Bayanin Samfurin

Bututun ƙarfe mai karkace, wanda kuma aka sani da bututun helical submerged arc-welded (HSAW), wani nau'in bututun ƙarfe ne wanda aka siffanta shi da tsarin kera su da kuma halayensu na tsari. Ana amfani da waɗannan bututun sosai a masana'antu daban-daban saboda ƙarfinsu, juriyarsu, da kuma sauƙin daidaitawa. Ga cikakken bayani game da bututun ƙarfe mai karkace:

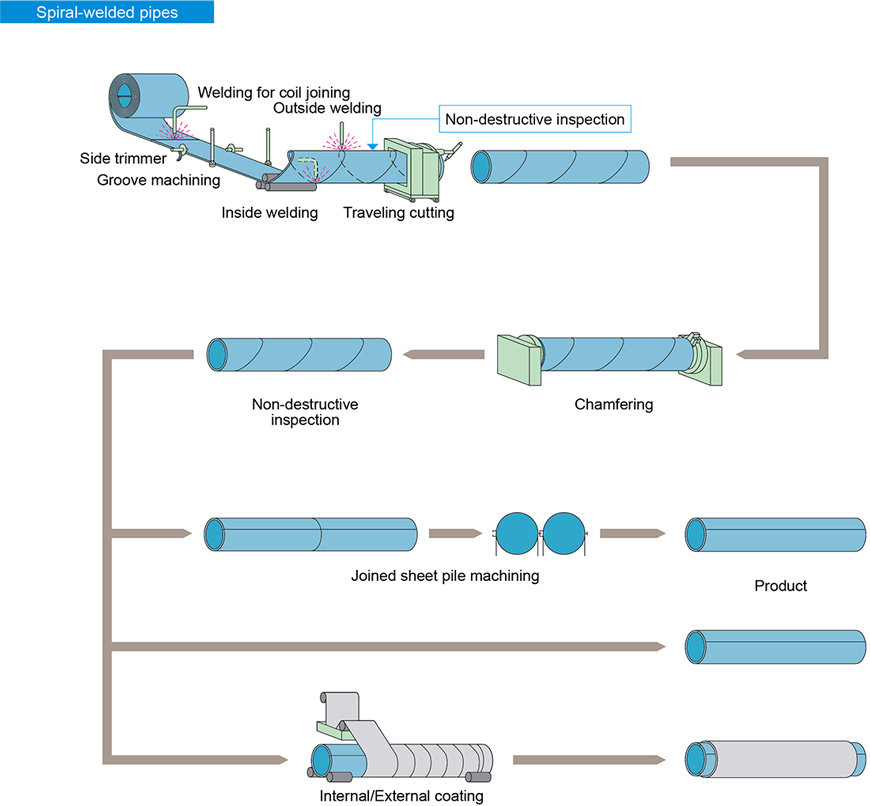

Tsarin Masana'antu:Ana samar da bututun ƙarfe mai karkace ta hanyar wani tsari na musamman wanda ya haɗa da amfani da na'urar zare ta ƙarfe. Ana cire zare ɗin kuma a samar da shi zuwa siffar karkace, sannan a haɗa shi ta amfani da dabarar walda ta baka (SAW) da ke ƙarƙashin ruwa. Wannan tsari yana haifar da dinkin helical mai ci gaba da tafiya a kan tsawon bututun.

Tsarin Gine-gine:Dinkin bututun ƙarfe mai siffar helical yana ba da ƙarfi na asali, wanda hakan ya sa suka dace da jure wa manyan kaya da matsin lamba. Wannan ƙirar tana tabbatar da rarraba damuwa iri ɗaya kuma tana haɓaka ikon bututun na tsayayya da lanƙwasawa da nakasa.

Girman Girma:Bututun ƙarfe masu karkace suna zuwa da diamita iri-iri (har zuwa inci 120) da kauri, wanda ke ba da damar sassauci a aikace-aikace daban-daban. Ana samun su galibi a cikin manyan diamita idan aka kwatanta da sauran nau'ikan bututu.

