Bayanin Samfuri

Womic Steel babbar masana'anta ce ta musammanEN 10305- bututun ƙarfe marasa sumul, waɗanda aka ƙera don daidaito, ƙarfi, da dorewa a fannoni daban-daban na masana'antu. An ƙera bututun ƙarfe marasa sumul ɗinmu don cika ƙa'idodin ƙasashen duniya mafi tsauri, suna ba da ingantaccen aiki ga tsarin jigilar injina, tsari, da ruwa. Daga injiniyan motoci zuwa silinda na hydraulic, Womic Steel yana tabbatar da cewa an ƙera kowane bututu don inganci, yana tabbatar da inganci da aminci na musamman.

NamuTS EN 10305 bututun ƙarfe marasa tsarisun dace da aikace-aikacen ƙarfi mai ƙarfi waɗanda ke buƙatar ma'auni daidai, kyawawan halayen injiniya, da juriya mai ƙarfi ga lalacewa da tsatsa. Ana amfani da waɗannan bututun a fannoni daban-daban, ciki har da motoci, injina, jigilar ruwa, da injiniyan injiniya, suna samar da ingantattun mafita don aikace-aikacen injiniyan daidai.

Tsarin Samar da Bututun Karfe na EN 10305

Masana'antun ƙarfe na WomicTS EN 10305 bututun ƙarfe marasa tsaria cikin girma dabam-dabam da girma dabam-dabam, wanda ke tabbatar da sauƙin amfani ga aikace-aikace daban-daban. Jerin samarwa na yau da kullun ya haɗa da:

- Diamita na Waje (OD)Girman: 6mm zuwa 406mm

- Kauri a Bango (WT)Girman: 1mm zuwa 18mm

- Tsawon: Tsawon da aka keɓance, yawanci daga mita 6 zuwa mita 12, ana iya samu akan buƙatar abokin ciniki.

Ana iya samar da waɗannan bututun tare da takamaiman buƙatu don diamita na musamman, tsayi, da kauri na bango bisa ga ƙayyadaddun buƙatun abokin ciniki da buƙatun aikin.

EN 10305 Juriyar Bututun Karfe Mara Sumul

Kamfanin Womic SteelTS EN 10305 bututun ƙarfe marasa tsarian ƙera su ne da mai da hankali kan daidaito. Muna ba da garantin haƙuri mai zuwa ga samfuranmu

| Sigogi | Haƙuri |

| Diamita na Waje (OD) | ± 0.01 mm |

| Kauri a Bango (WT) | ± 0.1 mm |

| Ovality (Ovalness) | 0.1 mm |

| Tsawon | ± 5 mm |

| Daidaito | Matsakaicin 0.5 mm a kowace mita |

| Ƙarshen Fuskar | Kamar yadda aka saba ga abokin ciniki (yawanci: Man hana tsatsa, Rufin Chrome Mai Tauri, Rufin Nickel Chromium, ko wasu rufi) |

| Murabba'in Ƙarshe | ± 1° |

EN 10305 Bututun Karfe Mara Sumul Yanayin Isarwa

Ana yin bututun ta amfani dazane mai sanyikobirgima cikin sanyihanyoyin da ake bayarwa kuma ana bayar da su a cikin yanayi daban-daban na isarwa bisa ga takamaiman buƙatun abokin ciniki. Waɗannan sun haɗa da:

Tebur 1 — Sharuɗɗan isarwa

| Naɗi | Alamara | Bayani |

| An yi masa sanyi / mai tauri | +C | Babu maganin zafi na ƙarshe bayan zane na sanyi na ƙarshe. |

| Sanyi mai jan hankali / mai laushi | +LC | Ana bin maganin zafi na ƙarshe da zane mai dacewa wucewa (ƙayyadadden raguwar yanki). |

| Sanyi ya jawo kuma an rage damuwa | +SR | Bayan an gama yin sanyi, ana rage damuwa a cikin yanayin da aka tsara. |

| Mai laushi mai laushi | +A | Bayan an gama yin amfani da injin, ana sanya bututun a cikin wuri mai sanyi da iska mai kyau. |

| An daidaita | +N | Bayan an gama yin sanyi, ana daidaita bututun a cikin tsari mai sauƙi yanayi mai sarrafawa. |

| a: Daidai da EN10027–1. | ||

Tsarin Sinadaran TSAMI NA EN 10305 Bututun Karfe Mara Sumul

TheEN 10305Ana samar da bututun ne daga ingancin ƙarfe mai inganci. A ƙasa akwai taƙaitaccen bayani game da ma'aunin kayan da aka saba amfani da su da kuma sinadaran da ke cikinsu:

