Bayanin Samfurin

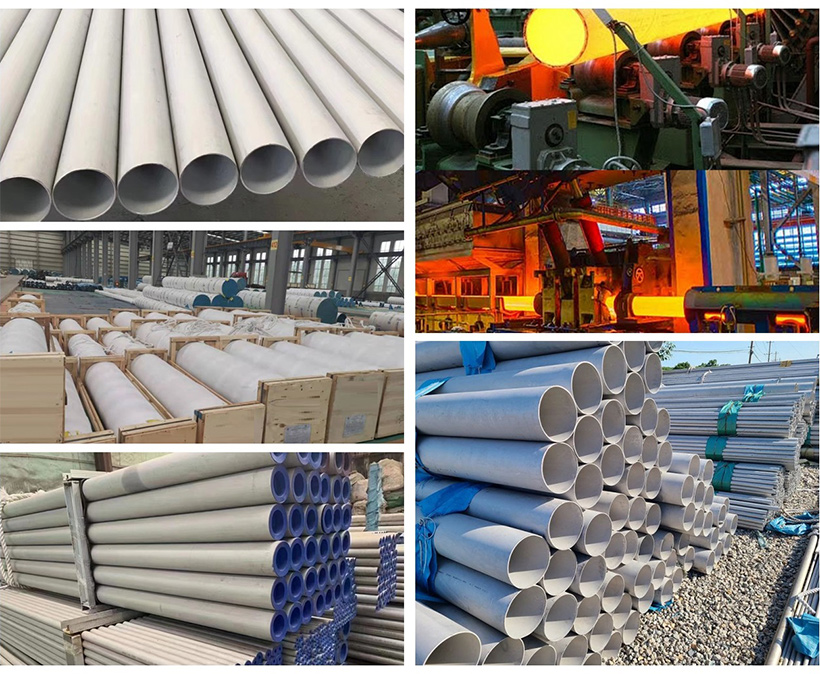

Bututun ƙarfe marasa shinge suna da matuƙar muhimmanci a aikace-aikacen masana'antu na zamani, waɗanda aka san su da juriyar tsatsa, da kuma gina su ba tare da wata matsala ba. Sun ƙunshi ƙarfe na musamman, chromium, da sauran abubuwa kamar nickel da molybdenum, waɗannan bututun suna nuna ƙarfi da tsawon rai mara misaltuwa.

Tsarin kera bututun ƙarfe mara matsala ya ƙunshi fitar da bututun ƙarfe masu ƙarfi don samar da bututun da ba su da ramuka ba tare da haɗin welded ba. Wannan hanyar gini tana kawar da raunin da ka iya samu kuma tana haɓaka ingancin tsarin, wanda ke sa bututun ƙarfe marasa sumul su zama abin dogaro ga aikace-aikace daban-daban.

Muhimman Halaye:

Juriyar Tsatsa:Haɗa sinadarin chromium yana samar da wani tsari mai kariya daga iskar oxygen, wanda ke kare bututun daga tsatsa da tsatsa ko da a cikin mawuyacin yanayi.

Maki daban-daban:Ana samun bututun ƙarfe marasa sumul a matakai daban-daban kamar 304, 316, 321, da 347, kowannensu an tsara shi ne don takamaiman aikace-aikace saboda bambancin abubuwan da ke cikin sinadarai da halayen injiniya.

Faɗin Aikace-aikace:Waɗannan bututun suna samun amfani a fannoni daban-daban, ciki har da mai da iskar gas, sarrafa sinadarai, abinci da abin sha, magunguna, motoci, da gine-gine. Sauƙin daidaitawarsu ga yanayi da abubuwa daban-daban yana nuna sauƙin amfani da su.

Girman da Kammalawa:Bututun ƙarfe marasa sulke suna zuwa da girma dabam-dabam, suna biyan buƙatu daban-daban. Bututun kuma suna iya samun ƙarewar saman daban-daban, tun daga gogewa zuwa ƙarewar niƙa, bisa ga buƙatun amfani.