Aikace-aikace:Ana amfani da bututun ƙarfe mai karkace a masana'antu daban-daban kamar mai da iskar gas, samar da ruwa, gini, noma, da kuma haɓaka ababen more rayuwa. Sun dace da amfani a sama da ƙasa.

Juriyar Tsatsa:Domin ƙara tsawon rai, bututun ƙarfe masu karkace galibi ana yi musu maganin hana lalata. Waɗannan na iya haɗawa da shafa na ciki da na waje, kamar epoxy, polyethylene, da zinc, waɗanda ke kare bututun daga abubuwan muhalli da abubuwan da ke lalata su.

Fa'idodi:Bututun ƙarfe masu karkace suna ba da fa'idodi da dama, waɗanda suka haɗa da ƙarfin ɗaukar kaya mai yawa, ingancin araha ga bututun mai girman diamita mai girma, sauƙin shigarwa, da kuma juriya ga nakasa. Tsarin su na helical kuma yana taimakawa wajen samar da ingantaccen magudanar ruwa.

Tsawon lokaciVSKarkace:Ana iya bambanta bututun ƙarfe masu karkace daga bututun da aka haɗa da haɗin kai ta hanyar tsarin ƙera su. Yayin da ake samar da bututun tsayi da kuma haɗa su a tsawon bututun, bututun karkace suna da ɗinkin helical da aka samar yayin ƙera su.

Sarrafa Inganci:Tsarin kera da kula da inganci suna da matuƙar muhimmanci wajen samar da ingantattun bututun ƙarfe masu karkace. Ana sa ido sosai kan sigogin walda, tsarin bututu, da hanyoyin gwaji don tabbatar da bin ƙa'idodi da ƙa'idodi na masana'antu.

Ma'auni da Bayanai:Ana ƙera bututun ƙarfe masu karkace bisa ga ƙa'idodin ƙasa da ƙasa da na masana'antu kamar API 5L, ASTM, EN, da sauransu. Waɗannan ƙa'idodi suna bayyana halayen kayan aiki, hanyoyin ƙera su, da buƙatun gwaji.

A taƙaice, bututun ƙarfe mai karkace mafita ce mai amfani da yawa kuma mai ɗorewa ga masana'antu daban-daban. Tsarin kera su na musamman, ƙarfin da ke tattare da su, da kuma samuwa a girma dabam-dabam suna ba da gudummawa ga amfani da su a fannoni daban-daban na ababen more rayuwa, sufuri, makamashi, gina tashar jiragen ruwa da sauransu. Zaɓi mai kyau, kula da inganci, da matakan kariya daga tsatsa suna taka muhimmiyar rawa wajen tabbatar da aikin bututun ƙarfe mai karkace na dogon lokaci.

Bayani dalla-dalla

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Daraja C250, Daraja C350, Daraja C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Diamita (mm) | Kauri a Bango (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Juriyar Diamita na Waje da Kauri a Bango

| Daidaitacce | Juriya ga Jikin Bututu | Juriyar Ƙarshen Bututu | Juriyar Kauri a Bango | |||

| Diamita Mai Fita | Haƙuri | Diamita Mai Fita | Haƙuri | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| OD> 508mm | ≤±1.0% | OD> 508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD> 941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ±0.75%D~±3mm | 60 | ±0.5%D~±1.6mm | 4mm | ±12.5%T~±15.0%T |

| 610 | ±0.5%D~±4mm | 610 | ±0.5%D~±1.6mm | WT≥25mm | -3.00mm~+3.75mm | |

| OD> 1430mm | - | OD> 1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD <508mm | ≤±0.75% | OD <508mm | ≤±0.75% | OD <508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD <60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | WT≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Inci | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm da sama da diamita na bututun bango Kauri mafi girma 25mm | ||||||||||||||||