Tebur na 2 — Haɗin sinadarai (binciken siminti)

| Karfe aji | % ta hanyar taro | ||||||

| Sunan ƙarfe | Karfe | C | Si | Mn | P | Sa | Aljimillab |

| lamba | |||||||

| E215 | 1.0212 | 0,10 | 0,05 | 0,70 | 0,025 | 0,025 | 0,025 |

| E235 | 1.0308 | 0,17 | 0,35 | 1,20 | 0,025 | 0,025 | 0,015 |

| E355 | 1.0580 | 0,22 | 0,55 | 1,60 | 0,025 | 0,025 | 0,020 |

| Abubuwan da ba a ambata a cikin wannan tebur ba (amma duba bayanin kulab) ba za a ƙara shi da gangan ba a cikin ƙarfe ba tare da amincewar mai siye ba, sai dai abubuwan da za a iya ƙarawa don dalilai na deoxidation da/ko ɗaure nitrogen. Za a ɗauki duk matakan da suka dace don hana ƙara abubuwan da ba a so daga tarkace ko wasu kayan da ake amfani da su a aikin ƙera ƙarfe. | |||||||

| a Duba zaɓi na 2. b Wannan buƙatar ba ta aiki ba muddin ƙarfen ya ƙunshi isasshen adadin wasu abubuwan da ke ɗaure nitrogen, kamar Ti, Nb ko V. Idan an ƙara shi, za a bayar da rahoton abubuwan da ke cikin waɗannan abubuwan a cikin takardar dubawa. Lokacin amfani da titanium, masana'anta za su tabbatar da cewa (Al + Ti/2) ≥ 0,020. | |||||||

Zaɓi na 2: Ga matakan ƙarfe E235 da E355, an ƙayyade yawan sinadarin sulfur mai sarrafawa daga 0,015% zuwa 0,040% don tallafawa injin. Za a same shi ta hanyar sake haɗa sinadarin sulfur bayan an gama cire sinadarin ko kuma ta hanyar amfani da ƙarancin iskar oxygen.

Zaɓi na 3: Sinadarin sinadaran da aka ƙayyade na ƙarfe ya kamata ya zama wanda ya dace da yin amfani da galvanizing mai zafi (duba misali EN ISO 1461 ko EN ISO 14713-2 don jagora).

Tebur na 3 da Tebur A.2 sun ƙayyade bambancin da aka yarda da shi na nazarin samfur daga iyakokin da aka ƙayyade akan nazarin simintin da aka bayar a Tebur na 2 da Tebur A.1

Tebur na 3 — Bambancin da aka yarda da shi na nazarin samfurin daga iyakokin da aka ƙayyade akan nazarin simintin da aka bayar a Tebur na 2

| Sinadarin | Ƙimar iyakancewa ga 'yan wasa | Bambancin da aka yarda da shi na nazarin samfurin |

| C | ≤0,22 | +0,02 |

| Si | ≤0,55 | +0,05 |

| Mn | ≤1,60 | +0,10 |

| P | ≤0,025 | +0,005 |

| S | ≤0,040 | ±0,005 |

| Al | ≥0,015 | -0,005 |

EN 10305 Bututun Karfe Mara Sumul Kayan Inji

Properties na injiEN 10305Bututun ƙarfe marasa tsari, waɗanda aka auna a zafin ɗaki, sune kamar haka. Waɗannan ƙimar sun dogara ne akan matakin ƙarfe da yanayin isarwa:

Tebur na 4 — Halayen inji a zafin ɗaki

| Karfe aji | Mafi ƙarancin ƙima don yanayin isarwaa | ||||||||||||

| +Cb | +LCb | +SR | +Ac | +N | |||||||||

| Karfe | Karfe | Rm | A | Rm | A | Rm | ReH | A | Rm | A | Rm | ReHd | A |

| suna | lamba | MPa | % | MPa | % | MPa | MPa | % | MPa | % | MPa | MPa | % |

| E215 | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | Daga 290 zuwa 430 | 215 | 30 |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | Daga 340 zuwa 480 | 235 | 25 |

| E355 | 1.058 | 640 | 4 | 580 | 7 | 580 | 450e | 10 | 450 | 22 | Daga 490 zuwa 630 | 355 | 22 |

| a Rm: ƙarfin juriya; ReH: ƙarfin yawan amfanin ƙasa na sama (amma duba 11.1); A: tsawaita bayan karyewa. Don alamun yanayin isarwa duba Tebur 1 | |||||||||||||

| b Dangane da matakin aikin sanyi a lokacin kammala aikin, ƙarfin yawan amfanin ƙasa zai iya kusan zama kamar ƙarfin juriya. Don dalilai na lissafi, ana ba da shawarar waɗannan alaƙar: -don yanayin isarwa +C: ReH≥0,8 Rm; —don yanayin isarwa +LC: ReH≥0,7 Rm. | |||||||||||||

| c Don dalilai na lissafi ana ba da shawarar alaƙar da ke ƙasa: ReH≥0.5 Rm. | |||||||||||||

| d Ga bututu masu diamita na waje ≤30mm da kauri na bango ≤3mm ReHmafi ƙarancin ƙima sun yi ƙasa da 10MPa fiye da ƙimar da aka bayar a cikin wannan tebur. | |||||||||||||