Shigarwa da Gyara:Tsarin da ba shi da matsala yana sauƙaƙa shigarwa yayin da juriyar bututun ga tsatsa ke rage buƙatun kulawa, wanda ke ba da gudummawa ga inganci da farashi.

Tun daga sauƙaƙe jigilar mai da iskar gas zuwa samar da ingantattun sinadarai da kuma kiyaye tsaftar kayayyakin magunguna, bututun ƙarfe marasa shinge suna taka muhimmiyar rawa wajen tsara masana'antu a duk duniya. Haɗinsu na ƙarfi, juriya, da juriya ga abubuwan da suka shafi muhalli ya sa su zama abin dogaro a fannin injiniyanci da kayayyakin more rayuwa na zamani.

Bayani dalla-dalla

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H da sauransu... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 da dai sauransu. |

| DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 da dai sauransu... |

| JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB da sauransu... |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Bakin karfe mai suna Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Bakin Karfe Duplex:S31803, S32205, S32750, S32760, S32707, S32906... Alloy na Nickel:N04400, N06600, N06625, N08800, N08810(800H), N08825... Amfani:Masana'antun mai, sinadarai, iskar gas, wutar lantarki da kayan aikin injiniya. |

| NB | Girman | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 |

Daidaitacce & Matsayi

| Daidaitacce | Karfe maki |

| ASTM A312/A312M: Bututun Bakin Karfe Mara Sumul, Mai Walda, da Sanyi Mai Yawa | 304, 304L, 310S, 310H, 316, 316L, 321, 321H da sauransu... |

| ASTM A213: Tukwane na ƙarfe mai ferritic da austenitic, superheater, da bututun musayar zafi mara sulke | TP304, TP304L, TP316, TP316L, TP321.TP347 da sauransu... |

| ASTM A269: Bututun bakin karfe mara sumul da walda don hidima ta gaba ɗaya | TP304, TP304L, TP316, TP316L, TP321.TP347 da sauransu... |

| ASTM A789: Bututun ƙarfe mara sumul da welded ferritic/austenitic don sabis na gabaɗaya | S31803 (Bakin ƙarfe mai duplex) S32205 (Bakin ƙarfe mai duplex) |

| ASTM A790: Bututun ƙarfe mai kama da ferritic/austenitic mara sumul da kuma welded don hidimar lalata gabaɗaya, sabis mai zafi mai yawa, da bututun ƙarfe mai kama da duplex. | S31803 (Bakin ƙarfe mai duplex) S32205 (Bakin ƙarfe mai duplex) |

| EN 10216-5: Ma'aunin Turai don Bututun Karfe Mara Sumul don Matsi | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 da sauransu... |

| DIN 17456: Ma'aunin Jamusanci don bututun ƙarfe mara madauwari | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 da sauransu... |

| JIS G3459: Ma'aunin Masana'antu na Japan don Bututun Bakin Karfe don Juriyar Tsatsa | SUS304TB, SUS304LTB, SUS316TB, SUS316LTB da sauransu... |

| GB/T 14976: Ma'aunin Ƙasa na China don Bututun Karfe Mara Sumul don Sufuri Mai Ruwa | 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Bakin ƙarfe mai ƙarfi: TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Bakin ƙarfe mai duplex: S31803, S32205, S32750, S32760, S32707, S32906... Alloy na Nickel:N04400, N06600, N06625, N08800, N08810(800H), N08825... Amfani: Masana'antun Man Fetur, Sinadarai, Iskar Gas, Wutar Lantarki da kayan aikin Inji. | |

Tsarin Masana'antu

Tsarin Bututun Karfe Mai Zafi (Mai Fitar da Bututun Karfe Mara Sumul):

Bututun zagaye billet → dumama → huda → birgima mai birgima uku, ci gaba da birgima ko fitarwa → cire bututu → girma (ko rage diamita) → sanyaya → daidaita → gwajin hydraulic (Ko gano lahani) →alama → ajiya

Tsarin Tube na Karfe Mai Sanyi (Naɗewa) Mara Sumul:

Bututun zagaye billet → dumama → rami → kan → annealing → tsinken → mai (rufin jan ƙarfe) → zane mai sanyi mai wucewa da yawa (birgima mai sanyi) → billet → maganin zafi → daidaita → Gwajin na'urar lantarki (gano lahani) → Alama → Ajiya.

