki masu kauri, kamar kayan aikin petrochemical a cikin kayan da ke jure tsatsa.

Bakin ƙarfe 6.316H. reshen ciki na bakin ƙarfe 316, ƙashin nauyin carbon na 0.04%-0.10%, aikin zafin jiki mai yawa ya fi bakin ƙarfe 316 kyau.

7.317 bakin karfe. Rage tsatsa da juriyar rarrafe ya fi ƙarfe 316L bakin karfe, wanda ake amfani da shi wajen kera kayan aikin da ke jure lalata sinadarai da sinadarai masu guba.

8.321 bakin karfe. An daidaita ƙarfe mai ƙarfi na titanium, wanda aka ƙara titanium don inganta juriyar tsatsa tsakanin granular, kuma yana da kyawawan halaye na injiniya masu zafi, ana iya maye gurbinsa da ƙarfe mai ƙarancin carbon austenitic. Baya ga juriyar tsatsa mai zafi ko hydrogen da sauran lokatai na musamman, ba a ba da shawarar yanayin gabaɗaya ba.

9.347 bakin karfe. An ƙara niobium don inganta juriya ga tsatsa tsakanin granular, juriya ga tsatsa a cikin acid, alkali, gishiri da sauran hanyoyin lalata tare da bakin karfe 321, ingantaccen aikin walda, ana iya amfani da shi azaman kayan da ke jure tsatsa da ƙarfe mai jure zafi wanda aka fi amfani da shi don wutar lantarki ta zafi, filayen mai, kamar samar da kwantena, bututun mai, masu musayar zafi, shafts, tanderun masana'antu a cikin bututun mai da ma'aunin zafi na bututun mai da sauransu.

Karfe mai girman lita 10.904. Karfe mai girman lita 10.904 mai cikakken ƙarfi, wani ƙarfe mai girman lita 10 na bakin austenitic wanda Finland Otto Kemp ta ƙirƙiro, ɓangaren yawan nickel ɗinsa na kashi 24% zuwa 26%, ɓangaren yawan carbon da bai kai kashi 0.02% ba, kyakkyawan juriya ga tsatsa, a cikin acid ɗin da ba sa yin oxidizing kamar sulfuric, acetic, formic da phosphoric acid yana da juriya ga tsatsa, kuma a lokaci guda yana da juriya ga tsatsa mai kauri da juriya ga tsatsa mai ƙarfi. Ya dace da yawan sinadarin sulfuric acid da ke ƙasa da digiri 70, kuma yana da juriya ga tsatsa mai kyau ga acetic acid da gaurayen acid na formic acid da acetic acid na kowane taro da kowane zafin jiki a ƙarƙashin matsin lamba na al'ada. Asalin ma'aunin ASMESB-625 ya danganta shi da ƙarfe mai tushen nickel, kuma sabon ma'aunin ya danganta shi da ƙarfe mai kauri. China kimanin ƙarfe 015Cr19Ni26Mo5Cu2 ne kawai, wasu daga cikin masana'antun kayan aikin Turai suna amfani da mahimman kayan aiki ta amfani da bakin ƙarfe 904L, kamar bututun auna ma'aunin kwararar ruwa na E + H. Ana amfani da bakin ƙarfe 904L, akwatin agogon Rolex kuma ana amfani da bakin ƙarfe 904L.

Bakin karfe 11.440C. Bakin karfe mai Martensitic, bakin karfe mai tauri, bakin karfe mai tauri mafi girman tauri, tauri HRC57. Ana amfani da shi sosai wajen samar da bututun ƙarfe, bearings, bawuloli, spools na bawul, kujerun bawul, hannayen riga, tushen bawul, da sauransu.

Bakin ƙarfe mai tsawon 12.17-4PH. Bakin ƙarfe mai taurarewa mai ƙarfi, HRC44, mai ƙarfi, tauri da juriyar tsatsa, ba za a iya amfani da shi ba a yanayin zafi sama da 300 ℃. Yana da juriya mai kyau ga tsatsa ko acid mai narkewa a yanayi da gishiri, kuma juriyarsa ta tsatsa iri ɗaya ce da ta ƙarfe mai tsawon 304 da ƙarfe mai tsawon 430, wanda ake amfani da shi wajen kera dandamali na teku, ruwan wukake na turbine, spools, kujeru, hannayen riga da kuma tushen bawuloli.

A cikin sana'ar kayan aiki, tare da batutuwan gabaɗaya da farashi, zaɓin ƙarfe na austenitic na yau da kullun shine 304-304L-316-316L-317-321-347-904L bakin ƙarfe, wanda 317 ba a saba amfani da shi ba, 321 ba a ba da shawarar ba, 347 ana amfani da shi don tsatsa mai zafi mai zafi, 904L kawai kayan asali ne na wasu sassan masana'antun daban-daban, ƙirar ba za ta ɗauki matakin zaɓar 904L ba.

A cikin zaɓin ƙirar kayan aiki, yawanci za a sami kayan aikin kayan aiki da kayan bututu lokatai daban-daban, musamman a cikin yanayin zafi mai zafi, dole ne mu kula da zaɓin kayan aikin kayan aiki don saduwa da kayan aikin tsari ko zafin jiki da matsin lamba na ƙirar bututun, kamar bututun ƙarfe mai zafi na chrome molybdenum, yayin da kayan aikin don zaɓar ƙarfe mai bakin ƙarfe, to yana da yuwuwar zama matsala, dole ne ku je ku tuntuɓi ma'aunin zafin jiki da matsin lamba na kayan da suka dace.

A cikin zaɓin ƙirar kayan aiki, sau da yawa ana fuskantar nau'ikan tsarin daban-daban, jerin, maki na bakin karfe, zaɓin ya kamata ya dogara ne akan takamaiman hanyoyin aiki, zafin jiki, matsin lamba, sassan da aka jaddada, lalata da farashi da sauran ra'ayoyi.

Lokacin Saƙo: Oktoba-11-2023