| e Ga bututun da diamita na waje> 160mm: ReH≥420MPa. | |||||||||||||

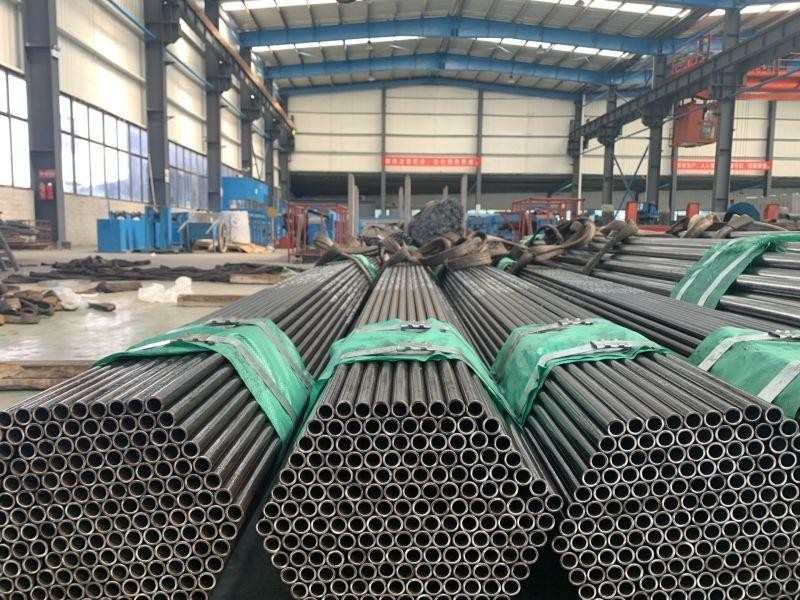

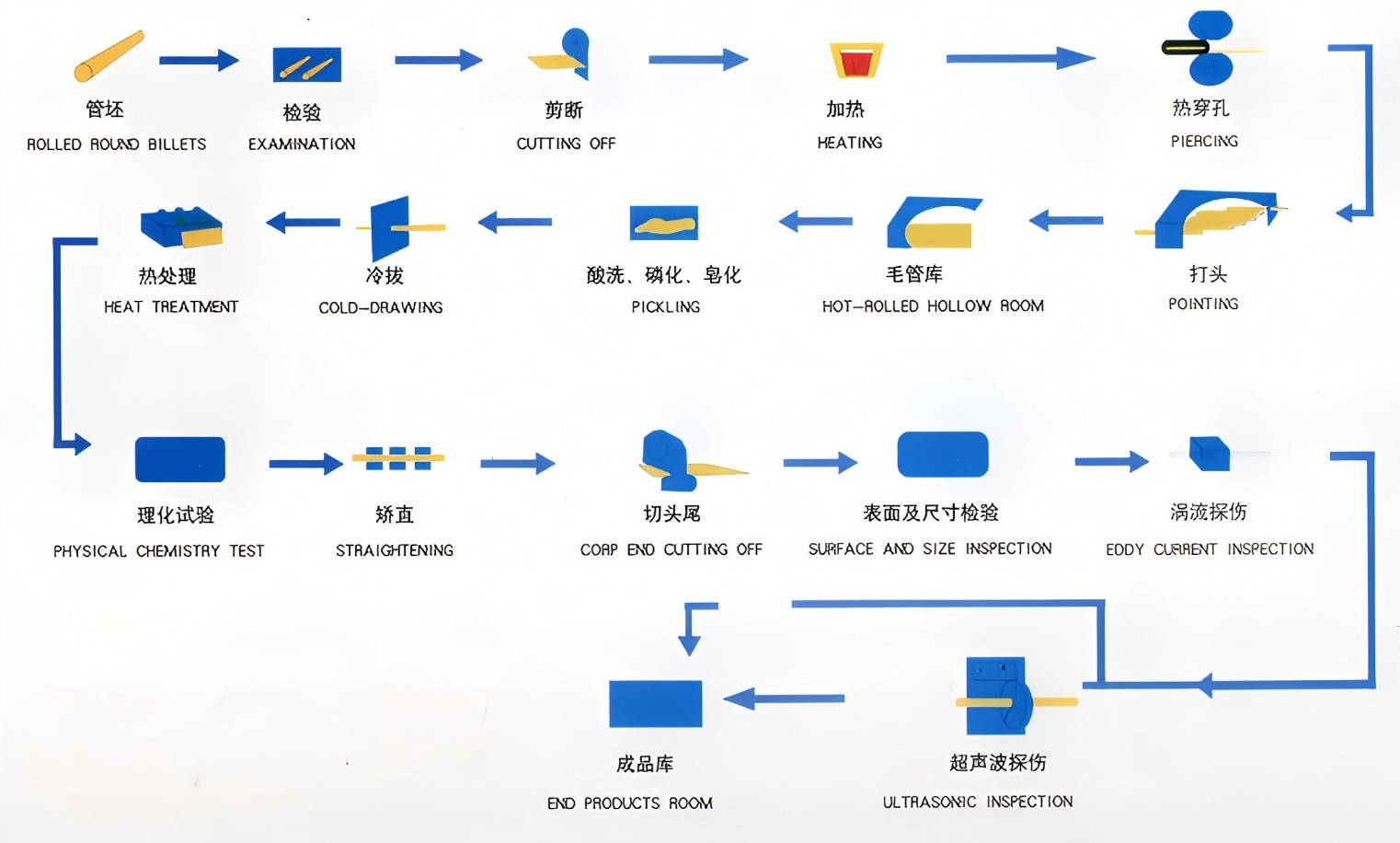

Tsarin Kera Bututun Karfe na EN 10305

Kamfanin Womic Steel yana amfani da dabarun kera kayayyaki na zamani don samar da kayayyaki.TS EN 10305 bututun ƙarfe marasa tsari, tabbatar da inganci mai kyau, kuma an ƙera shi daidai gwargwado. Tsarin ya ƙunshi waɗannan manyan matakai:

- Zaɓin Billet da Dubawa:

Tsarin kera yana farawa da ƙarfe mai inganci, ana duba shi sosai don tabbatar da daidaito da daidaiton kayan aiki. - Dumamawa & Hudawa:

Ana dumama billet ɗin zuwa yanayin zafi mafi kyau sannan a huda su don samar da bututu mai rami, wanda ke shirya su don ƙarin siffa. - Mai Zafi:

Ana yin birgima mai zafi don siffanta bututun, yana daidaita girman samfurin ƙarshe. - Zane Mai Sanyi:

Ana amfani da bututun da aka yi amfani da su wajen yin amfani da zafi wajen cire su cikin sanyi a ƙarƙashin yanayin da aka tsara domin cimma daidaiton diamita da kauri na bango. - Pickling:

Bayan an yi zane mai sanyi, ana cire bututun don cire duk wani sikeli na saman ko yadudduka na oxide, wanda ke tabbatar da tsabta da santsi. - Maganin Zafi:

Ana amfani da bututun wajen magance zafi kamar su annashuwa, wanda hakan ke inganta halayen injina kuma yana tabbatar da daidaito. - Daidaitawa da Yankewa:

Ana miƙe bututun kuma a yanka su zuwa tsawon da ake buƙata, don haka suna kiyaye daidaito da daidaito. - Dubawa & Gwaji:

Ana gudanar da bincike mai tsauri, gami da duba girma, gwaje-gwajen inji, da gwaje-gwaje marasa lalata (NDT), don tabbatar da mafi girman ƙa'idodi masu inganci.