Sarrafa Inganci

Duba Kayan Danye, Binciken Sinadarai, Gwajin Inji, Duba Gani, Duba Girma, Gwajin Lanƙwasa, Gwajin Tasiri, Gwajin Tsatsa Tsakanin Granular, Gwajin Ƙarƙashin Ƙasa da Faɗi (UT, MT, PT), Gwajin Tauri, Gwajin Matsi, Gwajin Abubuwan Ferrite, Gwajin Ƙarfe, Gwajin Tsatsa, Gwajin Eddy Current, Gwajin Fesa Gishiri, Gwajin Juriyar Tsatsa, Gwajin Girgiza, Gwajin Tsatsa, Gwajin Tsatsa, Gwajin Tsatsa, Gwajin Tsatsa, Zane da Duba Shafi, Bitar Takardu…..

Amfani & Aikace-aikace

Bututun bakin karfe marasa sumul abu ne mai matuƙar muhimmanci da ake amfani da shi a fannoni daban-daban saboda juriyar tsatsa, ƙarfinsu mai yawa, da kuma ikon jure yanayin zafi mai tsanani. Ga wasu manyan aikace-aikacen bututun bakin karfe marasa sumul:

Masana'antar Mai da Iskar Gas:Ana amfani da bututun ƙarfe marasa sulke a fannin binciken mai da iskar gas, sufuri, da sarrafawa. Ana amfani da su don yin ramuka a rijiyoyi, bututun mai, da kayan aikin sarrafawa saboda juriyarsu ga tsatsa daga ruwa da iskar gas.

Masana'antar Sinadarai:A fannin sarrafa sinadarai da ƙera su, ana amfani da bututun ƙarfe marasa shinge don isar da sinadarai, tushe, sinadarai masu narkewa, da sauran abubuwa masu lalata. Suna ba da gudummawa ga aminci da amincin tsarin bututun.

Masana'antar Makamashi:Bututun bututun ƙarfe marasa shinge suna taka muhimmiyar rawa a samar da makamashi, gami da makamashin nukiliya, ƙwayoyin mai, da ayyukan makamashin da ake sabuntawa, don bututun mai da kayan aiki.

Masana'antar Abinci da Abin Sha:Godiya ga tsafta da juriyar tsatsa, ana amfani da bututun bakin karfe marasa shinge sosai wajen sarrafa abinci da samar da abin sha, gami da jigilar ruwa, iskar gas, da kayan abinci.

Masana'antar Magunguna:A fannin kera magunguna da samar da magunguna, ana amfani da bututun bakin karfe marasa sumul don jigilar da sarrafa sinadaran magunguna, biyan ka'idojin tsafta da inganci.

Gina Jirgin Ruwa:Ana amfani da bututun ƙarfe marasa sulke wajen gina jiragen ruwa don gina tsarin jiragen ruwa, tsarin bututun mai, da kayan aikin tace ruwan teku, saboda juriyarsu ga lalata muhallin ruwa.

Kayan Gine-gine da Gine-gine:Ana amfani da bututun ƙarfe marasa sulke da ake amfani da su wajen gini don bututun samar da ruwa, tsarin HVAC, da kayan aikin ado.

Masana'antar Motoci:A fannin kera motoci, bututun ƙarfe marasa shinge suna samun aikace-aikace a tsarin shaye-shaye saboda juriyarsu ga yanayin zafi mai yawa da kuma juriyar tsatsa.

Haƙar ma'adinai da aikin ƙarfe:A fannin hakar ma'adinai da kuma fannin karafa, ana amfani da bututun ƙarfe marasa shinge don jigilar ma'adanai, slurries, da kuma maganin sinadarai.

