1. Bayanin Samfuri

An ƙera kwalbar ƙarfe bisa gaASTM A27 Grade 70-36simintin ƙarfe ne mai nauyi wanda aka ƙera don sarrafawa, jigilar kaya, da kuma riƙe na ɗan lokaci na narkakken tarkacen ƙarfe ko kayan zafi a aikace-aikacen ƙarfe da masana'antu.

An zaɓi wannan matakin musamman don samar da daidaito mafi kyau tsakaninƙarfi, juriya, da juriya ga matsin lamba na zafi da na inji, wanda hakan ya sa ya dace musamman ga layukan da ake yawan ɗagawa, zagayowar zafi, da kuma nauyin buguwa.

2. Ma'aunin da ya dace

ASTM A27 / A27M– Simintin Karfe, Carbon, don Amfani Gabaɗaya

Kayan Aiki:ASTM A27 Grade 70-36

Za a samar da dukkan kayan da aka yi amfani da su, a gwada su, sannan a duba su bisa ga ka'idojin ASTM A27 sai dai idan mai siye ya ƙayyade wani abu daban.

3. Halayen Kayan Aiki - ASTM A27 Grade 70-36

ASTM A27 Grade 70-36 wani siminti ne mai matsakaicin ƙarfi na ƙarfe mai kama da ƙarfe wanda aka san shi da kyakkyawan filastik da amincin tsari.

3.1 Halayen Inji (Mafi ƙaranci)

| Kadara | Bukatar |

| Ƙarfin Taurin Kai | ≥ 70,000 psi (≈ 485 MPa) |

| Ƙarfin Ba da Kyauta | ≥ 36,000 psi (≈ 250 MPa) |

| Tsawaita (a cikin inci 2 / 50 mm) | ≥ 22% |

| Rage Yanki | ≥ 30% |

Waɗannan halayen injiniya suna tabbatar da isasshen ƙarfin ɗaukar kaya yayin da suke riƙe da kyakkyawan juriya ga fashewa da karyewar karyewa.

3.2 Haɗaɗɗen Sinadarai (Iyakokin Yau da Kullum)

| Sinadarin | Matsakaicin abun ciki |

| Carbon (C) | ≤ 0.35% |

| Manganese (Mn) | ≤ 0.70% |

| Phosphorus (P) | ≤ 0.05% |

| Sulfur (S) | ≤ 0.06% |

Abubuwan da ke cikin carbon da manganese da aka sarrafa suna taimakawa wajen tabbatar da ingancin simintin da kuma ingantaccen aikin injiniya ba tare da buƙatar abubuwan da ke haɗa ƙarfe ba.

4. Tsarin Zane da Siffofin Tsarin Ladle

l Jiki mai sassaka guda ɗaya ko jikin siminti tare da ƙugiya masu ɗagawa / kayan ɗagawa

l Tsarin lissafi mai santsi don rage yawan damuwa

l Isasshen kauri na bango wanda aka tsara don jure yanayin zafi da nauyin sarrafa injina

l Maki na ɗagawa an tsara su bisa ga yanayin ɗagawa mai cikakken kaya, gami da abubuwan aminci

Tsarin ladle yana jaddadamutuncin tsarin da dorewar sabis, musamman a lokacin da ake fuskantar zafi mai yawa da kuma maimaita sarrafa crane.

5. Tsarin Kera

5.1 Hanyar Yin Zane

l Simintin yashi ta amfani da kayan gyare-gyaren da aka sarrafa waɗanda suka dace da manyan sassan simintin ƙarfe

l Ana ba da shawarar simintin zafi guda ɗaya don tabbatar da daidaiton sinadarai

5.2 Narkewa da Zubawa

l Tanderun baka na lantarki (EAF) ko tanderun shigarwa

l Tsananin iko kan sinadaran da ke cikinsa kafin a zuba

l Zafin zubar da ruwa mai sarrafawa don rage lahani na ciki

5.3 Maganin Zafi

Daidaita maganin zafiyawanci ana amfani da shi

Manufa:

l Tsarin hatsi mai tsaftacewa

l Inganta tauri da kuma daidaiton kayan aikin injiniya

l Rage matsin lamba na simintin ciki

Za a rubuta sigogin maganin zafi kuma a iya gano su.

6. Kulawa da Dubawa Mai Inganci

6.1 Nazarin Sinadarai

l An gudanar da bincike mai zafi ga kowane narke

Sakamakon da aka rubuta a cikin Takaddun Shaidar Gwaji na Mill (MTC)

6.2 Gwajin Inji

l Gwada takardun shaida da aka yi daga wuta iri ɗaya da aka yi wa magani da zafi tare da cokali mai yatsu:

Gwajin tensile

l Tabbatar da ƙarfin samarwa

l Ƙarawa da rage yankin

6.3 Jarrabawar da Ba Ta Da Lalacewa Ba (kamar yadda ya dace)

Dangane da buƙatun aikin:

l Dubawar gani (100%)

Gwajin Magnetic Barbashi (MT) don fasa saman

l Gwajin Ultrasonic (UT) don ingantaccen sauti na ciki

6.4 Duba Girma

l Tabbatarwa akan zane-zanen da aka amince da su

l Kulawa ta musamman ga ɗaga ƙugiya da kuma sassan ɗaukar nauyi masu mahimmanci

7. Takardu da Takaddun shaida

Ana bayar da waɗannan takardu masu zuwa:

Takardar Shaidar Gwaji ta Mill (EN 10204 3.1 ko makamancin haka)

Rahoton sinadaran abun da ke ciki

l Sakamakon gwajin injina

l Rikodin maganin zafi

l Rahotannin NDT (idan ana buƙata)

l Rahoton dubawa mai girma

Ana iya gano duk takardu zuwa ga tsarin zafi da jefawa daidai.