Daidaitacce & Matsayi

| Daidaitacce | Karfe maki |

| API 5L: Bayani dalla-dalla game da Bututun Layi | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Takamaiman Bayani na Musamman don Tubalan Bututun Karfe Masu Walda da Mara Sumul | GR.1, GR.2, GR.3 |

| EN 10219-1: Sassan ƙarfe marasa ƙarfe da ƙananan hatsi da aka haɗa da tsarin walda mai sanyi | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Sassan Tsarin Gine-gine Masu Zafi Na Karfe Marasa Alloy da Kyawawan Hatsi | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Bututu, Karfe, Baƙi da kuma ruwan zafi, An rufe shi da Zinc, An haɗa shi da walda kuma ba shi da sumul | GR.A, GR.B |

| EN 10217: Bututun ƙarfe da aka haɗa da walda don dalilai na matsi | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Bututun ƙarfe da bututun da aka haɗa da walda | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Ma'aunin Australiya/New Zealand don Sassan Karfe Masu Sanyi da Aka Yi da Sanyi | Darasi C250, Darasi C350, Darasi C450 |

| GB/T 9711: Masana'antar Man Fetur da Iskar Gas - Bututun Karfe don Bututun | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| AWWA C200: Bututun Ruwa na Karfe Inci 6 (150 mm) da Ya Fi Girma | Karfe na Carbon |

Tsarin Masana'antu

Sarrafa Inganci

● Duba Kayan Danye

● Nazarin Sinadarai

● Gwajin Inji

● Duban Gani

● Duba Girma

● Gwajin Lanƙwasa

● Gwajin Tasiri

● Gwajin Tsatsa Tsakanin Granular

● Jarrabawar da ba ta lalata jiki ba (UT, MT, PT)

● Cancantar Tsarin Walda

● Binciken Tsarin Ƙananan Sifofi

● Gwajin Faɗaɗawa da Faɗaɗawa

● Gwajin Tauri

● Gwajin Matsi

● Gwajin Nazarin Ƙarfe

● Gwajin Tsatsa

● Gwajin Eddy na Yanzu

● Duba Zane da Rufi

● Bitar Takardu

Amfani & Aikace-aikace

Bututun ƙarfe masu karkace suna da amfani sosai kuma ana amfani da su sosai a masana'antu daban-daban saboda halaye da fa'idodinsu na musamman. Ana ƙirƙirar su ta hanyar haɗa sandunan ƙarfe tare don ƙirƙirar bututu mai dinkin karkace mai ci gaba. Ga wasu aikace-aikacen da aka saba amfani da su na bututun ƙarfe masu karkace:

● Sufurin Ruwa: Waɗannan bututun suna motsa ruwa, mai, da iskar gas cikin sauƙi ta hanyar amfani da hanyoyi masu nisa a cikin bututun saboda ƙarfinsu da kuma ƙarfinsu mai yawa.

● Mai da Iskar Gas: Yana da matuƙar muhimmanci ga masana'antun mai da iskar gas, suna jigilar ɗanyen mai, iskar gas, da kayayyakin da aka tace, suna biyan buƙatun bincike da rarrabawa.

● Tarin ginshiƙai: Tushen tushe a cikin ayyukan gini yana tallafawa manyan kaya a cikin gine-gine kamar gine-gine da gadoji.

● Amfani da Tsarin Gine-gine: Idan aka yi amfani da su wajen gina ginshiƙai, ginshiƙai, da tallafi, dorewarsu tana taimakawa wajen daidaita tsarin.

● Magudanar Ruwa da Magudanar Ruwa: Ana amfani da su a tsarin ruwa, juriyarsu ga tsatsa da kuma cikin gida mai santsi yana hana toshewa da kuma inganta kwararar ruwa.

● Bututun Inji: A fannin masana'antu da noma, waɗannan bututun suna ba da mafita masu inganci da inganci ga kayan aiki.

● Ruwa da Tekun Ruwa: Ga muhalli mai wahala, ana amfani da su a bututun ruwa na ƙarƙashin ruwa, dandamali na teku, da kuma gina jetty.

● Haƙar ma'adinai: Suna isar da kayayyaki da gurɓatattun abubuwa a cikin ayyukan haƙar ma'adinai masu wahala saboda ƙarfin gininsu.

● Samar da Ruwa: Ya dace da bututun mai girman diamita a tsarin ruwa, yana jigilar ruwa mai yawa yadda ya kamata.