A taƙaice, bututun ƙarfe marasa sumul suna da amfani kuma suna ba da kyakkyawan aiki, wanda hakan ya sa suka dace da masana'antu daban-daban. Suna taka muhimmiyar rawa wajen tabbatar da amincin tsari, haɓaka amincin kayan aiki, da kuma tsawaita tsawon rai. Aikace-aikace daban-daban suna buƙatar bututun ƙarfe marasa sumul tare da takamaiman ƙayyadaddun bayanai da kayan aiki don biyan buƙatunsu na musamman.

Shiryawa & Jigilar Kaya

Ana naɗe bututun ƙarfe masu bakin ƙarfe kuma ana jigilar su da matuƙar kulawa don tabbatar da kariyarsu yayin jigilar kaya. Ga bayanin yadda ake shirya marufi da jigilar kaya:

Marufi:

● Rufin Kariya: Kafin a rufe bututun bakin karfe, galibi ana shafa musu mai ko fim mai kariya domin hana tsatsa da lalacewa a saman bututun.

● Haɗawa: Ana haɗa bututu masu girma da ƙayyadaddun abubuwa iri ɗaya tare a hankali. Ana ɗaure su ta amfani da madauri, igiyoyi, ko madaurin filastik don hana motsi a cikin madaurin.

● Murfin Ƙarshe: Ana sanya murfin ƙarshen roba ko ƙarfe a ƙarshen bututun biyu don samar da ƙarin kariya ga ƙarshen bututun da zare.

● Famfo da Famfo: Ana amfani da kayan famfo kamar kumfa, kumfa, ko kwali mai rufi don samar da matashin kai da kuma hana lalacewar tasiri yayin jigilar kaya.

● Akwatunan Katako ko Akwatunan: A wasu lokuta, ana iya sanya bututu a cikin akwatunan katako ko akwatunan don samar da ƙarin kariya daga ƙarfin waje da sarrafawa.

Jigilar kaya:

● Yanayin Sufuri: Ana jigilar bututun bakin ƙarfe ta amfani da hanyoyi daban-daban na sufuri kamar manyan motoci, jiragen ruwa, ko jigilar jiragen sama, ya danganta da inda ake zuwa da kuma gaggawar da ake buƙata.

● Sanya bututu a cikin kwantena: Ana iya loda bututu a cikin kwantena na jigilar kaya don tabbatar da aminci da tsari na jigilar kaya. Wannan kuma yana ba da kariya daga yanayin yanayi da gurɓatattun abubuwa na waje.

● Lakabi da Takardu: Kowace fakitin an yi mata lakabi da muhimman bayanai, gami da ƙayyadaddun bayanai, adadi, umarnin sarrafawa, da cikakkun bayanai game da inda za a je. Ana shirya takardun jigilar kaya don share kwastam da bin diddigin su.

● Bin Dokokin Kwastam: Don jigilar kaya zuwa ƙasashen waje, an shirya duk takaddun kwastam da ake buƙata don tabbatar da an share su cikin sauƙi a inda za a kai su.

● Maƙallin Tsaro: A cikin motar sufuri ko akwati, ana ɗaure bututu da ƙarfi don hana motsi da rage haɗarin lalacewa yayin jigilar kaya.

● Bin diddigi da Kulawa: Ana iya amfani da ingantattun tsarin bin diddigi don sa ido kan wurin da kuma yanayin jigilar kaya a ainihin lokaci.

● Inshora: Dangane da darajar kayan, ana iya samun inshorar jigilar kaya don biyan asarar da za a iya samu ko lalacewa yayin jigilar kaya.

A taƙaice, za a naɗe bututun ƙarfe na bakin ƙarfe da muka samar da su da matakan kariya sannan a aika su ta amfani da hanyoyin sufuri masu inganci don tabbatar da cewa sun isa inda za su je cikin yanayi mafi kyau. Tsarin marufi da jigilar kaya masu kyau suna taimakawa wajen sahihanci da ingancin bututun da aka kawo.