Gwaji & Dubawa

Kamfanin Womic Steel yana ba da garantin mafi girman matakan tabbatar da inganci da kuma bin diddigin sa ta hanyar cikakkun hanyoyin gwaji donTS EN 10305 bututun ƙarfe marasa tsariWaɗannan sun haɗa da:

- Dubawa Mai Girma:

Auna diamita na waje, kauri na bango, tsayi, siffar da ta dace, da kuma madaidaiciyar siffa. - Gwajin Inji:

Ya haɗa da gwaje-gwajen tensile, gwaje-gwajen tasiri, da gwaje-gwajen tauri don tabbatar da ƙarfi da juriya da ake buƙata. - Gwajin da Ba Ya Lalacewa (NDT):

Gwajin halin yanzu na Eddy don gano lahani na ciki, gwajin ultrasonic (UT) don kauri bango da ingancin tsarin. - Binciken Sinadarai:

Ana tabbatar da abun da ke cikin kayan ta amfani da hanyoyin nazarin bayanai don tabbatar da cewa kayan ya cika ƙa'idodin da ake buƙata. - Gwajin Hydrostatic:

Ana gwada matsin lamba na ciki don tabbatar da cewa bututun zai iya jure matsin lamba na aiki ba tare da gazawa ba.

Dakin gwaje-gwaje & Kula da Inganci

Kamfanin Womic Steel yana gudanar da wani dakin gwaje-gwaje na zamani wanda aka sanye shi da kayan aikin gwaji na zamani don gudanar da bincike mai zurfi kan inganci. Ƙungiyarmu ta fasaha tana gudanar da bincike na yau da kullun akan kowane rukuni na kayan aiki.TS EN 10305 bututun ƙarfe marasa tsaridomin tabbatar da bin ƙa'idodin ƙasashen duniya masu tsauri. Muna kuma haɗa kai da hukumomin gwaji na ɓangare na uku don samar da tabbatar da ingancin bututun mai zaman kansa.

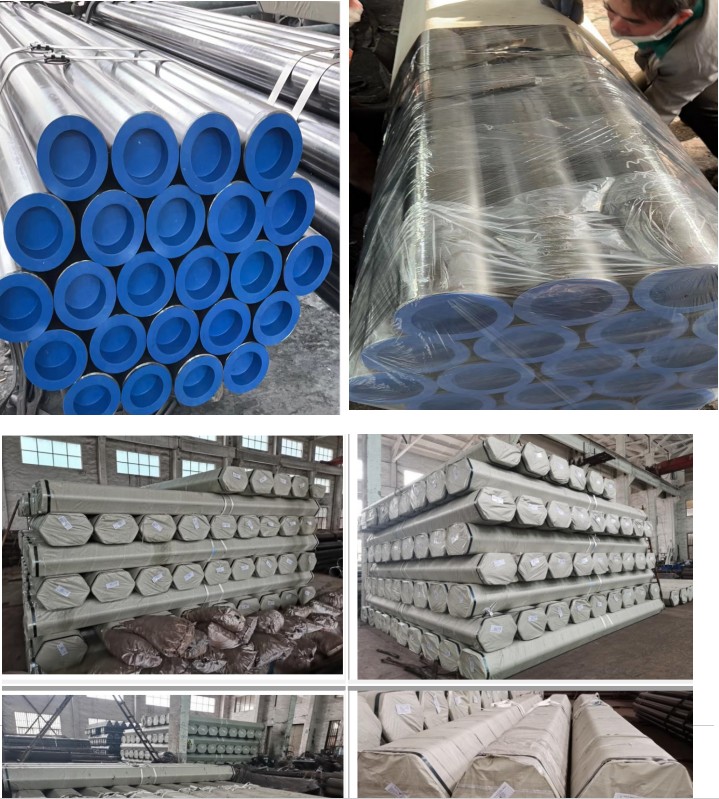

Marufi

TheTS EN 10305 bututun ƙarfe marasa tsariAna sanya su cikin na'urar a hankali domin tabbatar da cewa jigilar su lafiya da kuma isar da su.