● Tsarin Geothermal: Ana amfani da su a ayyukan makamashin geothermal, suna kula da canja wurin ruwa mai jure zafi tsakanin ma'ajiyar ruwa da tashoshin wutar lantarki.

Yanayin bututun ƙarfe mai karkace iri-iri, tare da ƙarfinsu, juriyarsu, da kuma sauƙin daidaitawa, ya sanya su zama muhimmin sashi a fannoni daban-daban na masana'antu da aikace-aikace.

Shiryawa & Jigilar Kaya

Shiryawa:

Tsarin tattara bututun ƙarfe mai karkace ya ƙunshi matakai da dama masu mahimmanci don tabbatar da cewa bututun suna da kariya sosai yayin jigilar kaya da ajiya:

● Haɗa Bututu: Ana haɗa bututun ƙarfe masu karkace tare ta amfani da madauri, madaurin ƙarfe, ko wasu hanyoyin ɗaurewa masu aminci. Haɗa bututu yana hana kowane bututu motsi ko canzawa a cikin marufi.

● Kariyar Ƙarshen Bututu: Ana sanya murfi na filastik ko murfin kariya a ƙarshen bututun biyu don hana lalacewar ƙarshen bututun da saman ciki.

● Kare Ruwa: Ana naɗe bututun da kayan hana ruwa shiga, kamar zanen filastik ko naɗewa, don kare su daga danshi yayin jigilar su, musamman a jigilar kaya ta waje ko ta teku.

● Famfo: Ana iya ƙara ƙarin kayan famfo, kamar kayan da aka saka kumfa ko kayan gyaran matashin kai, tsakanin bututun ko a wuraren da ba su da ƙarfi don shanye girgiza da girgiza.

● Lakabi: Kowace fakiti an yi mata lakabi da muhimman bayanai, gami da ƙayyadaddun bututu, girma, adadi, da inda za a je. Wannan yana taimakawa wajen gane da sarrafa su cikin sauƙi.

Jigilar kaya:

● Bututun ƙarfe masu kauri suna buƙatar tsari mai kyau don tabbatar da aminci da ingantaccen sufuri:

● Yanayin Sufuri: Zaɓin yanayin sufuri (hanya, layin dogo, teku, ko iska) ya dogara da abubuwa kamar nisan, gaggawa, da kuma isa ga inda za a je.

● Shigar da bututu: Ana iya loda bututun a cikin kwantena na jigilar kaya na yau da kullun ko kwantena na musamman masu faɗi. Shigar da bututun yana kare bututun daga abubuwan waje kuma yana samar da yanayi mai sarrafawa.

● Tsare-tsare: Ana ɗaure bututu a cikin kwantena ta amfani da hanyoyin ɗaurewa masu dacewa, kamar su ɗaurewa, toshewa, da kuma ɗaurewa. Wannan yana hana motsi kuma yana rage haɗarin lalacewa yayin jigilar kaya.

● Takardu: An shirya takardu masu inganci, gami da takardun kuɗi, jerin abubuwan da aka tattara, da takardun jigilar kaya, don tabbatar da kwastam da kuma bin diddigin su.

● Inshora: Sau da yawa ana samun inshorar kaya don biyan asarar da za a iya samu ko lalacewa yayin jigilar kaya.

● Kulawa: A duk lokacin jigilar kaya, ana iya bin diddigin bututu ta amfani da tsarin GPS da tsarin bin diddigi don tabbatar da cewa suna kan hanya da jadawalin da ya dace.

● Rage Albashi a Kwastam: An samar da ingantattun takardu don sauƙaƙe share fage na kwastam a tashar jiragen ruwa ko kan iyaka da za a kai.

Kammalawa:

Daidaiton marufi da jigilar bututun ƙarfe masu karkace yana da matuƙar muhimmanci don kiyaye ingancin bututun da kuma ingancinsa yayin jigilar su. Bin ƙa'idodin masana'antu mafi kyau yana tabbatar da cewa bututun sun isa inda suke a cikin yanayi mafi kyau, a shirye don shigarwa ko ci gaba da sarrafawa.