8. Faɗin Aikace-aikace

Ana amfani da manyan kwandunan ƙarfe da aka samar bisa ga ASTM A27 Grade 70-36 a fannoni da dama:

l Masana'antar ƙarfe da masana'antar ƙarfe

l tsarin sarrafa Slag

l Bita na aikin ƙarfe

l Ayyukan canja wurin kayan masana'antu masu nauyi

Wannan matakin ya dace musamman ga aikace-aikace indaductility da aminci a ƙarƙashin nauyin aiki mai ƙarfisuna da mahimmanci.

9. Fa'idodin Amfani da ASTM A27 Grade 70-36 don Ladles

l Madalla da daidaito tsakanin ƙarfi da ductility

l Rage haɗarin karyewar karyewa a ƙarƙashin girgizar zafi

l Inganci mai inganci idan aka kwatanta da ƙarfi mafi girma, ƙarancin juriya

l Tabbatar da aminci ga aikace-aikacen simintin nauyi

Karɓar masu dubawa da kamfanonin injiniya ya yi yawa

Bayanin Marufi & Sufuri

Shawarar NCM (Lambar Haraji):8454100000

Nau'in Marufi da Aka Yi Amfani da Shi:

An gina wani akwati na musamman na katako don jigilar ruwa.

Fim ɗin hana tsatsa ko kuma fim ɗin hana tsatsa da aka shafa a saman.

A ɗaure mashi da madaurin ƙarfe da kuma toshe itace don guje wa motsi yayin jigilar kaya.

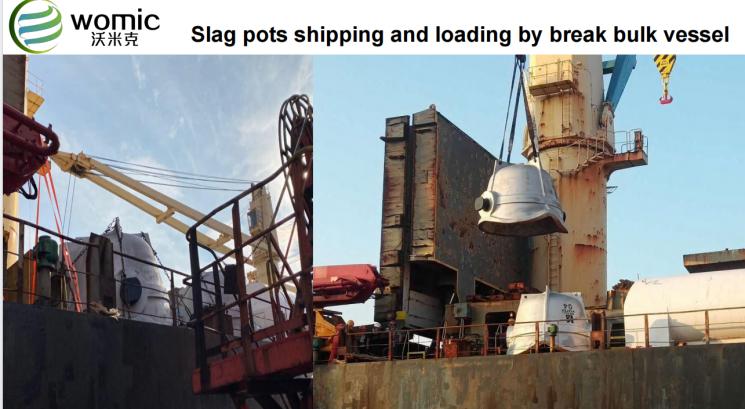

Nau'in hanyoyin jigilar kaya:Akwati,babban jirgin ruwa:

Akwatin Raki Mai Faɗi- An fi so don sauƙin lodawa/saukewa da crane.

Buɗe Akwatin Sama- Ana amfani da shi lokacin da aka yi amfani da shi a tsaye.

Jirgin Ruwa Mai Yawa- Ga babban girman ba za a iya ɗora shi cikin kwantena ba

Kuna buƙatar Lasisin Sufuri na Gida?

Eh, saboda girman tukwanen,lasisin sufuri na musammanYawanci ana buƙatar sayayya ta hanya ko layin dogo. Ana iya samar da takardu da zane-zane na fasaha don taimakawa wajen neman izini.

Idan akwai kaya na musamman da ya yi yawa, wane irin kayan aiki za a yi amfani da shi don sarrafawa?

Crawnerstare da isasshen ƙarfin da zai iya ɗaukar ƙananan girma da nauyi.

Giraben bakin tekudon tukwane masu nauyin sama da tan 28

An ƙera dukkan wuraren ɗagawa kuma an gwada su don tabbatar da aminci da bin ƙa'idodin sarrafawa.

10. Kammalawa

ASTM A27 Grade 70-36 zaɓi ne mai inganci kuma mai inganci a fannin tattalin arziki ga kwalban ƙarfe da ake amfani da su a cikin mawuyacin yanayi na masana'antu. Halayen injinan sa, tare da sinadarai masu sarrafawa da kuma ingantaccen maganin zafi, suna ba da aminci da aminci na dogon lokaci a aiki.

Muna alfahari da kanmu a matsayinmuayyukan keɓancewa, saurin samar da da'ira, kumahanyar sadarwar isar da sako ta duniya, tabbatar da cewa an biya buƙatunku na musamman da daidaito da inganci.

Yanar Gizo: www.womicsteel.com

Imel: sales@womicsteel.com

Waya/WhatsApp/WeChat: Victor: +86-15575100681 ko Jack: +86-18390957568

Lokacin Saƙo: Janairu-22-2026