- Rufin Kariya:

Kowace bututu an shafa mata wani Layer mai kariya daga tsatsa domin hana tsatsa da kuma gurbata muhalli yayin jigilar kaya da ajiya. - Manyan Maɓallan Ƙarshe:

Ana shafa murfin roba ko ƙarfe a ƙarshen bututun biyu don hana gurɓatawa, danshi, ko lalacewar jiki. - Haɗawa:

Ana haɗa bututun tare da madaurin ƙarfe ko madaurin filastik don kiyaye daidaito da kuma hana juyawa yayin jigilar kaya. - Rage Naɗewa:

Ana naɗe faifan a cikin fim mai laushi don kare bututun daga ƙura, datti, da sauran abubuwan muhalli. - Ganowa da Lakabi:

Kowace fakitin an yi mata lakabi da cikakkun bayanai game da samfurin, gami da matakin ƙarfe, girma, lambar batch, adadi, da duk wani umarni na musamman na sarrafawa.

Sufuri

Womic Steel yana tabbatar da isar da kayayyaki cikin lokaci da inganci a duk duniyaTS EN 10305 bututun ƙarfe marasa tsaritare da waɗannan hanyoyin sufuri:

Jirgin Ruwa:

Don jigilar kaya daga ƙasashen waje, ana ɗora bututun a cikin kwantena ko rakodi masu faɗi sannan a aika su zuwa kowace wuri a duniya.

Sufurin Jirgin Kasa da Hanya:

Don jigilar kayayyaki na cikin gida da na yanki, ana ɗora bututun a kan manyan motoci ko kwantena kuma ana jigilar su ta hanya ko layin dogo.

Kula da Yanayi:

Idan ya zama dole, za mu iya shirya jigilar kayayyaki ta hanyar amfani da yanayi domin kare bututun daga mummunan yanayi.

Takardu & Inshora:

An bayar da cikakkun takardu don share kwastam, jigilar kaya, da bin diddigin kayayyaki, kuma ana iya shirya inshora don jigilar kaya zuwa ƙasashen waje don kare kai daga lalacewa ko asara.

Fa'idodin Zaɓar Womic Steel

Daidaita Manufacturing:

Muna kula da dukkan hanyoyin masana'antu don biyan buƙatun daidaito.

Keɓancewa:

Zaɓuɓɓuka masu sassauƙa don tsawon bututu, maganin saman, da marufi bisa ga ƙayyadaddun buƙatun abokin ciniki.

Gwaji Mai Cikakke:

Gwaji mai tsauri yana tabbatar da cewa kowace bututu ta cika ƙa'idodin injiniya, sinadarai, da girma da ake buƙata.

Isarwa ta Duniya:

Isarwa mai inganci da kuma kan lokaci, duk inda aikinka yake.

Ƙwararren Ƙungiya:

Injiniyoyin ƙwararru da masu fasaha suna tabbatar da mafi girman ingancin samarwa da kuma ƙa'idodin sabis na abokin ciniki.

Kammalawa

Kamfanin Womic SteelEN 10305 Bututun Karfe Mara Sumulan tsara su ne don samar da ƙarfi, aminci, da daidaito ga aikace-aikace masu yawa masu wahala. Tare da jajircewarmu ga inganci, masana'antu na ci gaba, da gamsuwar abokan ciniki, mu ne amintaccen abokin tarayya don mafita na bututu marasa matsala a duk duniya.

Zaɓi Womic Steel don nakaEN 10305 Bututun Karfe Mara Sumulkuma ku fuskanci samfuran da suka yi aiki mai kyau waɗanda ke da ƙwarewa mara misaltuwa.

Don ƙarin bayani, tuntuɓe mu kai tsaye:

Yanar Gizo: www.womicsteel.com

Imel: sales@womicsteel.com

Waya/WhatsApp/WeChat: Victor: +86-15575100681 ko Jack: +86-18390957568